As a leather with highly recognizable visual effects and excellent physical properties, crystal carbon fiber grain PU leather has become an ideal material that combines decorativeness and practicality in the field of bag manufacturing. As a synthetic leather manufacturer specializing in PU synthetic leather manufacturing, Yudeng provides customers with crystal carbon fiber grain solutions with reliable structure, clear texture and environmental compliance with superb process technology and stable delivery capabilities.

The core of crystal carbon fiber grain PU leather lies in the precise matching of its three-dimensional fiber interlaced texture + high transparent coating system. Yudeng adopts multi-layer composite structure control, which not only has a glossy appearance, but also has excellent structural strength and long-term durability.

Surface coating system:

Middle printing layer (carbon fiber pattern):

Base fabric structure:

Through this set of structural design, the crystal carbon fiber pattern PU can remain stiff and non-deformed for a long time in luggage applications, and the surface is not easy to crack and delaminate.

Yudeng supports deep customization services, covering all levels of product structure, ensuring that every design requirement of yours can be implemented:

Color customization: Supports sample color matching and Pantone number compounding, which can achieve multi-level color difference and metallic light feeling in carbon fiber texture (such as titanium silver, dazzling red, bronze, night shadow black, etc.);

Thickness customization: 0.6mm~1.5mm multiple specifications are optional, and the thickness error is controlled within ±0.03mm to adapt to different load-bearing and structural requirements;

Texture customization: On the basis of standard 3D twill, three-dimensional effects such as fishbone pattern, honeycomb pattern, and grid pattern can be developed;

Backing selection: Different base fabrics (directional knitted fabrics, low-shrinkage non-woven fabrics, etc.) are selected according to the packaging process, and are compatible with operations such as hot pressing, hemming sewing, and high-frequency pressing;

Batch delivery guarantee: The customized production cycle is controlled within 7~15 days, supporting fast proofing + stable batch supply.

We can also provide customers with “functional level expansion”, such as fire-proof, antibacterial, and anti-UV coating services for special-purpose bag projects.

Yudeng strictly implements international environmental protection and safety standards in the synthetic leather manufacturing process. The crystal carbon fiber PU leather we produce has passed the following core certifications to ensure global market access and brand reputation:

TÜV Rheinland quality and safety testing: Covering performance indicators such as wear resistance, tear resistance, adhesion fastness, flame retardancy, etc., to ensure that the finished product maintains stable performance in high-frequency use scenarios.

REACH Regulation (EC No 1907/2006) Compliance: All raw material supply chains comply with SVHC restrictions and do not contain phthalates, heavy metals and other hazardous chemicals.

ROHS Directive (2011/65/EU) Applicable: Applicable to electronic storage bags and 3C accessories packaging, ensuring the electrical safety of materials.

OEKO-TEX® Standard 100 Class II: Certified leather does not release toxic residues under long-term contact with the human body, suitable for making shoulder straps, linings and other parts that directly touch the skin.

Through the above certification system, Yudeng’s PU products can be exported to high-standard markets such as the EU, North America, Japan, and the Middle East without obstacles, meeting customers’ dual demands for regulatory compliance and brand responsibility.

The performance of this material in bag applications is not limited to appearance, but also brings significant improvements in product structural stability and service life:

High-end business boxes/travel cases: PU fabric replaces ABS material, reduces weight by 15%~20%, and has scratch and pressure resistance;

Electronic product protection bag: high structural strength, not easy to deform, suitable for VR equipment bags, audio bags, drone portable boxes;

Trendy sports backpacks: create a “technical style” appearance through surface texture and transparent coating to enhance product market recognition;

IP joint/limited handbags: provide designer brands with an important medium for visual expression and “new material marketing”

Carbon fiber texture elements have “strong visual memory points” and significant advantages in marketing visual presentation, which can empower both brand premium and user experience.

