Elastic Crescent Patterned PU Leather is a functional PU synthetic leather developed specifically for jewelry boxes and high-end packaging applications, balancing decorative aesthetics with practical performance. Its surface adopts a precision embossing process to present a crescent-shaped pattern with strong dimensional depth. Under changing light, it naturally creates soft light-and-shadow contrasts, delivering an elegant and restrained visual effect. This makes it highly suitable for jewelry, watches, and premium gift boxes that demand strict appearance standards.

Structurally, the product is based on a stable multi-layer composite system. The PU surface layer offers good abrasion resistance and scratch resistance, while the middle layer provides moderate elastic support, allowing the leather to remain smooth and resilient during repeated wrapping and long-term use. With a fine hand feel and balanced flexibility, it enhances the tactile experience of jewelry boxes while also supporting downstream processing operations.

As an experienced pu leather factory, Yudeng has systematically optimized Elastic Crescent Patterned PU Leather for jewelry box applications, ensuring consistency in texture, color stability, and physical performance to meet batch production requirements. It is well suited for long-term supply and wholesale pu leather procurement models, providing brands with reliable and reproducible material solutions.

In the production of Elastic Crescent Patterned PU Leather, Yudeng establishes systematic and practical customization solutions based on the actual application requirements of jewelry boxes, ensuring that the material precisely matches customers’ product designs and manufacturing processes in terms of appearance, hand feel, and processing compatibility.

When selecting materials for jewelry boxes and high-end packaging, safety, environmental compliance, and long-term stability are key concerns for buyers. Elastic Crescent Patterned PU Leather produced by Yudeng strictly follows international standards in raw material control and production management and has passed multiple authoritative certifications, providing reliable assurance for application and export in different markets.

Yudeng’s double-sided PU leather provides both comfort and a premium look, making it a preferred material for various high-end products. Key applications include:

Luxury Furniture Upholstery: Soft and durable PU leather offers a comfortable touch for sofas, chairs, and cushions, while enhancing the aesthetic and tactile quality of home decor.

Automotive Interiors: Ideal for car seats, dashboards, and trims, providing a high-quality finish that combines durability, easy cleaning, and visual appeal.

Footwear and Bags: Double-sided PU leather adds texture, shine, and robustness to shoes, handbags, luggage, and backpacks, supporting both stitched and bonded construction.

Brand Custom Series: Enables unique surface effects, embossing, or pattern customization for branded products, enhancing recognition and differentiation in competitive markets.

Specialty and Limited Edition Products: Supports advanced surface treatments, embossing, debossing, or multi-texture combinations for limited edition or collaboration products, creating added value.

Consumer Electronics Accessories: Can be applied to headphones, protective cases, or other gadgets, providing both aesthetic appeal and functional durability.

This versatile double-sided PU leather is particularly suitable for heat pressing, bonding, or stitching applications, ensuring both secure attachment and elegant finish. By combining comfort, durability, and visual quality, Yudeng’s PU leather enhances both product appearance and user experience, making it ideal for premium markets.

