Índice

- Entendendo o couro PU: o que o torna único

- Materiais Essenciais do Couro PU: Base e Revestimento Explicados

- Importância da seleção de texturas: impacto na aparência e na sensação ao toque.

- Considerações sobre durabilidade: desgaste, ruptura e vida útil

- Selecionando o couro PU ideal para seus produtos: Soluções profissionais da Yudeng

Entendendo o couro PU: o que o torna único

O couro PU, também conhecido como couro sintético de poliuretano, é feito principalmente de poliuretano (PU) através de um processo de base e revestimento. Ele se assemelha muito ao couro genuíno em aparência e toque, oferecendo vantagens como impermeabilidade, resistência à abrasão e facilidade de limpeza, tornando-o um material ideal para móveis, interiores automotivos, roupas, calçados e bolsas.

Em comparação com o couro natural, o couro PU apresenta as seguintes características notáveis:

- Vantagem de custoO couro PU é mais barato de produzir do que o couro genuíno, e seu processo de fabricação pode ser altamente padronizado, sendo adequado para produção em massa.

- Alta capacidade de personalizaçãoO couro PU pode atingir diversas aparências e atender a diferentes requisitos funcionais, ajustando-se a espessura do revestimento, o design da textura e o material de base.

- Ecológico e sustentávelAo contrário de alguns tipos de couro PVC, o couro PU moderno é mais ecológico, com alguns produtos recicláveis ou produzidos com processos de baixo uso de solventes.

- Boa estabilidadeO couro natural pode deformar ou rachar devido a mudanças de temperatura e umidade, enquanto o couro PU permanece relativamente estável em diversos ambientes.

No entanto, o couro PU também apresenta algumas limitações, como resistência térmica limitada e potencial envelhecimento superficial sob uso intenso e prolongado. Portanto, compreender suas propriedades e escolher o material e a textura adequados é crucial.

Materiais Essenciais do Couro PU: Base e Revestimento Explicados

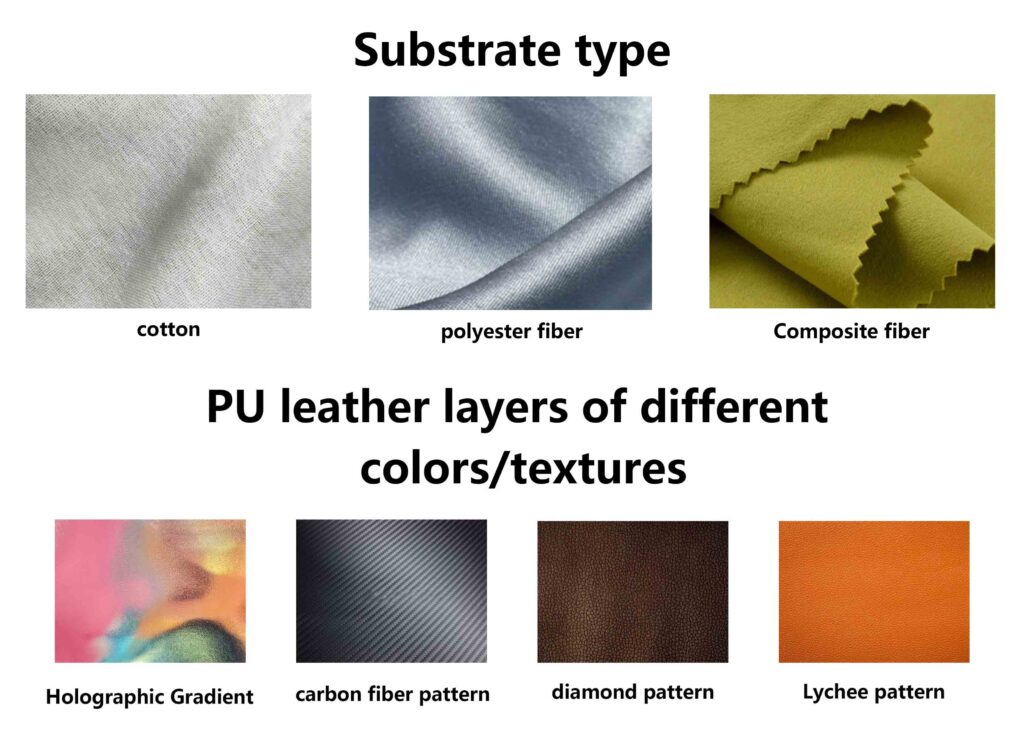

O desempenho do couro PU depende não apenas do seu revestimento superficial, mas também, e principalmente, do seu material de base. As bases são geralmente feitas de tecidos planos, tecidos de malha, tecidos não tecidos ou fibras compostas. Diferentes materiais de base determinam a flexibilidade, a resistência à tração e a durabilidade do couro PU.

