Table of contents

Overview of Pu Leather Processing

In the modern synthetic leather industry, Pu leather (polyurethane synthetic leather) is the most widely used material. Not only does it resemble natural leather in appearance and feel, it also offers advantages such as affordability, versatility, and stable performance. Consequently, it is widely used in a variety of applications, including sports shoes, bags, balls, furniture upholstery, and automotive interiors.

To understand the differences in quality and performance of Pu leather, it’s important to understand its processing methods. Currently, the two most popular processing methods in the industry are dry and wet. These two processes go beyond a simple distinction between “dry” and “wet”; rather, they encompass comprehensive differences in coating methods, molding principles, equipment used, and final product performance.

Dry processing: A solvent-based or solvent-free polyurethane resin is directly applied to the base fabric surface. The solvent evaporates through hot air drying, forming a leather film.

The wet process involves immersing the base fabric and coating in a coagulating solution after resin coating. The resin precipitates upon contact with water, forming a film. This film is then washed and dried, resulting in a finer, more breathable leather layer.

These two methods each have their own unique characteristics, which directly determine the intended use of the final product. For example, dry-process Pu leather is more suitable for applications seeking diverse appearances and production efficiency, while wet-process Pu leather offers superior breathability and durability.

Detailed Explanation of Pu Leather Dry Processing

Basic Principles of Dry Processing

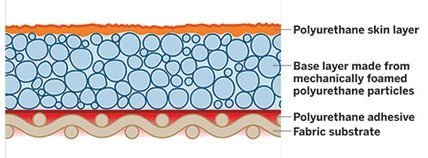

The core of the dry process lies in “direct coating and drying.” During production, the polyurethane resin is prepared into a slurry of a specific viscosity and evenly applied to the base fabric. Heating then rapidly evaporates the solvent, ultimately forming a durable film. This film not only provides protection but also imparts a rich surface texture to the Pu leather.

Because the dry process is relatively straightforward and eliminates the need for multiple soaking and washing steps required by the wet process, it offers shorter production cycles and lower energy consumption.

Main Steps in Dry Processing

Base Fabric Preparation: Common base fabrics include non-woven fabrics, knitted fabrics, and woven fabrics. They require cleaning and shaping to ensure a smooth surface.

Coating: A coater is used to evenly apply the resin slurry to the base fabric surface. Coating methods include knife coating and roller coating, which vary in surface smoothness and thickness.

Drying: The base fabric enters a hot air drying oven, where the solvent gradually evaporates, forming a solidified polyurethane film.

Surface Treatment: Embossing, dyeing, printing, and gloss treatments can be performed to enhance the decorative and functional properties of the surface according to customer requirements.

Shaping and Finishing: Hot pressing, cold pressing, and the application of functional coatings further enhance properties such as wear resistance, water resistance, and weather resistance.

Common Equipment and Tools for Dry Processing

- Coating Machine: Used to control coating thickness and uniformity, it is a key piece of equipment in the dry process.

- Hot Air Drying Oven: Uses high-temperature hot air to completely evaporate the solvent.

- Embossing machines: Used to create textures such as lychee and nubuck.

- Finishing equipment: Includes polishing machines and transfer machines for enhanced decorative effects.

Advantages and Disadvantages of the Dry Process

Advantages

- High production efficiency, suitable for large-scale production.

- Diverse surface treatments, highly decorative.

- Finished product thickness is stable, with excellent surface flatness.

- Relatively simple equipment, lower investment cost than wet process.

Disadvantages

- Poor breathability, prone to feeling stuffy when worn.

- Not as soft as wet process leather.

- Environmental pressure is high, and solvent-based processes can emit VOCs.

Actual Applications

Dry process Pu leather is commonly used in sports shoe uppers, casual shoe linings, luggage materials, and furniture upholstery. For example, many brightly colored women’s bags with intricate embossing patterns are produced using the dry process to ensure a striking appearance.

Detailed Explanation of the Wet Processing of Pu Leather

Basic Principles of Wet Processing

The unique feature of the wet process is its “coagulation and film formation in water.” A resin slurry is first applied to a base fabric, then placed in a water tank containing a coagulant. The resin precipitates upon contact with water, forming a porous leather film. This microporous structure gives wet-processed Pu leather superior breathability and softness.

Main Steps of Wet Processing

- Base Fabric Preparation: Similar to the dry process, pretreatment is required to ensure a clean and smooth surface.

- Coating: The resin slurry is evenly applied to the base fabric using a coating machine.

- Immersion Coagulation: The base fabric with the resin layer enters the coagulation tank, where the solvent in the resin reacts with water to precipitate polyurethane and form a film.

- Cleaning: Residual solvents and byproducts are removed to ensure environmental and health benefits.

- Drying: Drying is performed using vacuum or hot air equipment to form a stable film.

- Surface Treatment and Finishing: Dyeing, spray coating, waterproofing, and antibacterial finishing are available.

Commonly Used Equipment for Wet Processing

- Coagulation Tank: Determines pore size and distribution, affecting breathability.

- Cleaning Equipment: Ensures environmental friendliness and reduces harmful residues.

- Vacuum Dryer: Maintains softness while preventing excessive shrinkage in the finished product.

- Surface Treatment Equipment: Enhances appearance and functionality.

Advantages and Disadvantages of Wet Processing

Advantages

- Excellent breathability, suitable for applications involving skin contact.

- Excellent softness, with a feel similar to genuine leather.

- High abrasion resistance, suitable for products subjected to high-intensity use.

- Stable structure, with superior folding resistance compared to dry processing.

Disadvantages

- Complex process, long production cycle.