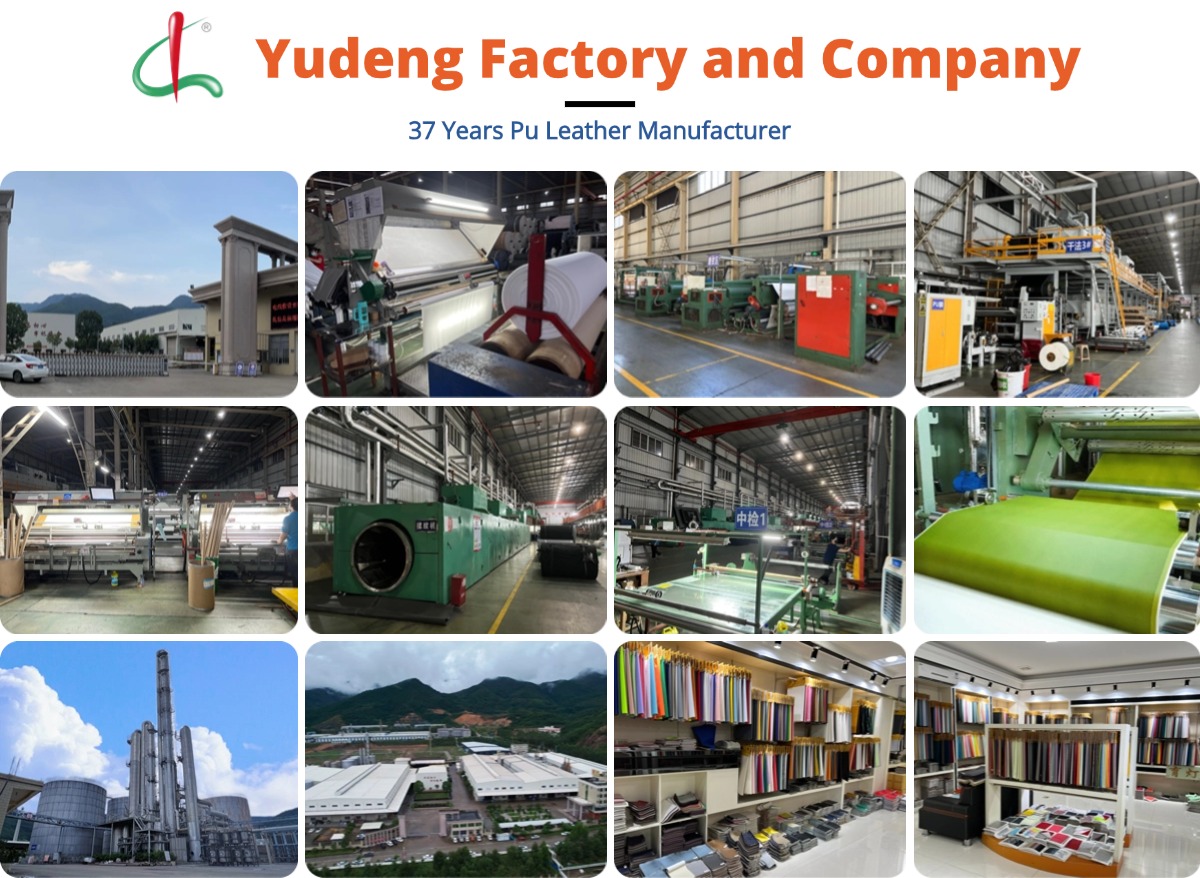

As one of China’s leading PU synthetic leather manufacturers, Yudeng has been deeply engaged in the PU leather industry for 38 years since its establishment in 1988, consistently focusing on the R&D, production, and application of mid-to-high-end polyurethane PU synthetic leather. Long-term manufacturing accumulation has enabled us to build significant advantages in product stability, process maturity, and batch supply capability.

Yudeng is not a multi-category factory but has long concentrated on PU synthetic leather as its core field. Over the past 38 years, we have continuously served markets including home decoration, jewelry boxes, bags, footwear materials, sofas, and industrial applications. We possess deep understanding of performance requirements across different application scenarios. This long-term focus allows us to continuously optimize material structures, hand-feel control, and durability to meet stable quality expectations from mid-to-high-end customers.

Yudeng’s factory covers an area of approximately 100,000 square meters, employs over 200 staff, and is equipped with 10 mature production lines, covering complete dry-process, wet-process, and finishing workflows.

Under normal production conditions, daily output can reach 150,000 meters, supporting both large-volume long-term cooperation and centralized delivery for project-based orders, providing customers with reliable supply assurance.

The factory is equipped with:

Through multi-process combined production, Yudeng can flexibly respond to PU leather customization needs across different thicknesses and application purposes.

Yudeng offers more than 400 mature leather textures, including animal patterns, natural textures, and creative designs such as crocodile, snake, lychee, sheepskin, woven, stone, and mirror finishes.

On this basis, we support customization of texture depth, density, and visual effects, helping customers create product appearances with strong brand recognition—particularly suitable for wholesale pu leather projects and long-term OEM cooperation.

Yudeng provides multiple thickness options ranging from 0.3–1.6 mm and supports different backing material combinations.

The polyurethane coating is firmly bonded to fabric or composite backings, allowing finished leather to maintain good structural stability during wrapping, cutting, and use. It is suitable for jewelry boxes, home decoration, and various industrial application scenarios.

From raw material procurement to finished product shipment, Yudeng implements full-process quality control and has passed ISO 9001 quality management system certification. At the same time, products comply with REACH, ROHS, and OEKO-TEX® international environmental standards, ensuring that PU synthetic leather meets global requirements for safety, environmental protection, and market compliance.

Yudeng Textile is a company focused on the research, development, production, and sales of high-quality polyurethane PU synthetic leather.

With 37 years of industry experience, the introduction of internationally leading production equipment and process technologies, and independently developed innovative formulas, we ensure that our products meet high industry standards in softness, abrasion resistance, weather resistance, and environmental performance.

We are committed to providing customers with eco-friendly, durable, and stylish PU synthetic leather products, widely used in jewelry packaging, footwear materials

Yudeng Textile Factory covers an area of 100,000 square meters, employs 200 staff, and is equipped with 10 production lines, with a daily output of up to 150,000 meters.

We are a 37 years factory manufacturer specializing in the production of mid-to-high-end PU leather

We specialize in the production of high-end PU leather. Our products are green, environmentally friendly and pollution-free, and are suitable for mid-to-high-end products in daily life.

We have 5 lines of dry processing, 3 lines of wet processing, 2 lines of finishing.

And daily output: 150,000 M

Of course, welcome to visit the yudeng pu leather production base

We have about more than 400 textures are avalilable,leather texture can be customized.

For urgent orders, samples can be finished in the fastest 2 days, and Mass production can be produced in 5 days.

Our minimum order quantity is: 300 meters

Yachts and ships, aerospace seats, car seat cushions, home decoration, sofas, medical equipment, sports equipment, children’s amusement park anti-collision bag facilities, etc.