Table of contents

- Yudeng: Company as a China PU Synthetic Leather Customization Specialist

- Yudeng’s PU Synthetic Leather Manufacturing Experience and Factory Capabilities

- Yudeng’s Core Competitiveness: PU Leather Customization Capability

- Main PU Synthetic Leather Product Types and Performance Characteristics

- Quality Management System and PU Synthetic Leather Testing Standards

Yudeng: Company as a China PU Synthetic Leather Customization Specialist

Against the backdrop of a highly mature synthetic leather industry in China, companies with long-term competitiveness are often not those with the widest product lines, but those that focus deeply on a single material category and continuously accumulate manufacturing expertise. Yudeng is precisely such a manufacturer, with high-quality PU synthetic leather customization as its core direction.

- Establishment and Experience Accumulation: Founded in 1988, Yudeng has specialized in the research, development, and manufacturing of polyurethane PU synthetic leather for 38 years. Through long-term practice, the company has established a stable and mature production and quality control system.

- Clear Product and Market Positioning: Yudeng consistently focuses on a single PU synthetic leather material system rather than pursuing multi-material expansion. This focus enables a higher level of professionalism in formulation, process control, and texture management.

- Role and Value Within the Industry: Within the China pu leather company landscape, Yudeng is positioned as a supplier that delivers stable, customizable, and long-term repeatable PU leather solutions for mid- to high-end applications.

- Primary Application Markets Served: Yudeng’s products are widely used in footwear, bags, furniture, automotive interiors, yachts and marine applications, and functional protection fields, where material consistency and durability are critical.

Yudeng’s PU Synthetic Leather Manufacturing Experience and Factory Capabilities

For a professional PU leather supplier, manufacturing experience is reflected not only in years of operation, but also in the ability to control process details and production stability. Thirty-eight years of continuous focus on PU materials have given Yudeng clear advantages in production management and technical accumulation.

- Factory Scale and Workforce: Yudeng’s manufacturing facility covers approximately 100,000 square meters and employs around 200 staff members, supported by a well-structured production and management team.

- Production Line Structure and Process Completeness: The factory operates a total of 10 production lines, including 5 dry-process lines, 3 wet-process lines, and 2 post-finishing lines. This configuration allows flexible process selection based on different product requirements.

- Stable Production Capacity and Delivery Capability: Daily output can reach up to 150,000 meters. While ensuring scale production, Yudeng maintains strict consistency control between different batches.

- Practical Impact of Experience on Quality: Long-term manufacturing experience enables Yudeng to continuously optimize key details such as coating uniformity, foaming density, and post-finishing stability, effectively reducing risks during end use.

Yudeng’s Core Competitiveness: PU Leather Customization Capability

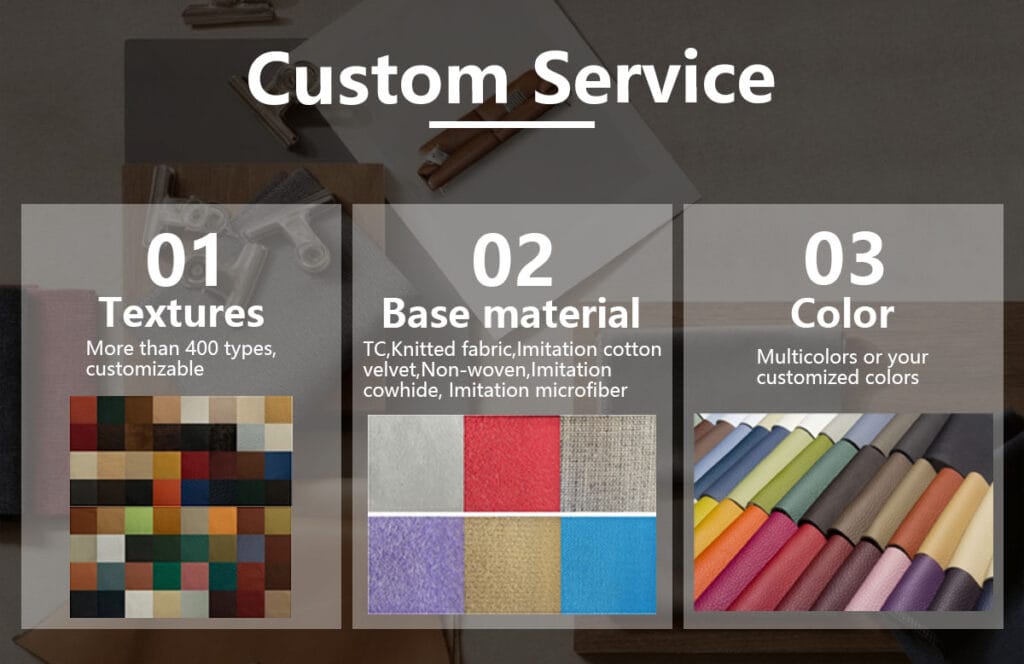

In today’s PU synthetic leather market, customization capability has become a key indicator of supplier professionalism. Yudeng has developed a systematic advantage in texture, thickness, substrate selection, and functional performance.

