With the continuous progress of modern materials science, PU synthetic leather (polyurethane synthetic leather) has gradually become an important member of the materials industry that cannot be ignored. It is not only favored by designers and consumers for its appearance and texture comparable to natural leather, but also widely used in various industrial and consumer fields because of its strong controllability, stable production and moderate cost.

PU synthetic leather has the advantages of lightness, wear resistance, and customizability, and can accurately meet the dual needs of functionality and aesthetics in different markets. Especially in the era of advocating environmental protection and sustainability around the world, it has achieved breakthroughs in environmental protection performance by relying on the continuous integration of new water-based environmental protection technology and bio-based materials, and has rapidly emerged as an ideal solution to replace genuine leather.

Yudeng will deeply analyze the definition, structure, development background and manufacturing process of PU synthetic leather, and comprehensively explore the adaptability, quality assessment points, environmental protection progress and future trends of PU leather in different application fields, aiming to provide buyers, brand designers and material R&D personnel with a detailed and practical professional guide.

Table of contents

- What is PU synthetic leather?

- Detailed explanation of the core manufacturing process of PU synthetic leather

- Comparison of PU synthetic leather: PVC, artificial leather, natural leather

- Diversified applications and functional expansion of PU leather

- How to scientifically judge the quality of PU synthetic leather?

- PU leather industry in green transformation: challenges and progress

- How to choose a high-quality PU leather supplier? Yudeng’s customized service advantages

What is PU synthetic leather?

PU synthetic leather is a high-performance synthetic material that uses polyurethane as the main coating material and is composited with a base fabric substrate through a series of processes. It combines leather texture, flexibility, and processing flexibility, and is currently one of the artificial materials that is closest to the sensory effect of natural leather.

Its basic structure includes three functional areas:

- Surface layer (PU resin layer): mainly determines the product appearance texture, color performance, surface texture and physical properties such as wear resistance and water resistance;

- Middle layer (foaming/adhesive layer): provides cushioning, softness and thickness adjustment through chemical or physical foaming methods;

- Bottom layer (base fabric layer): commonly used non-woven fabrics, knitted fabrics, woven fabrics and other materials, determine the overall stability, processability and mechanical support of the material.

PU synthetic leather was born in the 1960s as an environmentally friendly upgraded version of PVC artificial leather. Compared with PVC leather, PU synthetic leather removes harmful ingredients such as chlorides and plasticizers, and has more environmental advantages and comfort. With the evolution of polyurethane synthesis technology and equipment, PU synthetic leather continues to expand its application boundaries, gradually penetrating into multiple fields such as footwear, luggage, home furnishings, automobiles, electronics, etc., and replaces natural leather in multiple market segments to form an independent and complete industrial chain.

