Tabla de contenido

- Comprensión del cuero PU: materiales, tipos y aplicaciones

- Precio del cuero sintético en Pakistán: factores influyentes y perspectivas del mercado

- Ventajas del proceso de fabricación de cuero PU y personalización profesional

- Garantía de calidad y certificaciones

- Capacidades industriales de Yudeng y ventajas de colaboración con el cliente

Comprensión del cuero PU: materiales, tipos y aplicaciones

El cuero sintético de poliuretano (PU) es uno de los materiales de cuero artificial más utilizados en muebles, calzado, interiores de automóviles y productos de moda modernos. En Pakistán, Yudeng es una de las empresas líderes. Fabricantes de cuero sintético en PakistánConocida por su amplia experiencia y profesionalismo. En comparación con el cuero genuino, el cuero PU es ligero, impermeable, resistente al desgaste y ecológico. La demanda de cuero PU en el mercado de gama media y alta de Pakistán sigue creciendo, y Yudeng se ha convertido en una opción predilecta para los compradores que buscan la calidad.

1. Composición del material

- resina de poliuretano (PU):Proporciona suavidad, brillo, textura realista y resistencia al desgaste.

- Tejidos de base:Proporciona soporte estructural y durabilidad, comúnmente incluye telas de punto, tela Oxford, telas no tejidas y telas reforzadas con PVC.

- Diferentes materiales base se adaptan a diferentes aplicaciones, por ejemplo, los muebles requieren grosor y durabilidad, mientras que el calzado y los bolsos requieren flexibilidad y forma.

2. Tipos de superficie

- Texturas de piel sintética:Imita de cerca las texturas del cuero natural, adecuado para muebles, bolsos y asientos de automóviles.

- Texturas en relieve:Prensado mecánicamente para crear patrones únicos, ampliamente utilizado en calzado y artículos decorativos.

- Superficies brillantes y mateLas superficies brillantes son adecuadas para bolsos y prendas de vestir, las superficies mate son ideales para revestimientos de muebles y partes superiores de zapatos, mejorando el tacto y el atractivo visual.

3. Áreas de aplicación

- Muebles y decoración del hogar:Sofás, fundas de sillas, cojines, etc.

- Calzado y bolsos:Parte superior del calzado resistente al desgaste y materiales de primera calidad para bolsos.

- Interiores de automóviles y aeroespaciales:Fundas de asientos, paneles de puertas, salpicaderos.

- Otras áreas:Dispositivos médicos, instalaciones de juegos infantiles y equipamiento deportivo.

Precio del cuero sintético en Pakistán: factores influyentes y perspectivas del mercado

El Precio del cuero PU en Pakistán Se ve influenciado por múltiples factores. Comprender estos factores es crucial para que las empresas tomen decisiones de compra informadas y controlen sus costos. Los principales factores y perspectivas del mercado son los siguientes:

1. Costos de la materia prima

- Precio de la resina de PU: fluctúa con el mercado internacional de materias primas químicas, lo que afecta directamente el precio final del cuero de PU.

- Costos de la tela base: Dependen del tipo de material, el grosor y los canales de suministro; las diferencias en los materiales base generan variaciones significativas de precios.

- Calidad del material: La resina de alta calidad y los tejidos base mejoran el rendimiento del producto, pero son relativamente más caros.

2. Proceso de producción y complejidad de la textura

- Grosor y capas: El cuero PU más grueso o multicapa consume más material y requiere más procesamiento, lo que aumenta los costos.

- Gofrado y acabados especiales: Texturas complejas, gofrados o tratamientos de superficie (brillo, mate, impermeable) requieren tiempo de procesamiento y equipamiento adicional.

- Nivel de automatización: Las líneas de producción altamente automatizadas aumentan la eficiencia, pero la inversión en equipos afecta el precio del producto.

3. Demanda y oferta del mercado

- El mercado de gama media y alta en Pakistán mantiene una demanda constante de cuero PU, especialmente en muebles, interiores de automóviles y bolsos.

- Número de proveedores y competencia: Los precios aumentan cuando la oferta es escasa y tienden a estabilizarse en un mercado competitivo.

- Costes estacionales y logísticos: Los periodos de máxima demanda y los costes de envío también influyen en el precio final.

