Yudeng, established in 1988, has been focusing on the research, production, and sales of high-quality polyurethane (PU) synthetic leather for 37 years. We understand the requirements of high-end headphones for PU leather in terms of comfort, durability, and aesthetics. Every roll of PU leather undergoes strict material selection and precise craftsmanship. The surface is smooth and delicate, soft to the touch, highly wear-resistant, and elastic, with excellent breathability to ensure comfort during long-term use. Whether used for ear cushions or headbands, Yudeng’s PU leather provides premium appearance and stable performance. As a reliable pu leather supplier, we offer not only standard options but also customizable choices in color, texture, and thickness to help brands achieve unique designs.

Yudeng provides highly flexible customization to ensure each PU leather perfectly matches the design concept and brand style of clients’ headphones:

Color Customization: Supports a variety of color combinations, including metallic sheen, matte finish, and gradients, ensuring the headphone’s appearance aligns with brand tone.

Texture Customization: Offers over 400 textures, including animal patterns, ostrich, giant pebble, pigskin, melon, stone, woven, crocodile, snake, zebra, sheepskin, lychee, and bark textures, meeting diverse design needs.

Thickness & Softness Adjustment: Accurately adjusts PU leather thickness (0.3–1.6 mm) and softness according to ear cushion design and comfort requirements.

Functional Surface Treatment: Provides wear-resistant, waterproof, oil-resistant, and enhanced breathable options to extend product life and improve user experience.

Brand Customization: Supports embossing, hot stamping, or laser engraving of logos on the PU leather surface to enhance brand recognition and premium feel.

This customization capability makes Yudeng a trusted partner for high-end headphone brands worldwide, ensuring each product is unique, whether for small sample runs or mass production.

Yudeng’s PU leather products are certified by multiple international authorities, providing clients with safe and reliable high-quality materials:

TUV Certification: Ensures products meet international quality and safety standards, guaranteeing safe use in headphones.

REACH Certification: Confirms that raw materials and finished products are free from harmful chemicals, compliant with European environmental regulations.

ROHS Certification: Ensures no excessive heavy metals in the products, reducing potential environmental and health risks.

OEKO-TEX® Certification: Verifies PU leather is free of harmful substances and safe for skin, suitable for long-term contact with ear areas.

With these authoritative certifications, clients can confidently purchase for pu leather wholesale or small batch customization without concerns about compliance or safety.

Headphone PU leather not only provides soft and comfortable wearing experiences but also offers diverse textures and luster, creating unique visual effects and premium feel, making it the main material of choice for many headphone brands and custom manufacturers.

Main application areas include:

Premium headphone ear cushions: Soft and wear-resistant PU leather provides comfortable wear for over-ear headphones while enhancing product texture and quality.

Brand-customized series: Creates differentiated appearance designs for headphone brands, with color and logo customization to improve brand recognition.

Collaborations and limited editions: Supports embossing, debossing, embroidery, and special texture designs to add unique value to collaboration or limited edition headphones.

Multi-material headphone combinations: Can be combined with metal, plastic, fabric, and other materials to achieve both comfort and aesthetics, suitable for hot-pressing, bonding, or sewing processes.

This PU leather is particularly suitable for hot-pressing or bonding to ear cushions, ensuring both firmness and exquisite appearance, making headphone products outstanding in both aesthetics and experience.

