Table of contents

- Why Yudeng Has Become China’s Leading PU Leather Manufacturer

- Yudeng’s Product Advantages: PU Synthetic Leather Solutions with Customization at the Core

- Yudeng’s Manufacturing Strength: Equipment, Production Capacity, and Quality Control System

- Yudeng’s Factory Service Capability: One-Stop Support from OEM to ODM

- Practical Application Scenarios of PU Leather in Different Industries

Why Yudeng Has Become China’s Leading PU Leather Manufacturer

37 Years of Focused PU Synthetic Leather Manufacturing

Since its establishment in 1988, Yudeng has always focused on the research and production of polyurethane PU synthetic leather, and now has 37 years of industry experience. Long-term dedication in a single field has enabled the company to form a mature technical system in formula optimization, material composite structure design, embossing process control, and product stability.

In the highly competitive synthetic leather market, the technical accumulation brought by continuous focus is far more valuable than short-term expansion. Yudeng ensures that its products maintain high industry standards in softness, wear resistance, weather resistance, and environmental performance through independently developed innovative formulas.

Scale Production and Industrial Cluster Advantages

Yudeng’s production base covers an area of 100,000 square meters, employs 200 staff, and is equipped with 10 production lines:

- 5 dry processing lines

- 3 wet processing lines

- 2 finishing lines

The daily output reaches 150,000 meters. Scale production brings stable delivery capabilities and cost control advantages, keeping the company competitive in the global wholesale pu leather supply system.

International Certification and Green Manufacturing Assurance

The company has passed ISO 9001 quality management system certification and obtained REACH, RoHS, OEKO-TEX®, and GRS certifications. A complete compliance system ensures that products meet environmental and safety requirements in European and American markets, providing assurance for customers to expand internationally.

Yudeng’s Product Advantages: PU Synthetic Leather Solutions with Customization at the Core

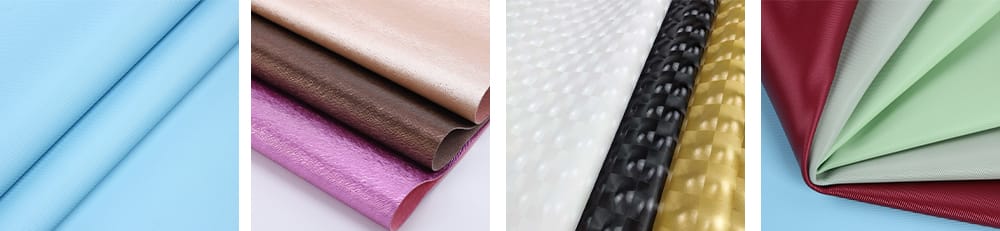

In the field of PU synthetic leather, true competitiveness lies in the ability to provide customers with deep customization solutions. Yudeng’s core advantage lies in its complete customization system, from texture design to backing material selection, to material structure and performance, all of which can meet diverse needs.

400+ Texture Library and Deep Customization Capabilities

Yudeng has a mature library of over 400 textures, covering high-end animal textures, natural textures, and modern decorative textures, supporting brand-specific customization. On this basis, customers can perform deep customization, including but not limited to:

- Texture customization: animal textures such as crocodile, snake, zebra; natural textures such as ostrich, giant pebble, pigskin, sheepskin, lychee, bark, stone, woven, cantaloupe, etc.

- Surface effect customization: matte, semi-matte, glossy, or mirror finish

- Thickness and softness customization: 0.3mm–1.6mm, adjustable according to usage scenarios

- Backing material (substrate) customization: knitted fabrics, non-woven fabrics, blended fabrics, and other customized substrates to adjust softness, resilience, and wear resistance

- Structural process customization: dry or wet processing options, composite layer number and density optimized according to functional requirements

Through these deep customization options, Yudeng provides comprehensive solutions from appearance to performance, ensuring that PU leather meets high-end standards in appearance, hand feel, and durability.

Multi-Layer Composite Structure Process

Yudeng adopts advanced multi-layer composite processes. First, a thin polymer layer is poured to form the base surface structure, followed by adhesion with the reinforced cotton-polymer layer, then a foam-like thick polymer layer is poured to enhance softness and elasticity, and finally surface embossing and gloss treatment are applied. This structural design ensures stable performance in high-frequency bending, friction, or complex environments while maintaining adjustable thickness and comfortable touch.

By combining texture customization, backing material selection, and structural design, Yudeng not only provides the material itself but also delivers implementable high-quality PU synthetic leather solutions. This full-range customization allows it to meet diverse application needs for mid-to-high-end home leather, automotive interior leather, bag leather, shoe leather, and functional industrial leather.

Yudeng’s Manufacturing Strength: Equipment, Production Capacity, and Quality Control System

Yudeng’s manufacturing strength is a key foundation for becoming China’s leading pu leather manufacturer. With 37 years of industry experience and large-scale production capacity, Yudeng has formed a complete and efficient system in equipment, production capacity, and quality control.

