Оглавление

- What is a Wet-Laying Production Line?

- Yudeng’s Unique Advantages of Wet-laid Production Lines

- Analysis of the Main Process Flow of a Wet-laid Production Line

- Key Equipment and Technologies in Wet Processing

- Wet-processing improves the performance of Pu leather for balls

- Common problems and solutions in wet-processing

What is a Wet-Laying Production Line?

In the field of PU leather manufacturing, the wet-laying production line is a critical step. It not only determines the appearance and texture of the finished leather, but also directly affects its durability and lifespan. Simply put, the wet-laying process is a process that produces synthetic leather through a process of “coating + impregnation + curing + drying.” Compared to the dry-laying process, it places greater emphasis on the stability of the leather’s internal structure and the consistency of its surface finish.

Many people ask: What is the difference between the wet-laying and dry-laying processes? If the dry-laying process is like “brushing a layer of paint on the surface of a base fabric,” the wet-laying process is like “immersing the base fabric in a liquid environment for thorough penetration and then curing.” This method ensures that the polyurethane slurry adheres more evenly to the fibers of the base fabric, resulting in leather that is both flexible and wear-resistant.

For ball sports (such as footballs, basketballs, and volleyballs), the wet-laying process is particularly important. These require leather that is both tough and has a good balance of feel and elasticity. For example, a soccer ball’s surface must be durable and abrasion-resistant while maintaining good rebound performance; a basketball’s surface emphasizes grip and slip resistance. The wet-laid process can precisely meet these diverse performance requirements through adjustments to the formula and process, making it the preferred manufacturing method for PU leather for balls.

Yudeng’s Unique Advantages of Wet-laid Production Lines

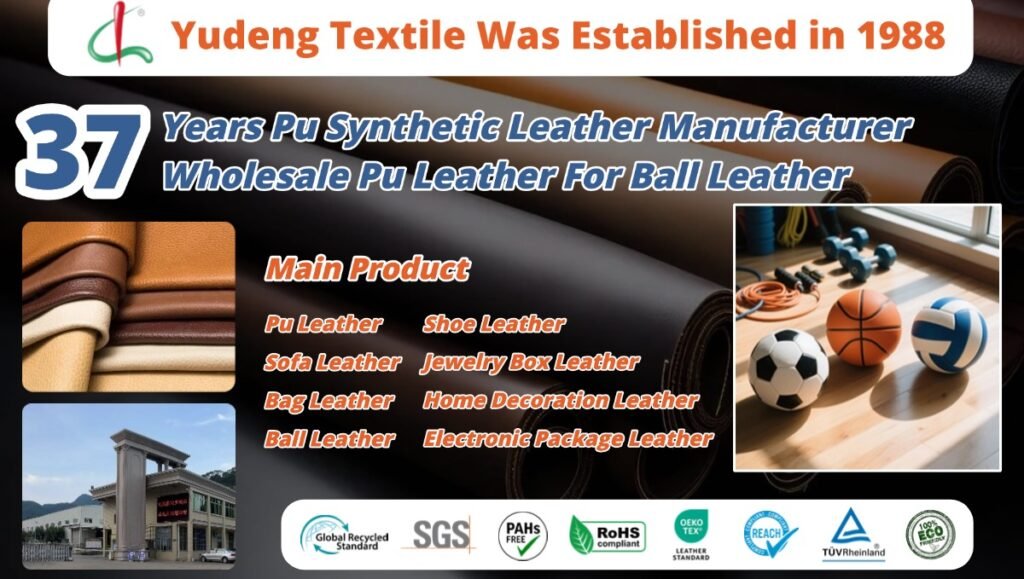

As an industry-leading производитель искусственной кожи, Yudeng possesses distinct competitive advantages in wet-laid production lines:

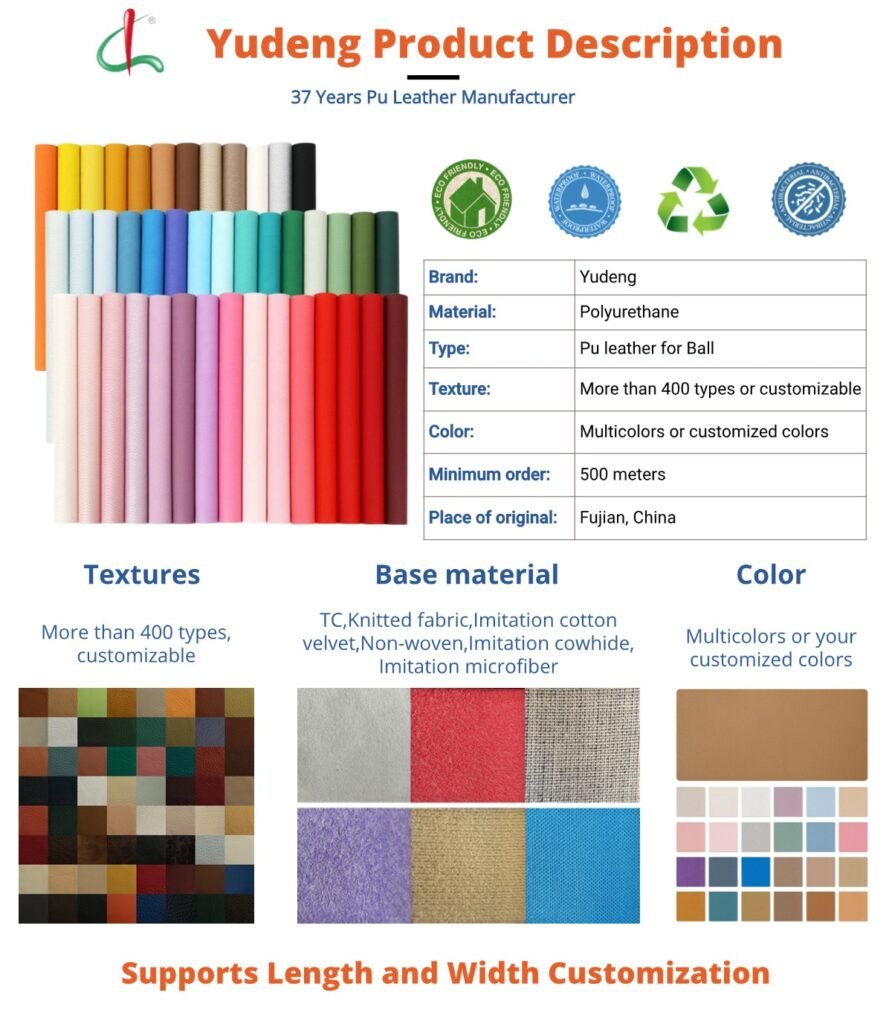

Strict Raw Material Control and Environmental Certifications: All raw materials are certified by REACH, ROHS, and OEKO-TEX®, ensuring safety and environmental friendliness.

Diverse Pattern and Color Customization: Yudeng offers over 400 embossed patterns, allowing customers to create unique brand-specific surface effects.

Highly Efficient and Consistent Production Capacity: A single production line can produce up to 100,000 meters per day, with extremely high batch-to-batch consistency.

OEM/ODM Customization Services: Yudeng provides a one-stop solution for everything from pattern design and color matching to thickness selection.

Experience in Collaborating with Global Ball Brands: Yudeng has partnered with many internationally renowned sports brands, exporting its products to Europe, South America, and Southeast Asia.

Analysis of the Main Process Flow of a Wet-laid Production Line

A complete wet-laid production line often consists of multiple linked steps. Each step may appear independent, but they are closely linked. Any overlooked detail can impact the quality of the final product. Let’s break it down one by one:

Coating and Impregnation Process

The first step is to apply a polyurethane slurry to the surface of the base fabric. The slurry is then placed in an impregnation tank to fully penetrate the base fabric fibers. Controlling the viscosity and uniformity of the slurry is crucial in this process. If the slurry is too thin, voids will form; if it is too thick, it will not penetrate fully. Yudeng’s process team adjusts the formula according to the requirements of different ball types to ensure a consistent coating thickness.

Base Fabric Selection and Processing

The base fabric is the “skeleton” of the leather and directly affects the strength and ductility of the finished product. Common base fabrics include non-woven fabrics, knitted fabrics, and warp knitted fabrics. For high-impact sports balls like basketballs, Yudeng often uses high-strength warp-knitted fabric as the base fabric; for soccer balls, it prefers lightweight non-woven fabric. Before production, the base fabric undergoes surface cleaning and tensioning to ensure a stronger coating.

