Table of Contents

Traditional football surface materials are primarily categorized into three categories: natural leather, PVC synthetic leather, and PU synthetic leather. Natural leather footballs were once favored for their softness and tactile feel. However, natural leather absorbs water easily, is unstable in weight, and requires complex maintenance, making it unsuitable for the high-frequency use and demands of modern professional competitions. While inexpensive, PVC is relatively stiff and has limited environmental performance, leading to its gradual elimination. Modern footballs are increasingly using PU leather, which not only offers a similar feel to natural leather but also boasts wear resistance, weather resistance, lightweight, and water resistance, making it ideal for professional competitions and training.

Market trends indicate that customization is becoming a new trend in football manufacturing. Globally, more and more sports brands, training centers, clubs, and promotional gift companies are developing customized footballs. This not only facilitates brand communication but also meets the specific needs of different regions and usage scenarios. In this context, choosing a professional custom PU leather football manufacturer is crucial for successfully producing high-quality footballs.

Core Properties and Technical Requirements of PU Leather for Soccer Balls

Soccer balls are subject to repeated impacts, friction, and environmental fluctuations during use. Therefore, the surface material must possess a variety of properties to ensure the ball remains stable over time. The following are the key technical requirements for PU leather for soccer balls:

Abrasion Resistance and Durability

Soccer balls frequently rub against surfaces including natural grass, artificial turf, concrete, and even sand. Inadequate abrasion resistance can easily lead to fraying, delamination, and cracking. High-quality PU leather, treated with a special coating, can withstand tens of thousands of abrasions without damage, ensuring the ball maintains its excellent appearance and longevity.

Waterproofness and Water Absorption Resistance

Natural leather soccer balls easily absorb water and become heavier in rainy conditions. High-quality PU leather, however, has a water-resistant coating on its surface, ensuring it maintains a stable weight even in rainy and humid conditions. This is a crucial characteristic for professional match balls, as it prevents weight fluctuations from affecting their trajectory.

Flexibility and Resilience

Soccer balls must provide excellent tactile feel during shooting, dribbling, and passing. The flexibility of PU leather, combined with the internal foam layer, provides a soft feel close to that of natural leather, while ensuring it remains stiff and resistant to deformation in both low and high temperatures.

Environmental Protection and Safety

Modern sporting goods manufacturing increasingly emphasizes environmental protection and sustainable development. High-quality PU leather for soccer balls typically carries international certifications such as TÜV, REACH, ROHS, and OEKO-TEX®, ensuring the material is free of harmful substances, safe and reliable, and suitable for export to high-standard markets such as Europe, the United States, Japan, and South Korea.

Key Factors in Choosing a Professional Customized PU Leather Manufacturer for Soccer Balls

For businesses, selecting a professional and reliable manufacturer is crucial to the success of their soccer ball products. The following are key considerations when selecting a manufacturer:

Raw Material Quality and Stability

High-quality PU leather requires high-quality raw materials, including high-performance polyurethane resin, a weather-resistant topcoat, and a high-quality base fabric. Only by using stable raw materials can we ensure consistent color, feel, and performance from batch to batch.

Production Technology

The production of PU leather for soccer balls involves more than simple lamination or lamination; it involves multiple steps, including:

- Foaming: Determines the leather’s softness and resilience;

- Coating: The surface coating affects abrasion resistance and water resistance;

- Embossed and textured design: Influences tactile feel, anti-slip properties, and visual effects;

- Surface functional treatments: Special effects such as matte, glossy, anti-slip, and waterproof.

Customization Capabilities

Professional manufacturers can provide customized services in color, thickness, texture, and gloss according to customer requirements. They can also add functional enhancements, such as enhanced abrasion resistance, anti-slip coatings, or lightweight designs, to meet the needs of different markets.

Factory Experience and Export Capabilities

PU leather for soccer balls is typically exported globally, so manufacturers require not only extensive production experience but also strict quality control and export experience. Understanding the company’s annual production volume, partner brands, and export markets is crucial when selecting a partner.