- Extensive and Mature Texture Library: Yudeng offers more than 400 proven leather textures, including animal grain, crocodile, snake, ostrich, zebra, lychee, sheepskin, bark, woven patterns, mirror finishes, and more.

- Texture and Thickness Customization: Texture depth, three-dimensional effect, clarity, surface gloss, and material thickness can all be adjusted according to customer requirements, ensuring precise alignment with the final application.

- Substrate Selection and Functional Design: Customization is supported across various fabric backings, blended materials, and special substrates, enabling PU leather to meet specific demands for abrasion resistance, elasticity, comfort, and protective performance.

- Color and Surface Effect Customization: Multiple color solutions are available, including gloss, matte, metallic, and gradient effects. Additional processes such as partial printing, hot stamping, or special surface treatments can be applied to support brand differentiation.

- Size and Cutting Specification Customization: Yudeng can tailor roll width, length, and material formats based on customer product specifications, ensuring efficient downstream processing and improved material utilization.

- Brand Value of Customization: Stable and repeatable customization solutions help brands build clear product recognition and are commonly adopted by mid- to high-end brands as a long-term material strategy.

Main PU Synthetic Leather Product Types and Performance Characteristics

Yudeng develops a diverse range of PU synthetic leather products tailored to different application scenarios, covering footwear, bags, furniture, home decoration, electronic packaging, and gift packaging, with performance optimized for each use environment.

Main Product Categories Include:

- Shoe Leather: Designed for flex resistance, abrasion resistance, and appearance stability, suitable for sports shoes, casual footwear, and functional shoe models.

- Bag Leather: Emphasizes surface texture, color consistency, and processing adaptability, supporting large-scale production of bags and leather goods.

- Sofa Leather: Focuses on scratch resistance, aging resistance, and long-term comfort, ideal for sofas and seating applications.

- Ball Leather: Balances elasticity, wear resistance, and impact resistance for various sports balls.

- Jewelry Box Leather: Highlights refined texture and premium appearance for jewelry boxes and gift packaging.

- Home Decoration Leather: Applied in wall panels, upholstery, and furniture accessories, combining visual appeal with durability.

- Electronic Package Leather: Prioritizes flexibility, abrasion resistance, and lightweight protection for electronic products.

Performance Characteristics:

Yudeng’s PU synthetic leather demonstrates stable structural performance and consistent surface treatment, minimizing batch-to-batch variation. The materials provide uniform appearance, comfortable hand feel, and compatibility with various post-processing techniques. At the same time, a well-balanced approach between durability and cost efficiency allows customers to achieve both quality performance and economic viability.

Quality Management System and PU Synthetic Leather Testing Standards

Consistent output of high-quality PU synthetic leather relies on a systematic quality management framework. Yudeng integrates quality control throughout the entire production cycle, supported by standardized operations and detailed records at each stage.

Raw Material Inspection

- Evaluation of supplier qualifications and raw material performance prior to procurement

- Strict physical and chemical testing for each incoming batch

- Complete documentation and traceability to ensure material safety and reliability

Production Process Control

- Multiple inspection checkpoints at key processes such as coating thickness, foaming uniformity, and backing adhesion

- Standardized process parameters to maintain batch consistency

- Real-time monitoring of equipment conditions and environmental factors to reduce production fluctuations

Finished Product Inspection and Performance Testing

- Visual inspection for texture clarity, surface defects, and color deviation

- Functional testing including abrasion resistance, resilience, weather resistance, and water resistance

- Regular sampling with recorded results to provide verifiable performance data

Environmental Compliance and Certification Management

- Certified under ISO 9001 quality management system

- Compliance with REACH, RoHS, and OEKO-TEX® international environmental standards

- GRS certification to ensure sustainable and traceable production processes

| Start Your order | Email: hello@fjyudeng.com | Number:+86 17746077007 |

With 38 years of continuous focus on PU synthetic leather manufacturing, Yudeng has built a solid reputation as a professional and reliable pu leather company. Through stable production systems, comprehensive customization capabilities, and strict quality control, Yudeng consistently delivers PU leather solutions suited for long-term, real-world applications.

For brands and manufacturers seeking a dependable pu leather supplier with proven experience and consistent quality, Yudeng offers a manufacturing partnership grounded in expertise, stability, and trust.