Ventajas del proceso de fabricación de cuero PU y personalización profesional

La principal competitividad de Yudeng reside en su excelente proceso de fabricación y su completa capacidad de personalización. Desde la adquisición de la materia prima hasta la entrega del producto terminado, la empresa controla estrictamente cada paso para garantizar que sus productos de cuero sintético cumplan con los más altos estándares.

Selección de materia prima

Yudeng utiliza resina de poliuretano de alta calidad y una variedad de tejidos base. La resina debe ser resistente al desgaste, flexible y cumplir con las normas ambientales, mientras que el tejido base garantiza durabilidad y facilidad de procesamiento. Los clientes pueden elegir entre tejidos de punto, tela Oxford o tejidos reforzados con PVC según la aplicación, optimizando así el rendimiento del producto.

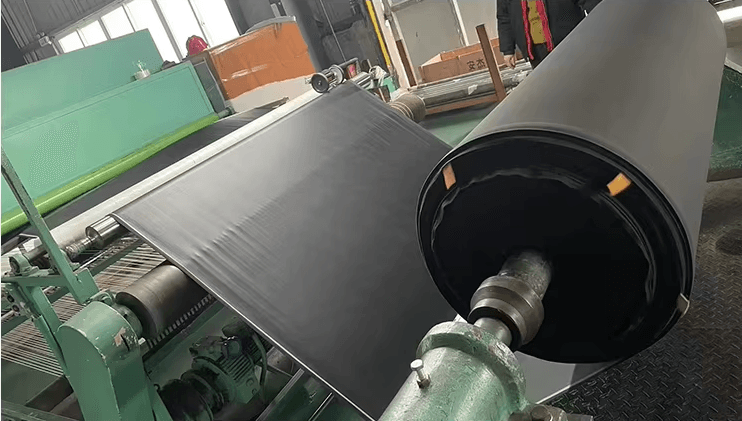

Proceso de fabricación del núcleo

El proceso de producción de cuero PU incluye:

- Recubrimiento seco/húmedo: Aplique poliuretano uniformemente sobre la tela base para crear una superficie resistente y lisa;

- Repujado: utilice máquinas de repujado de precisión para producir patrones de imitación de cuero, texturas de animales, texturas de cocodrilo, serpiente, cebra, lichi y más;

- Tratamiento de superficie: Aplicar acabados mate, brillante o impermeable para mejorar el tacto y la durabilidad;

- Inspección del producto terminado: pruebas exhaustivas de resistencia a la abrasión, resistencia al desgarro, resistencia a la luz y resistencia al agua para garantizar la calidad de fábrica.

Ventajas de la personalización profesional

Yudeng ofrece más de 400 opciones de textura, patrones de apoyo, grosor, flexibilidad y personalización del material base. Los clientes pueden responder rápidamente desde muestras de lotes pequeños hasta la producción a gran escala para satisfacer diversas necesidades de productos, como:

- Muebles de alta gama:Texturas suaves y realistas con resistencia al desgaste;

- Parte superior del calzado:Resistente al desgaste, texturas detalladas, alta formabilidad;

- Interiores de automóviles:Impermeable, resistente a la luz, excelente resistencia a la abrasión.

Además, Yudeng puede producir muestras urgentes en 2 días y completar la producción en masa en 5 días, acortando enormemente el tiempo de comercialización y mejorando la competitividad.

Garantía de calidad y certificaciones

En la industria de fabricación de cuero PU, la calidad es la clave de la competitividad. Yudeng (Yudeng Textile), con 38 años de experiencia en el sector, ha establecido un sistema integral de gestión de calidad que controla estrictamente cada etapa, desde la materia prima hasta el producto terminado, para garantizar que cada metro de cuero PU cumpla con los altos estándares del cliente.

1. Gestión de calidad de proceso completo

- Inspección de materia prima:Seleccione estrictamente la resina de PU y las telas base para garantizar la resistencia al desgaste, la suavidad y el cumplimiento ambiental para cumplir con los estándares internacionales.

- Monitoreo de producción:Gestione digitalmente el espesor del recubrimiento, la presión de estampado, la temperatura de secado y la uniformidad del recubrimiento para garantizar la estabilidad y la consistencia del lote.

- Inspección del producto terminado:Pruebe la resistencia a la abrasión, la resistencia al desgarro, la resistencia a la luz, la resistencia al agua y la diferencia de color antes del envío para garantizar el rendimiento y la apariencia.