Detailed explanation of the core manufacturing process of PU synthetic leather

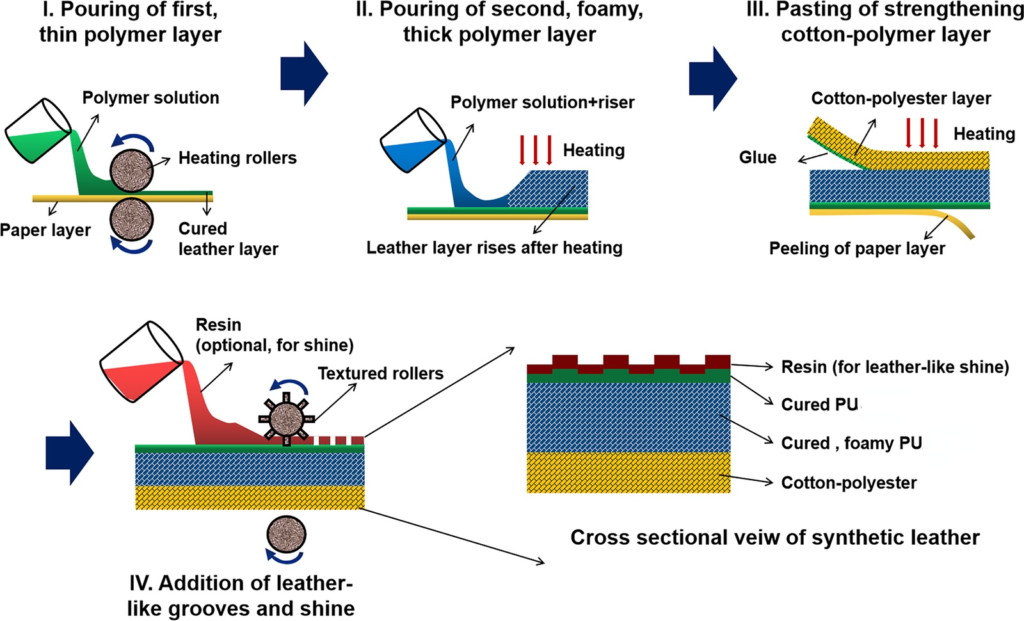

The manufacturing of PU synthetic leather relies on highly professional equipment and process control, which is mainly divided into two routes: dry PU process and wet PU process.

Dry PU process

It is mainly used to produce lightweight and exquisite PU fabrics, suitable for clothing, decoration and other fields.

- Use release paper as the substrate to evenly scrape the PU resin on the surface.

- After multiple stages of heating and drying, a continuous film is formed.

- The film and the base fabric are pressed together at high temperature to achieve a composite structure.

- After peeling off the release paper, post-finishing is performed, such as glazing, embossing, and anti-UV treatment.

The typical advantages of dry PU are: bright colors, soft texture, precise thickness control, and highly simulated surface texture.

Wet PU process

It is suitable for application scenarios with higher requirements for air permeability, wear resistance, and thickness structure, such as sports shoe uppers and automotive interiors.

- Mix PU with DMF solution and apply it on the base fabric.

- Phase separation reaction is carried out in a coagulation tank (containing aqueous solution) to form a porous structure.

- The product is shaped through drying, shaping, finishing and other processes.

The key advantage of wet PU is its good gas and moisture permeability, physical toughness and structural stability, and it is the mainstream choice for footwear and transportation cabin interiors.

Yudeng equipment features and advantages:

The automatic scraping head has millimeter-level thickness precision control to ensure consistency.

The drying tunnel partition temperature control technology improves drying efficiency and coating stability.

The finishing equipment can achieve functional finishing treatments such as waterproof, antibacterial, and fireproof to meet diversified terminal needs.

Comparison of PU synthetic leather: PVC, artificial leather, natural leather

In actual material selection, many customers will ask: “Where is PU synthetic leather better than genuine leather?” or “How different is it from PVC leather?” The following are several key comparison dimensions:

| Dimensions | PU synthetic leather | PVC leather | Natural leather |

| Touch texture | Soft and close to the skin, close to genuine leather | Slightly hard, with a plastic feel | Real leather, natural elasticity |

| Wear resistance | High wear resistance, long service life | General, easy to age | Easy to scratch, need maintenance |

| Breathability | Wet PU is better | Almost no | Excellent |

| Environmental performance | Support water-based/bio-based | Contains chlorine and plasticizers | Animal origin, non-renewable |

| Customizability | Color and texture can be adjusted widely | Surface changes are limited | Natural patterns are difficult to control |

| Cost control | Medium, stable | Low, large quality differences | High, unstable |

Data reference: PU synthetic leather accounts for more than 57% of the global synthetic leather market and is widely regarded by brand owners as the main material to replace genuine leather and PVC in the future.

Diversified applications and functional expansion of PU leather

The reason why PU synthetic leather is popular is its wide adaptability and sustainable functional expansion.

Footwear industry

Applied to uppers, heels, shoelace support structures, etc.

Wear-resistant and lightweight, suitable for sports, leisure, workwear and other styles.

Clothing and accessories

Making leather clothes, leather pants, leather skirts, hats, gloves, etc.

Soft and smooth, waterproof and windproof, suitable for fast fashion and high-end customization.