Tipos e características dos materiais base

- Base de algodão: Macia e confortável, adequada para calçados e vestuário, mas com resistência à tração relativamente baixa.

- Base de poliéster: Alta resistência e durabilidade, ideal para bolsas, móveis e produtos que exigem uso prolongado.

- Base de fibra composta: Combina as vantagens de diferentes fibras para obter produtos leves, resistentes ao desgaste e com toque agradável.

Revestimento e tratamento de superfície

Os revestimentos de PU são formados por meio de processos de pulverização, imersão ou calandragem e podem alcançar diferentes efeitos visuais e características funcionais:

- Acabamento brilhante: Fácil de limpar, adequado para móveis modernos ou bolsas de alta qualidade.

- Textura em relevo ou semelhante a couro: Melhora a sensação ao toque e simula a aparência do couro genuíno.

- Revestimentos funcionais especiais: tratamento impermeável, resistente a óleo, resistente ao fogo ou antibacteriano para atender a necessidades específicas de aplicação.

Importância da seleção de texturas: impacto na aparência e na sensação ao toque.

A textura afeta não apenas o efeito visual do couro PU, mas também sua sensação ao toque e sua resistência ao desgaste. Texturas comuns de couro PU incluem:

- Acabamento liso: Superfície plana e brilhante, estilo moderno, fácil de limpar, mas suscetível a riscos.

- Padrão em relevo: Criado por meio de estampagem a quente ou mecânica, melhorando a sensação ao toque, a propriedade antiderrapante e a resistência ao desgaste.

- Efeito couro granulado: Simula a textura natural do couro, proporcionando uma sensação premium e maior conforto.

Dicas práticas de seleção:

- Teste de amostra: Avalie a maciez, a sensação tátil e o conforto pelo toque.

- Teste de desgaste: Esfregue levemente para simular as condições de uso e verificar se a textura descasca ou deforma com facilidade.

- Combinação visual: o estilo da textura deve harmonizar com o design geral do produto, por exemplo, texturas em relevo ou granuladas para bolsas, texturas lisas para capas de dispositivos eletrônicos.

A seleção científica de texturas ajuda a alcançar o melhor equilíbrio entre aparência, toque e durabilidade.

Considerações sobre durabilidade: desgaste, ruptura e vida útil

A durabilidade é um indicador fundamental da qualidade do couro PU. De acordo com testes de materiais e dados da indústria, o desempenho do couro PU em termos de resistência à abrasão, ao rasgo e à água é o seguinte:

- Resistência à abrasãoO couro PU padrão suporta de 30.000 a 50.000 ciclos no teste de abrasão Martindale, sendo adequado para móveis ou bolsas de uso frequente.

- Resistência ao rasgoO couro PU com base de poliéster possui resistência à tração de até 20-25 MPa, garantindo que não se rasgue facilmente no uso diário.

- Resistência à águaO couro PU revestido pode atingir a impermeabilização 100%, sendo adequado para produtos de uso externo ou propensos à umidade.

Métodos de teste de durabilidade:

- Teste de abrasão: simula o desgaste a longo prazo.

- Teste de envelhecimento: Observa as alterações na superfície sob alta temperatura e umidade.

- Teste de tração e rasgo: Avalia a resistência da ligação entre o material base e o revestimento.

Selecionando o couro PU ideal para seus produtos: Soluções profissionais da Yudeng

A escolha do couro PU certo depende não apenas do material e da textura, mas também da capacidade profissional de um fornecedor confiável. A Yudeng, com sua experiência, é uma empresa que oferece esse tipo de serviço. fornecedor de material PUOferece serviços de personalização abrangentes para ajudar os clientes a criar produtos ideais.