Polyurethane Slurry Preparation and Coating

The slurry formulation is the heart of the wet process. It typically consists of polyurethane resin, DMF (N,N-dimethylformamide), pigments, and additives. Yudeng has extensive experience in slurry preparation, for example, by adjusting the pigment ratio and additive types to achieve varying yellowing resistance, hydrolysis resistance, and environmental performance. Coating requires precise thickness control, otherwise the ball’s surface will be uneven and its lifespan will be shortened.

Curing and Drying

The coated base fabric enters a curing tunnel, where solvents such as DMF are gradually washed away while the slurry begins to solidify into a film. It then enters a drying oven to further remove residual solvents. This step is not only environmentally friendly but also determines the safety and stability of the finished product. Yudeng uses energy-saving drying equipment that efficiently recovers solvents, reducing environmental emissions.

Surface Treatment and Embossing

The surface effects of leather are often achieved through embossing. The grainy texture of a soccer ball and the embossed stripes of a basketball are all achieved during this process. Embossing is not only aesthetically pleasing but also directly impacts the user experience. Yudeng boasts several sets of imported embossing rollers that can simulate different natural leather textures and provide customized products based on customer needs.

Product Inspection and Cutting

After production, the finished leather undergoes multiple tests, including tensile strength, abrasion resistance, hydrolysis resistance, and peel strength. Qualified products are cut into sizes suitable for ball panels and then sent to the customer’s subsequent factory for sewing and assembly.

Key Equipment and Technologies in Wet Processing

Wet process production relies on sophisticated equipment and advanced technical support. Yudeng’s завод синтетической кожи has introduced several internationally advanced wet process production lines, equipped with a range of high-end equipment:

High-Precision Coating Machine

The precision of this equipment determines the uniformity of the coating. Yudeng’s coating machine can control the thickness within ±0.02mm, ensuring consistency across each batch of leather.

Dipping Tanks and Drying Tunnel

The dipping tank design must ensure slurry fluidity and permeability, avoiding bubbles and interlayers. The drying tunnel requires multi-stage temperature control to prevent leather warping due to large temperature differences.

Environmentally Friendly Solvent Recovery System

DMF solvent is commonly used in wet processes, and direct discharge can pollute the environment. Yudeng’s production line is equipped with an advanced DMF recovery tower, achieving a recovery rate of over 95%, complying with European and US environmental regulations.

Embossing and Surface Treatment Equipment

To meet the diverse aesthetic requirements of ball brands, Yudeng has equipped itself with a variety of embossing rollers, UV coating machines, and thermal transfer equipment. This allows the production of leather with various finishes, including high gloss, matte, and pearlescent.

Intelligent Inspection and Automated Control

Modern production lines are inseparable from automation. Yudeng’s production line is equipped with an intelligent tension control system and online inspection devices, enabling real-time monitoring of thickness, color variation, and surface defects, significantly improving product stability.

Wet-processing improves the performance of Pu leather for balls

The wet-process is more than just a manufacturing method; it’s a key way to enhance leather performance.

Enhanced abrasion and scratch resistance: The deeply penetrating coating structure ensures the leather remains resistant to damage even under prolonged friction. This is particularly important for balls with frequent contact with the ground, such as footballs and basketballs.

Resilience and flexibility: The wet-processing process creates a tighter internal structure for the leather, balancing hardness and flexibility, ensuring stable elasticity for the ball.

Breathability and comfort: Wet-processed leather develops a microporous structure during curing, which helps maintain good breathability and prevents deformation during use due to overheating.

Improved surface feel and visual quality: The wet-processed embossing creates a clear, realistic texture that simulates the feel of natural leather while maintaining color stability.

Improved lifespan and environmental performance: Thanks to hydrolysis-resistant and anti-yellowing treatments, wet-processed leather has a longer outdoor lifespan and is more environmentally friendly.

Common problems and solutions in wet-processing

Even mature processes can encounter various problems. Yudeng summarized the following common problems and provided solutions:

Bubbles and surface defects: These are often caused by uneven slurry mixing or improper coating speed. The solution is to optimize the slurry ratio and adjust the coating machine speed.

Uneven coating thickness: This is often related to tension control and base fabric flatness. This can be addressed through intelligent tension control systems and pretreatment processes.

Hydrolysis and yellowing resistance: Adding specialized additives to the slurry or using polymer stabilizers can significantly extend the life of the leather.

Difficulty in cutting finished products: This can be achieved by improving the bonding strength between the leather layers to prevent delamination, while also using laser cutting equipment to improve precision.

| Оформить заказ | Email: hello@fjyudeng.com | Номер: +86 17746077007 |