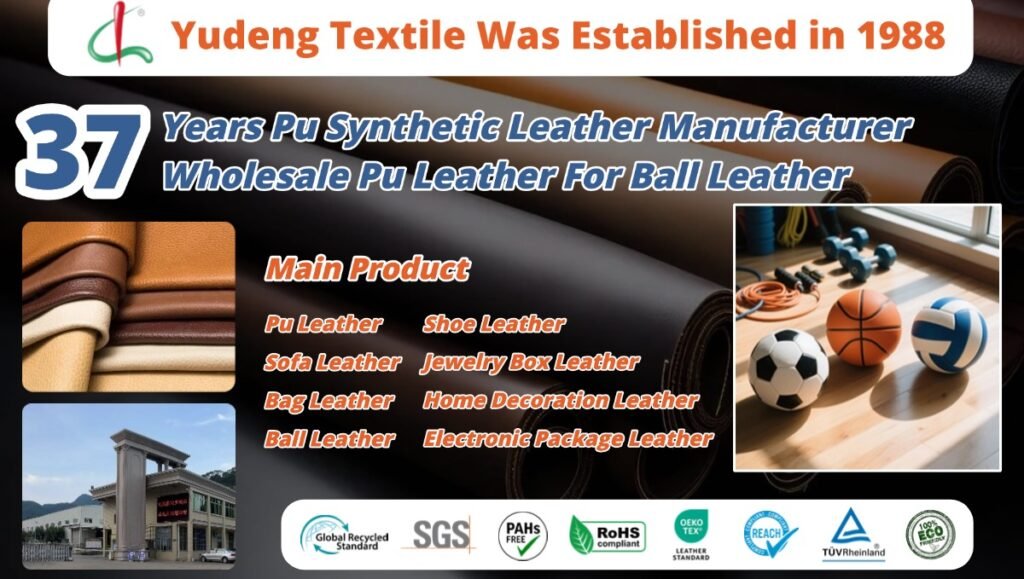

Yudeng’s Core Strengths in PU Leather Production for Soccer Balls

As a professional custom Pu leather manufacturer for soccer balls, Yudeng boasts significant advantages in R&D, production, and international collaboration:

Strong R&D Capabilities

Yudeng boasts a dedicated materials laboratory capable of conducting a wide range of tests, including abrasion resistance testing, low-temperature flexibility testing, and water resistance testing. Formulas and processes can be quickly adjusted based on customer needs to ensure leather performance meets the specialized requirements of different markets.

Comprehensive Customization Services

Yudeng offers OEM/ODM customization services, from color, thickness, texture, to gloss. Customers simply provide design references or functional requirements to quickly receive samples. We can also develop customized textures and colorways tailored to international competition standards or brand styles, enhancing product competitiveness.

Environmental Protection and Quality Assurance

Yudeng’s PU leathers hold multiple international certifications, including TÜV, REACH, ROHS, and OEKO-TEX®. We utilize a traceable production management system to ensure that every batch of leather meets export standards.

Rich Case Studies

Yudeng has long-standing partnerships with sports brands in Europe, South America, and Southeast Asia, supplying PU leather for training balls, match balls, and promotional footballs. Many customers have improved their product durability and market reputation by using our custom leather.

How to Customize Your Own PU Leather Football

For brands, trading companies, or clubs, customizing PU leather footballs is easy and can be quickly accomplished by following the following process:

Communicate Requirements

Clarify the intended use (training, competition, promotional), the intended environment (indoor, outdoor, grass, sand), the design style, and the budget.

Sample Design and Confirmation

The manufacturer will provide samples based on your requirements, including options for color, thickness, and texture, and can conduct performance testing at the sample stage.

Physical Property Testing and Adjustment

Before full production, samples can be tested for abrasion resistance, water resistance, and rebound to ensure performance meets expectations. Fine-tuning the process or formula may be performed as necessary.

Mass Production and Quality Control

After sample confirmation, the factory will initiate mass production according to international standards and implement a strict quality inspection process to ensure that every roll of leather meets the standards.

Tips:

- To enhance product competitiveness, choose special textures or custom brand embossing.

- Customers concerned with environmental trends can opt for low-VOC, recyclable PU leather.

- For export customers, we recommend prioritizing leather with international certifications to reduce trade risks.

Customer Success Stories

Customized PU leather for soccer balls is widely used in the global market, with product preferences varying across regions:

The European market prioritizes environmental standards and professional match performance, preferring leather with a soft feel and strong wear resistance.

The South American market, with its strong soccer culture, has a high demand for training and match balls, favoring bright colors and high-resilience leather.

The Asian market, balancing price and performance, is experiencing strong demand for promotional soccer balls and youth training balls.

Case Study:

- A South American training base successfully doubled the lifespan of its training balls by using wear-resistant PU leather provided by Yudeng, reducing the frequency of ball replacement.

- A European sports brand successfully passed stringent export inspection standards using Yudeng’s customized, eco-friendly PU leather, while also enhancing its green image.

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

Choosing a professional custom Pu leather company for soccer balls can ensure your soccer balls have a longer lifespan, a more comfortable feel, and greater market competitiveness. Yudeng, with its advanced production technology, international certifications, and comprehensive customization services, has become a long-term partner of numerous brands and factories.

In the future, the PU leather industry for soccer balls will focus on the following trends:

- Environmentally friendly and biodegradable materials: meeting global green manufacturing requirements;

- Lightweight, high-strength leather: meeting the dual demands of ball control and durability in professional competitions;

- Digital customization: textures, colors, and surface effects can be rapidly developed through digital processes.

If you want to create competitive soccer balls, partnering with a professional manufacturer is the first step to success. By choosing Yudeng, you not only secure a stable and reliable supply of PU leather, but also create lasting value for your brand.