- High equipment investment, large floor space required.

- High water consumption, requiring strict environmental protection treatment.

Practical Applications

Wet-processed Pu leather is widely used in footballs, basketballs, breathable sports shoes, functional luggage, and more. For example, international standard footballs are mostly made of wet-processed leather, which maintains excellent performance despite intense friction and the humidity of the pitch.

Comparative Analysis of Dry and Wet Processes

When choosing a Pu leather processing method, choosing between dry and wet processes isn’t simply a matter of “which is better”; rather, it requires a comprehensive assessment based on cost, performance, application scenarios, and environmental requirements. Below, we compare these processes from several perspectives.

Cost Comparison

Equipment Investment: Dry process production lines require relatively simple equipment, generally requiring only a coater and drying oven, resulting in a relatively low initial investment. Wet processes, on the other hand, require a coagulation tank, a circulating water system, and vacuum drying equipment, resulting in an investment at least 30% higher than dry processes.

Raw Material Consumption: The dry process boasts a higher coating material utilization rate, while the wet process may incur some loss during the cleaning process.

Energy Consumption and Operation: The dry process primarily consumes heat energy, while the wet process requires not only heat energy but also significant amounts of water and wastewater treatment costs.

👉 For small and medium-sized enterprises, the dry process is easier to implement. For large manufacturers, the wet process, while requiring a higher investment, offers more stable long-term returns.

Performance Comparison

Feel and Softness: Wet-spun leather is closer to the softness of natural leather; dry-spun leather is slightly stiffer and suitable for highly structured products.

Breathability: Wet-spun leather has a natural advantage due to its microporous structure, making it more comfortable to wear; dry-spun leather has poor breathability and can be stuffy when used in footwear or ball sports.

Abrasion Resistance and Durability: Wet-spun leather is superior, especially in high-friction environments such as ball games or car seats.

Appearance: Dry-spun leather can more easily achieve complex decorative effects such as color changes, printing, and embossing.

👉 Simply put, wet-spun leather emphasizes functionality and comfort, while dry-spun leather emphasizes appearance and efficiency.

Application Comparison

Dry-spun leather is suitable for fashionable, mass-produced products such as handbags, casual shoes, and home decor.

Wet-spun leather is suitable for products that require breathability and durability, such as footballs, basketballs, athletic shoes, and automotive interiors.

Environmental Impact and Sustainability

With tightening global environmental regulations, environmental protection has become a crucial consideration when selecting a process.

Dry Processing: Using solvent-based resins emits VOCs, requiring exhaust gas treatment equipment. However, the recent rise of solvent-free dry processing technology is improving this issue.

Wet Processing: High water consumption makes wastewater treatment a key challenge. However, advanced factories utilize closed-loop water treatment systems to minimize pollution.

👉 For customers who prioritize environmental certifications (such as REACH, ROHS, and OEKO-TEX®), it is crucial to examine suppliers’ environmental protection capabilities when selecting them.

How to Choose the Right Processing Technology

For buyers or brand owners, understanding the differences between dry and wet processing makes the next step: how to choose. Here are a few practical criteria.

Selection by Product Type

Footwear: Wet processing is recommended for athletic shoe uppers, while dry processing can be used for casual or fashion shoes.

Balls: Wet processing is essential for footballs, basketballs, and other sports to ensure wear resistance and breathability. Bags: Most choose the dry process because they don’t require high breathability but prefer decorative features.

Choose based on performance requirements

If you’re looking for softness and breathability, the wet process is more suitable.

If you’re looking for a bright appearance and intricate textures, the dry process offers greater flexibility.

If you’re looking for extreme abrasion resistance and high peel strength, the wet process offers better performance.

Choose based on budget and production volume

For limited budgets and large-scale production, the dry process is preferred.

For the high-end market, performance is a priority, and the wet process is a more worthy investment.

Yudeng’s Advantages in Pu Leather Processing

As a synthetic leather manufacturer specializing in ball and shoe leather, Yudeng has extensive experience in both dry and wet processes.

Yudeng’s Production Strengths

Yudeng boasts multiple dry process production lines as well as advanced wet process workshops, enabling flexible production adjustments based on customer needs. For different orders (such as footballs, women’s bags, and sneakers), the factory can quickly switch processes to ensure efficient delivery.

Factory Equipment and Technological Advantages

High-precision coating equipment: Ensures uniform coating and reduces defective product rates.

Energy-saving and environmentally friendly drying ovens: Reduce energy consumption and emissions.

Advanced coagulation and cleaning systems: Ensure the stable pore structure of wet-process leather.

A comprehensive testing laboratory: Ensures that every batch of leather meets international standards.

Successful Case Studies

Pu leather for soccer: Processed using a wet process, it exhibits high peel strength and wet friction resistance and has been exported to numerous European brands.

Breathable luggage leather: Processed using a dry process with a special embossing technique, it offers a stylish, lightweight, and durable appearance.

High-end athletic shoe materials: Combining the advantages of wet and dry processes, we create upper materials that combine aesthetics and comfort.

Customized Services

Yudeng offers customized services in color, thickness, and functionality (waterproof, mildew-proof, antibacterial), and provides free samples and international environmental certifications (such as REACH, ROHS, and OEKO-TEX®). For brand owners, this not only reduces supply chain risks but also enhances product competitiveness.

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

Yudeng Pu leather manufacturer has already established a leading position in the market thanks to its dual-processing approach, environmentally friendly philosophy, and international experience. In the future, Yudeng will continue to prioritize quality, environmental protection, and innovation, providing global customers with superior Pu leather solutions.