Furniture soft cover

Soft cover for sofas, office chairs, bedside backrests, etc.

Anti-fouling and antibacterial, easy to clean, suitable for commercial and home scenes.

Automobiles and vehicles

Applied to car seats, door panels, and instrument panel coverings.

Can meet RoHS/VOC standards and conform to the trend of green travel.

Digital packaging and 3C peripherals

Tablet protective cases, headphone covers, glasses cases, etc.

The surface can be processed with special functional layers such as antibacterial, anti-scratch, and anti-fingerprint.

How to scientifically judge the quality of PU synthetic leather?

In the process of material screening, quality judgment needs to take into account both visual perception and physical and chemical performance testing.

Appearance inspection:

Whether the surface is smooth and flat, and the color is consistent.

Whether there are defects such as bubbles, cracks, impurities, peeling, etc.

Physical performance testing:

Tensile strength, tear strength (>50N), abrasion resistance, folding resistance (>100,000 times), etc.

If necessary, entrust a third-party laboratory (such as SGS, TÜV) to conduct a full set of verification.

Functional testing:

UV resistance, flame retardancy, antibacterial, moisture permeability and other functional project tests.

Selection in accordance with application scenario requirements.

Environmental certification review:

REACH, RoHS, OEKO-TEX® and other environmental compliance standards.

Whether the company has established a traceability material archive management system.

PU leather industry in green transformation: challenges and progress

Traditional PU synthetic leather has been under environmental pressure due to solvent-containing processes. Nowadays, the rapid development of green materials and clean processes is driving PU leather towards a more sustainable direction.

Highlights of green transformation technology:

- Water-based PU resin technology: VOC emissions are greatly reduced, suitable for environmentally sensitive industries such as children’s clothing, automobiles, and electronic packaging.

- Application of bio-based polyurethane: derived from renewable resources such as corn starch, castor oil, etc., reducing carbon footprint.

- Closed solvent recovery system: reduce harmful emissions and improve the factory’s ESG score.

Yudeng’s environmental layout:

- Fully promote the application of water-based systems, and the main products do not contain DMF.

- Introduce multiple reuse treatment systems to achieve wastewater and waste gas recycling.

- Products are 100% compliant with EU REACH and RoHS certifications, supporting customers to pass global market regulatory reviews.

How to choose a high-quality PU leather supplier? Yudeng’s customized service advantages

When faced with a large number of supply options, customers should focus on the following five dimensions:

Production line capacity and automation level: whether there is a dry and wet parallel production system to meet different order requirements.

- R&D and proofing responsiveness: Can customized textures, colors and performance combinations be developed quickly according to customer usage?

- Quality control process: Is it equipped with professional laboratories, raw material inspection, and online monitoring systems?

- Certification and traceability: Is a complete material traceability and compliance document system established?

- International service capabilities: Is there multilingual customer service and international market shipping experience?

Yudeng provides:

- 5 dry processing production lines, 3 wet processing production lines, and 2 finishing production lines, with a daily production capacity of more than 150,000 square meters.

- One-stop OEM/ODM service from proofing, color matching, mold development to customized finishes.

- Global responsive service team, covering major markets such as Europe, America, Asia Pacific, and the Middle East.

- Strict quality control and environmental compliance dual standards support brand customers to pass large-scale terminal audits.

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

In the future, PU synthetic leather will not only replace the role of genuine leather, but will also assume the heavy responsibility of multi-function, high performance and environmental responsibility in technological progress. With the continuous integration of multifunctional coatings, digital texture simulation, intelligent manufacturing and recycling mechanisms, it will reshape the perception and expectations of materials in the high-end manufacturing industry.

For brands, choosing partners such as Yudeng PU leather manufacturer with independent R&D capabilities, green supply chain integration capabilities and international service experience will undoubtedly give them a forward-looking advantage in global competition.

If you need free samples, application recommendations or OEM/ODM services, please contact Yudeng customization consultants to start your journey of synthetic material innovation.