Today, as the global manufacturing industry develops towards “personalization and high added value”, the demand for customized PU synthetic leather is continuing to grow. From shoes, bags, home furnishings, automotive interiors to electronic packaging, more and more brand companies and manufacturing plants are turning to customized PU materials. This is not only for a “different” visual experience, but also for multiple considerations of functionality, cost control and sustainability. Especially in the context of increasingly stringent environmental regulations and increasingly differentiated consumer markets, customized synthetic leather is no longer just the exclusive domain of big brands, but a key link for every pu leather manufacturer to achieve differentiated competition and increase product value.

The advantage of customized PU synthetic leather is that it can choose different leather grains, colors, feel, strength, wear resistance, flame retardancy, environmental protection level and other parameters according to product design requirements to ensure that the material is highly matched with the application scenario. This flexibility and sense of exclusivity are the core values that synthetic leather factory with mature customization capabilities such as Yudeng are good at.

Índice

- Structure and classification of PU synthetic leather

- What are the core parameters that determine the customization of PU synthetic leather?

- Customization process: Turn your ideas into reality

- How to make surface treatment and special performance customization more outstanding?

- Leather texture can be customized: a concerto of touch and vision

- A variety of PU leather backing substrates for you to choose

- What are the pitfalls in the process of customizing PU synthetic leather?

Structure and classification of PU synthetic leather

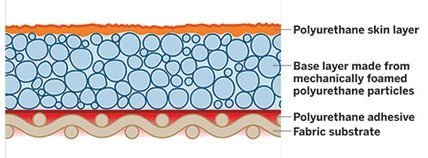

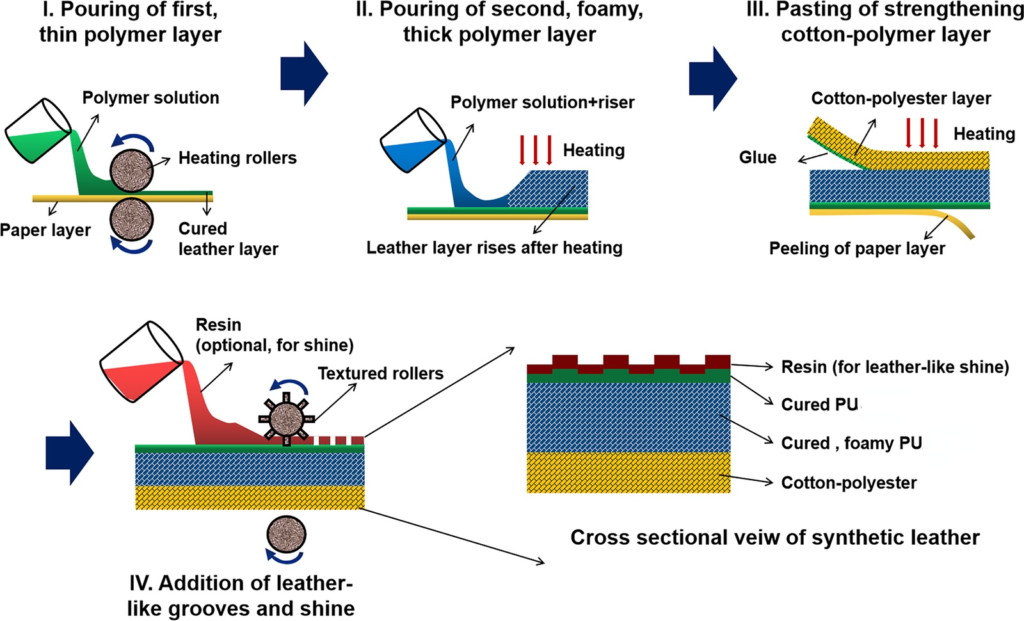

Before discussing customized PU synthetic leather, we need to understand the basic composition of PU materials. PU leather (Polyurethane Synthetic Leather) consists of three layers:

Top Layer: Usually a polyurethane coating, used to show the appearance color, leather texture, feel and functional performance.

Middle layer (PU foam layer): Provides softness and thickness for the whole.

Tecido de suporte: Determines the mechanical properties of PU leather, such as tensile strength, tear strength and ductility.

Common PU synthetic leather is divided into dry PU, wet PU and semi-PU according to the coating structure. Among them, dry PU tends to be thin, smooth, and highly simulated textured; wet PU is softer and has better coverage; and semi-PU is mainly used in cost-sensitive markets, with certain coating and PU effects but thinner thickness.

According to the application scenario, it can also be divided into:

- PU leather for shoes (requires high tear strength and flex resistance)

- PU leather for luggage (emphasizes leather texture and color performance)

- PU leather for furniture (requires flame retardancy, wear resistance, and stain resistance)

- PU leather for automobiles (emphasizes environmental protection, aging resistance, and VOC-free)

Understanding these structures and categories will help buyers customize more accurately according to product attributes.

What are the core parameters that determine the customization of PU synthetic leather?

A high-quality PU synthetic leather suitable for a specific purpose usually involves a comprehensive matching of multiple parameters. These parameters are both the key nodes of customization and the core of cost and quality control:

- Thickness: Usually ranging from 0.3mm to 2.0mm, and different industries have strict requirements on thickness. For example: sofa leather recommends more than 1.0mm; handbag leather is most commonly 0.8mm and 1.2mm.

- Color: Supports Pantone color customization, and can be multi-color embossing, spraying or water dyeing.