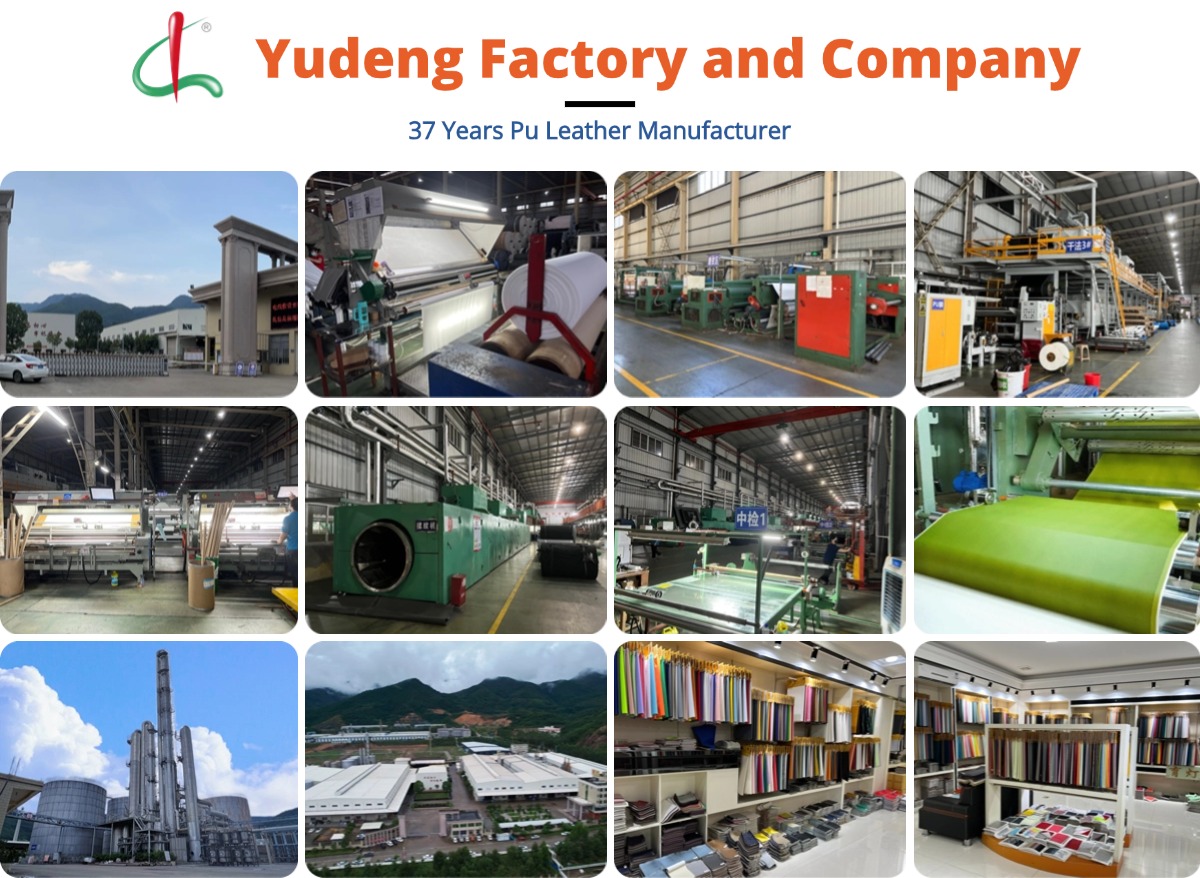

Since its establishment, Yudeng has focused on technology and quality to build an industry-leading PU leather production system:

Large Modern Factory: The factory covers 100,000 m², with 50,000 m² for production and 20,000 m² for storage, providing an efficient layout for production, inspection, and warehousing.

Advanced Production Equipment: Equipped with 10 production lines, including 5 dry processing lines, 3 wet processing lines, and 2 finishing lines, capable of coating, embossing, wear treatment, foam layer casting, and other processes.

High Production Capacity: Daily output up to 150,000 meters, supporting large-scale orders as well as fast and flexible production scheduling.

R&D and Innovative Formulas: Professional R&D team applies internationally advanced processes and proprietary formulas, ensuring PU leather meets high standards in softness, wear resistance, weather resistance, and environmental performance.

Strict Quality Control: Full-process quality monitoring, ISO 9001 certified, and GRS certified, guaranteeing each meter of PU leather meets strict client requirements and sustainable production practices.

Eco-Friendly Production: Uses environmentally friendly PU resin and solvent-free processes; products are certified by REACH, RoHS, and OEKO-TEX®, meeting client demands for green and safe materials.

With rich experience, advanced equipment, strong production capacity, and excellent customization capabilities, Yudeng Textile has become a trusted partner for many domestic and international headphone brands, automotive interiors, home sofas, and other high-end applications, providing stable, high-quality pu leather supplier and pu leather wholesale services.

Yudeng Textile is a company focused on the research, development, production, and sales of high-quality polyurethane PU synthetic leather.

With 37 years of industry experience, the introduction of internationally leading production equipment and process technologies, and independently developed innovative formulas, we ensure that our products meet high industry standards in softness, abrasion resistance, weather resistance, and environmental performance.

We are committed to providing customers with eco-friendly, durable, and stylish PU synthetic leather products, widely used in jewelry packaging, footwear materials

Yudeng Textile Factory covers an area of 100,000 square meters, employs 200 staff, and is equipped with 10 production lines, with a daily output of up to 150,000 meters.

We are a 37 years factory manufacturer specializing in the production of mid-to-high-end PU leather

We specialize in the production of high-end PU leather. Our products are green, environmentally friendly and pollution-free, and are suitable for mid-to-high-end products in daily life.

We have 5 lines of dry processing, 3 lines of wet processing, 2 lines of finishing.

And daily output: 150,000 M

Of course, welcome to visit the yudeng pu leather production base

We have about more than 400 textures are avalilable,leather texture can be customized.

For urgent orders, samples can be finished in the fastest 2 days, and Mass production can be produced in 5 days.

Our minimum order quantity is: 300 meters

Yachts and ships, aerospace seats, car seat cushions, home decoration, sofas, medical equipment, sports equipment, children’s amusement park anti-collision bag facilities, etc.