Vantagens de personalização do couro Yudeng PU

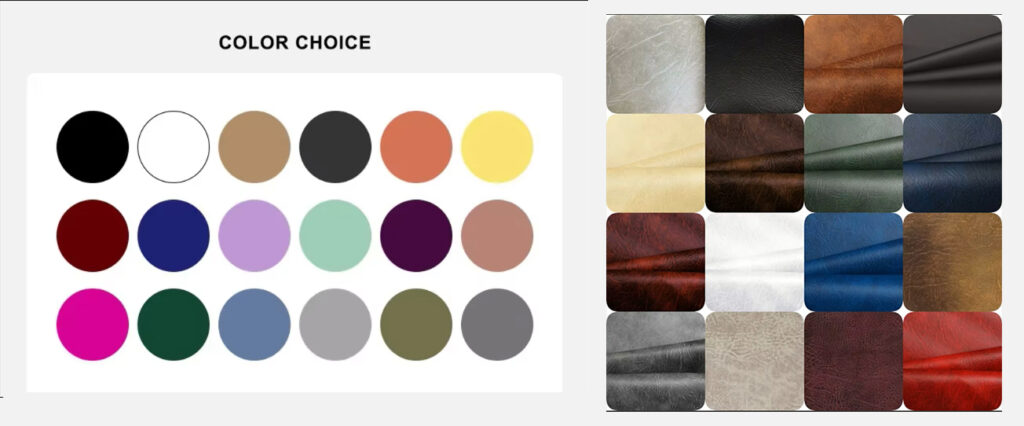

- Personalização de textura: Os designs podem ser adaptados para efeitos de couro brilhante, em relevo ou granulado, de acordo com as necessidades do cliente.

- Seleção do material base: Oferece opções em algodão, poliéster, fibra composta e outros materiais.

- Ajuste de espessura e revestimento: Otimizado para diferentes aplicações, buscando o equilíbrio entre maciez e durabilidade.

- Personalização em pequenos lotes: Permite testes de amostra para verificar rapidamente o material e a textura.

- Garantia de produção em massa: Equipamentos de produção avançados asseguram o fornecimento consistente para grandes encomendas.

Etapas de seleção

- Análise de requisitos: Definir o uso do produto, cenários de aplicação, aparência e requisitos táteis.

- Combinação de materiais: Escolha a base e o revestimento adequados com base na resistência ao desgaste, maciez e funcionalidade.

- Testes de amostra: Verificar a sensação tátil, o desgaste e a resistência à água para atender aos padrões.

- Confirmação em massa: Finalizar a solução e prosseguir com a produção em massa para garantir qualidade consistente.

Por meio desse processo, os clientes podem maximizar o desempenho do couro PU em móveis, calçados, bolsas e capas para dispositivos eletrônicos. A Yudeng, como fornecedora confiável, oferece soluções completas para esse fim. couro sintético por grosso O fornecedor possui vasta experiência e um sistema completo de controle de qualidade, oferecendo consultoria profissional e soluções personalizadas, ao mesmo tempo que minimiza os riscos de aquisição.

| Comece seu pedido | E-mail: hello@fjyudeng.com | Número: +86 17746077007 |

A seleção de couro PU de alta qualidade exige a consideração do material, da textura e da durabilidade. A escolha científica da base e do revestimento, a combinação de texturas adequadas, a realização de testes de durabilidade e o apoio da experiência e das capacidades de personalização de um fornecedor profissional são essenciais para garantir a qualidade do produto e a experiência do usuário.

Trabalhar com um fornecedor profissional como a Yudeng não só oferece diversas opções de couro PU, como também garante soluções personalizadas e transições tranquilas desde testes em pequenos lotes até a produção em massa. Essa abordagem ajuda seus produtos a terem uma aparência atraente, serem duráveis e se destacarem no mercado.

Durante o processo de aquisição, recomenda-se prestar atenção às qualificações profissionais e à experiência de couro sintético por grosso e fornecedor de material PU Empresas para garantir que você escolha o couro PU mais adequado para seus produtos. Seleção científica, personalização profissional e considerações de durabilidade são essenciais para a criação de produtos de alta qualidade.