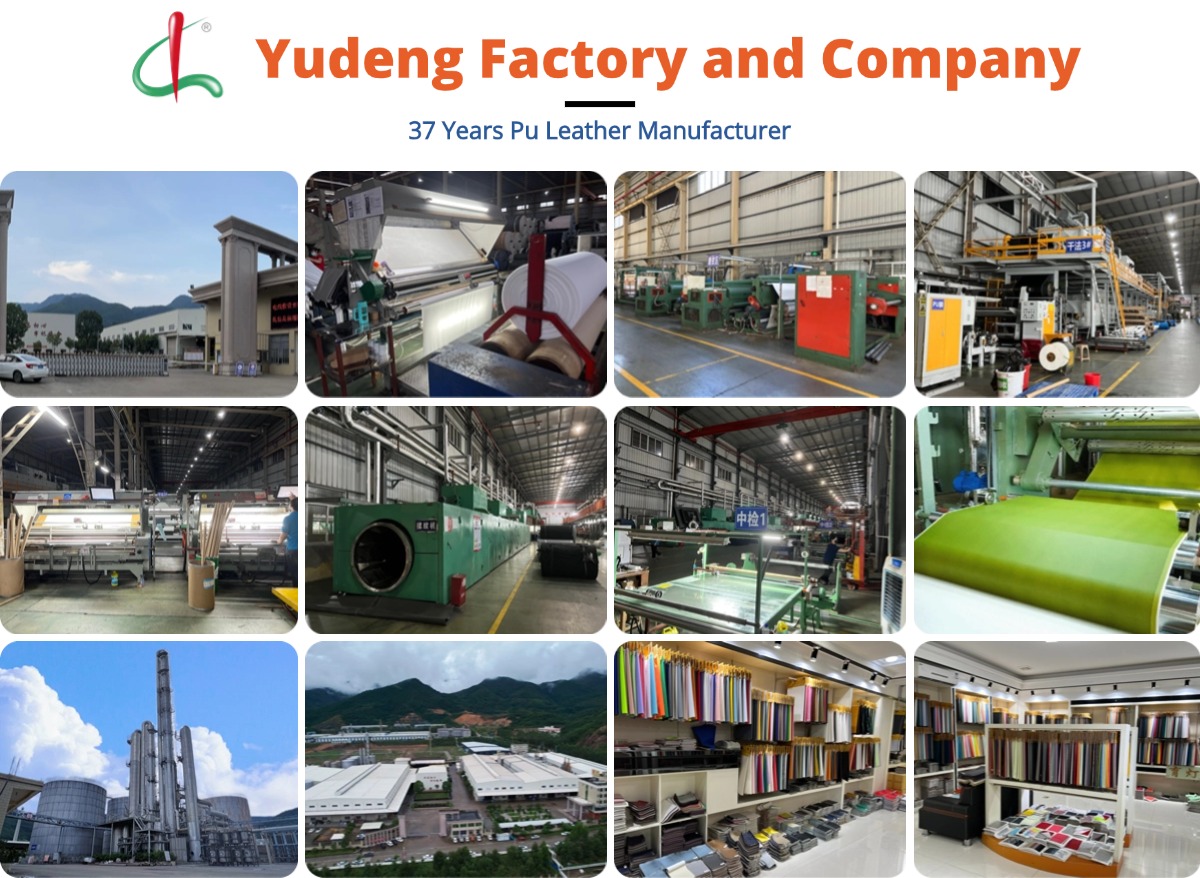

As a PU leather company factory integrating R&D, manufacturing and quality control, Yudeng insists on using manufacturing basic power to promote customer product value enhancement:

Equipment capabilities: It has 10 automatic coating production lines and imported dry and wet synthetic leather equipment, and the coating uniformity error is controlled within ±3μm.

R&D capabilities: The company has an independent material laboratory and jointly develops high weather-resistant coating formulas with top engineering teams.

Quality control system: Implement AQL 1.5 standards, with a full inspection rate of 98.6%. Products can only leave the factory after passing cold and hot shock, high temperature yellowing, and peeling tests.

Cooperating customer base: We have provided long-term and stable supply to more than 30 domestic and foreign luggage brands (including mainstream ODM customers in Europe and the United States), and support customized cooperative development.

Yudeng is not just a “material supplier”, but also a “luggage material partner” with structural optimization suggestions, supporting material coordination support and design color matching collaboration capabilities.

If you want to open up new market space for your product through material innovation, please contact us. We will provide you with samples, test parameters and structural optimization suggestions, and together give each idea a high-value landing path.

Yudeng Textile is a company focused on the research, development, production, and sales of high-quality polyurethane PU synthetic leather.

With 37 years of industry experience, the introduction of internationally leading production equipment and process technologies, and independently developed innovative formulas, we ensure that our products meet high industry standards in softness, abrasion resistance, weather resistance, and environmental performance.

We are committed to providing customers with eco-friendly, durable, and stylish PU synthetic leather products, widely used in jewelry packaging, footwear materials

Yudeng Textile Factory covers an area of 100,000 square meters, employs 200 staff, and is equipped with 10 production lines, with a daily output of up to 150,000 meters.

We are a 37 years factory manufacturer specializing in the production of mid-to-high-end PU leather

We specialize in the production of high-end PU leather. Our products are green, environmentally friendly and pollution-free, and are suitable for mid-to-high-end products in daily life.

We have 5 lines of dry processing, 3 lines of wet processing, 2 lines of finishing.

And daily output: 150,000 M

Of course, welcome to visit the yudeng pu leather production base

We have about more than 400 textures are avalilable,leather texture can be customized.

For urgent orders, samples can be finished in the fastest 2 days, and Mass production can be produced in 5 days.

Our minimum order quantity is: 300 meters

Yachts and ships, aerospace seats, car seat cushions, home decoration, sofas, medical equipment, sports equipment, children’s amusement park anti-collision bag facilities, etc.