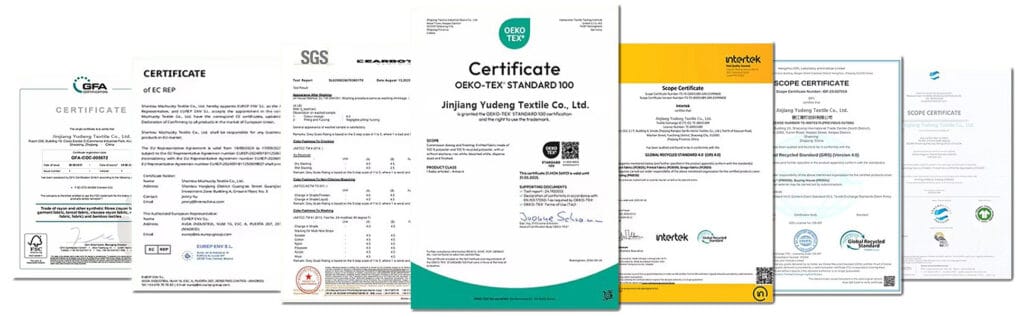

2. Certificaciones internacionales y de la industria

- Certificación del Sistema de Gestión de Calidad ISO 9001:Estandariza los procesos de producción, gestión y control de calidad.

- Certificación de Producción Sostenible GRS:Garantiza prácticas de producción sostenibles y ambientalmente responsables.

- Certificación ambiental REACH/RoHS:Cumple con las regulaciones ambientales globales.

- Certificación de la norma OEKO-TEX:Confirma que los productos están libres de químicos dañinos y son seguros.

Capacidades industriales de Yudeng y ventajas de colaboración con el cliente

Yudeng, con 38 años de experiencia en la fabricación de cuero sintético, ha consolidado capacidades excepcionales y una sólida reputación. La empresa demuestra importantes ventajas en producción, I+D y servicio al cliente:

1. Amplia experiencia en la industria

- Establecido en 1988, centrándose en la investigación y el desarrollo y la fabricación de cuero sintético PU de alta calidad, acumulando una rica experiencia.

- Puede manejar diversos materiales, texturas y espesores, garantizando altos estándares en resistencia al desgaste, suavidad y cumplimiento ambiental.

2. Fuerte capacidad de producción

- Escala de fábrica:100.000 m² de superficie, 200 empleados, equipado con 10 líneas de producción.

- Capacidad de producción:Producción diaria de hasta 150.000 metros, compatible con grandes pedidos y necesidades de producción urgentes.

- Equipos y procesos avanzados:Las líneas de producción completas en seco, húmedo y de acabado garantizan la consistencia del lote.

3. Capacidades profesionales de I+D y personalización

- Personalización de texturas:Más de 400 texturas de cuero disponibles para diseño personalizado.

- Personalización del material base:El PU se puede unir a varios sustratos para cumplir con diferentes escenarios de aplicación.

- Respuesta rápida:Muestras listas en 2 días, producción en masa en 5 días.

4. Ventajas de la colaboración con el cliente

- Pedido mínimo flexible:300 metros, apto para todo tipo de clientes.

- Aplicaciones multisectoriales:Muebles, asientos de automóviles, calzado, dispositivos médicos e instalaciones infantiles.

- Soporte de personalización:Patrones, colores, espesores y materiales base personalizados para adaptarse a los requisitos de la marca.

- Servicio confiable:Soporte técnico completo y servicio posventa desde consulta, muestras hasta entrega a gran escala.

| Inicie su pedido | Correo electrónico: hello@fjyudeng.com | Número: +86 17746077007 |

El cuero PU ocupa un lugar insustituible en el mercado moderno de gama media-alta. Yudeng (Yudeng Textile), con 38 años de experiencia profesional, equipos de producción avanzados y certificaciones de prestigio, destaca en el mercado pakistaní e internacional. La empresa no solo ofrece productos de cuero PU de alta calidad, duraderos y ecológicos, sino que también ofrece una sólida capacidad de personalización y un servicio al cliente flexible y eficiente. Ya sea para muebles, interiores de automóviles, calzado, bolsos, productos médicos o infantiles, Yudeng ofrece productos confiables y un servicio premium, generando mayor valor para los clientes. Elegir a Yudeng significa elegir un socio con calidad confiable y capacidades líderes en la industria.