- Types of leather grain: cowhide, litchi, nappa, crocodile, carbon fiber, smooth flat grain, etc.

- Feel: dry, soft, smooth, heavy, etc., which can be achieved through different foaming ratios and coating adjustments.

- Environmental standards: REACH, RoHS, CA65, EN71, phthalate-free, DMF-free, etc.

- Physical properties: abrasion resistance, tear resistance, folding resistance, aging resistance, etc., need to pass standard tests such as ASTM or ISO report certification.

- Functional requirements: waterproof, flame retardant, UV resistance, mildew and antibacterial, breathable, etc.

Before determining these parameters, it is recommended to use the following professional tools:

- Hand feel tester, coating tester, Taber wear tester, ROHS tester, etc.

- Software management color library, such as Pantone Color Manager or Datacolor tools, for digital color matching and tracking.

Customization process: Turn your ideas into reality

A standard and mature PU leather customization process usually includes the following stages:

Demand communication and solution design

Customers submit samples or parameter requirements, and Yudeng’s sales and R&D team will assist in confirming core specifications such as thickness, color, leather grain, and purpose, and provide physical property suggestions when necessary.

Proofing and sample confirmation

According to design requirements, use existing or newly developed molds to make samples.

Physical property testing and certification

All proofing samples must be tested for physical properties by internal laboratories or third-party testing agencies to ensure that they meet indicators such as tensile strength, wear resistance, flame retardancy, and environmental protection.

Scheduling and material preparation for large-scale production

After the sample is confirmed, batch production is arranged according to the order quantity to control the consistency of coating thickness and foaming ratio.

Quality inspection and delivery

Yudeng has complete IQC, IPQC and FQC processes to ensure that each batch of products meets the customization standards and cooperates with customer sampling or full inspection requirements.

How to make surface treatment and special performance customization more outstanding?

The appearance and function of PU synthetic leather are not only determined by the basic structure, but also significantly affected by the post-processing process. The following are common customized processing methods:

Embossed processing: Use steel plate, silicone plate or 3D relief plate to achieve specific textures through high temperature and high pressure. Yudeng has more than 50 standard pattern plates, and can also support customers to open molds to customize exclusive textures.

Spraying process: used to change color brightness, increase anti-fouling, and smoothness, commonly used in furniture leather and clothing leather.

Lamination and coating: For example, TPU lamination can improve wear resistance and hydrolysis resistance; adding silicon coating can enhance scratch resistance and anti-aging.

Digital transfer and printing: widely used in customized pattern or brand logo output.

In addition, special additives such as UV inhibitors, mildew inhibitors, silver ion antibacterial agents, etc. can be added to give PU leather additional practicality.

Leather texture can be customized: a concerto of touch and vision

Texture is not only a matter of beauty, but also an important symbol of function and product identification. A high-quality leather grain customization usually starts from three dimensions:

Texture type selection: Select the texture according to the application scenario, such as fine Nappa grain is recommended for automobiles, large-grain lychee grain is recommended for home use, and carbon fiber grain or high-gloss surface is recommended for electronic packaging.

Mold development: If the customer has a unique texture requirement, Yudeng supports independent mold opening (sample or texture map is required).

Visual and hand feeling matching adjustment: The same texture will have different effects under different coatings and foaming states, and multiple rounds of fine-tuning are required during the proofing stage.

The coordination of texture, color, thickness and hand feeling is the real customized material.

A variety of PU leather backing substrates for you to choose

The performance of PU leather fundamentally depends on the backing fabric. Yudeng provides a variety of base fabric options to meet different strength, durability and sustainability requirements:

Polyester Knit: soft and ductile, suitable for soft bags, handbags and other fields.

Nonwoven: low cost and lightweight, suitable for bags and insoles.

Polyester cotton cloth (TC cloth): takes into account flexibility and tension, suitable for mid-to-high-end applications such as furniture and car decoration.

Microfiber cloth (Microfiber): high strength, high simulation, wear resistance, is the first choice for high-end PU leather.

Environmentally friendly base cloth (RPET, bamboo fiber, etc.): meets the demand for green products and is suitable for sustainable development projects.

The choice of substrate needs to be balanced according to the purpose and budget. For example, electronic product packaging tends to use microfiber and high-elastic composite cloth, while disposable products can use simplified non-woven base.

What are the pitfalls in the process of customizing PU synthetic leather?

Even experienced purchasers often encounter problems in the process of customizing PU synthetic leather. The following are five common “pitfalls” and corresponding suggestions summarized by Yudeng:

Failure to clarify the final use leads to material selection errors

→ Be sure to explain the use scenario, whether environmental protection, flame retardant or weather resistance and other performance requirements are required.

Only look at the appearance of the sample and ignore the physical properties

→ Require suppliers to provide test reports, such as tension, wear resistance, VOC and other data

Blindly pursue ultra-low prices and ignore quality fluctuations

→ Price is proportional to quality. Low prices may bring about problems such as thickness deviation, color difference, and batch instability.

Ignore the color difference control between proofing and batch

→ The color difference range must be clarified (generally within ±0.5 levels) and a color plate numbering system must be established.

Failure to arrange the production cycle in advance leads to delivery delays

→ Most customizations require a delivery cycle of 15 to 30 days, and production plans must be communicated with the factory in advance.

By avoiding these traps, companies can save costs, shorten cycles, and ensure stable quality in the process of customizing PU leather.

| Comece seu pedido | E-mail: hello@fjyudeng.com | Número: +86 17746077007 |