Yudeng’s production base covers 100,000 square meters, including 50,000 square meters of production area and 20,000 square meters of warehouse space. The factory layout is scientifically arranged to facilitate production, logistics, and quality management. The factory employs 200 staff and is equipped with 10 production lines, including 5 dry processing lines, 3 wet processing lines, and 2 finishing lines. The daily output can reach 150,000 meters, ensuring stable delivery of large domestic and international orders.

Key Production and Process Capabilities

- Dry and wet dual-process system: Dry processing is suitable for products requiring structural stability and high wear resistance, while wet processing is more suitable for high-simulation and high-breathability leather. With the dual-process system, Yudeng can flexibly choose the optimal production scheme according to customer needs.

- Multi-layer composite production process: During production, a thin polymer layer is first poured to form the base surface structure, then adhered with a reinforced cotton-polymer layer, followed by a foam-like thick polymer layer to improve softness and elasticity, and finally surface embossing and gloss treatment are applied. This process ensures thickness is flexible and controllable from 0.3mm to 1.6mm while maintaining resilience and wear resistance.

- Rapid sampling and mass production capability: Sampling can be completed within 2 days, and mass production can start within 5 days, greatly improving new product development efficiency. The minimum order quantity is 300 meters, supporting small batch trials as well as large wholesale pu leather orders.

Full-Process Quality Control

Yudeng strictly follows the ISO 9001 system in quality management, implementing comprehensive control from raw material procurement to finished product delivery:

- IQC incoming inspection: Ensures each batch of raw materials meets standards

- IPQC process control: Monitors production quality in real time

- OQC outgoing inspection: Ensures delivered products meet specifications and performance

Moreover, the company’s products have obtained REACH, RoHS, OEKO-TEX®, and GRS international certifications, ensuring environmental protection, safety, and sustainability, giving customers peace of mind for international applications.

Through scale production, advanced processes, and full-process quality control, Yudeng not only guarantees stable supply of high-end PU leather but also provides reliable production assurance, making it a trusted partner for mid-to-high-end brands and wholesale pu leather customers.

Yudeng’s Factory Service Capability: One-Stop Support from OEM to ODM

Yudeng is not only a manufacturer of high-quality PU leather but also a partner capable of providing complete one-stop services. With 37 years of industry experience and rich customization cases, Yudeng provides full support from OEM to ODM, helping brands efficiently transform design concepts into finished products.

In OEM services, Yudeng can accurately replicate the required texture, color, and thickness according to customer samples or technical parameters and provide professional suggestions on material selection. For example, if a customer requires specific softness or wear resistance, Yudeng will recommend suitable backing materials and composite processes based on product use to ensure that the finished product meets performance requirements. Sampling can be completed within 2 days, and mass production can start within 5 days, efficiently responding to urgent orders and small batch customization needs.

In ODM services, Yudeng leverages its R&D team and advanced processes to provide deeper product development support, including new texture design, functional modification (such as wear resistance, waterproofing, flame retardancy), and overall performance optimization. Through standardized project processes, Yudeng ensures that each customized project is executed smoothly: from defining the usage scenario, selecting texture and substrate, sample testing (wear resistance, bending resistance, peel strength), specification confirmation, to mass production, all steps are strictly controlled to ensure finished product effects fully meet customer expectations.

Additionally, Yudeng provides the following advantages in service:

- Rapid response and flexible production: Supports small batch trials and large-scale mass production with short sampling and production cycles

- Professional technical support: Provides material selection, process advice, and performance optimization guidance

- Full-process management of customization: From sample production to mass production, tracking every meter of PU leather to meet standards

By integrating OEM and ODM service capabilities, Yudeng not only provides high-quality PU leather materials but also deliverable design and production solutions, allowing customers to focus on brand innovation without worrying about production complexity and quality risks.

Practical Application Scenarios of PU Leather in Different Industries

Yudeng’s PU leather performs excellently in mid-to-high-end product applications, covering a wide range of industries:

- Home and sofa: High resilience formula ensures long-term use without collapsing, while maintaining softness and comfort

- Automotive and aviation seats: High bending and weather resistance, wet process suitable for complex environments

- Yachts and ships: Moisture-resistant, salt corrosion-resistant, environmental certifications ensure safety

- Jewelry packaging and bags: Exquisite textures, high-end visual effects meet brand design requirements

- Medical and sports equipment: Safe, environmentally friendly, pollution-free, REACH and RoHS certifications ensure compliance

These applications demonstrate the versatility and functionality of Yudeng pu leather manufacturer products, suitable for products with high aesthetic requirements as well as industrial or functional usage scenarios.

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

In the global trend of material upgrading, polyurethane PU synthetic leather has become an important choice for high-end products. China continues to lead the global supply system with its mature industrial chain and scale production capacity.

As a professional pu leather manufacturer with 37 years of industry experience, Yudeng relies on a 100,000-square-meter production base, 10 production lines, and a daily output of 150,000 meters, establishing a stable and reliable supply in the global wholesale pu leather market. Its 400+ texture library, deep customization capabilities, and international certification system make it not only a manufacturer but also a solutions provider.

If you are looking for a partner that combines scale, quality, and customization capabilities, Yudeng is a long-term trusted choice.