Table of contents

Whether it’s furniture upholstery, automotive interiors, electronic product casings, bag and shoe materials, or high-end decorative items, the demands for PU leather are increasingly high: it must not only be attractive and soft, but also scratch-resistant, age-resistant, sweat-resistant, and highly stable.

However, in reality, many brands encounter various problems during collaborations:

- Samples look good, but batch production is inconsistent.

- Colors and textures are severely inconsistent.

- Environmental and compliance requirements fail to meet the buyer’s expectations.

- Low delivery times and communication efficiency lead to extended development cycles.

The essence of these problems is not price, but rather an inaccurate assessment of the PU leather manufacturing system and customization capabilities.

As a team with years of experience in deep customization of PU leather and electronic leather manufacturing, Yudeng focuses not only on the material itself, but also on:

- 👉 How can the material truly meet the product’s structural needs?

- 👉 How to ensure batch stability and long-term availability?

- 👉 How to achieve rapid market penetration and support brand growth in Brazil?

Yudeng’s Custom PU Leather Manufacturing System

A superior custom PU leather partner must possess the ability to replicate stable batches, which stems from four key aspects:

1) Raw Material Management System

Good PU leather isn’t determined by a single step, but rather by rigorous control starting from the moment raw materials enter the factory:

- Supplier Qualification Management

- Raw Material Batch Inspection

- Resin and Additive Performance Records

This ensures consistent performance from the first roll to the 100,000th roll.

2) Standardized Process Routes

By establishing standardized process flows (such as coating thickness, drying temperature, embossing parameters, etc.), batch variations caused by human factors are avoided.

3) Strict Testing and Verification Mechanism

Key performance tests are conducted before shipment:

- Bending Cycle

- Abrasion Cycle

- Color Stability

- Top Coating Adhesion

This is both a quality guarantee and a long-term quality commitment.

4) Tracking Feedback and Optimization System

Even after materials have been mass-produced and shipped, excellent manufacturers continue to follow up on usage feedback and continuously optimize subsequent batches. This is especially important in a global supply chain, significantly reducing the risk of rework and returns.

PU Leather Customization Process and Key Control Points

The base fabric structure is the “skeleton” of PU leather; different skeletons determine the overall mechanical properties of the material.

Common base fabric structures and typical applications:

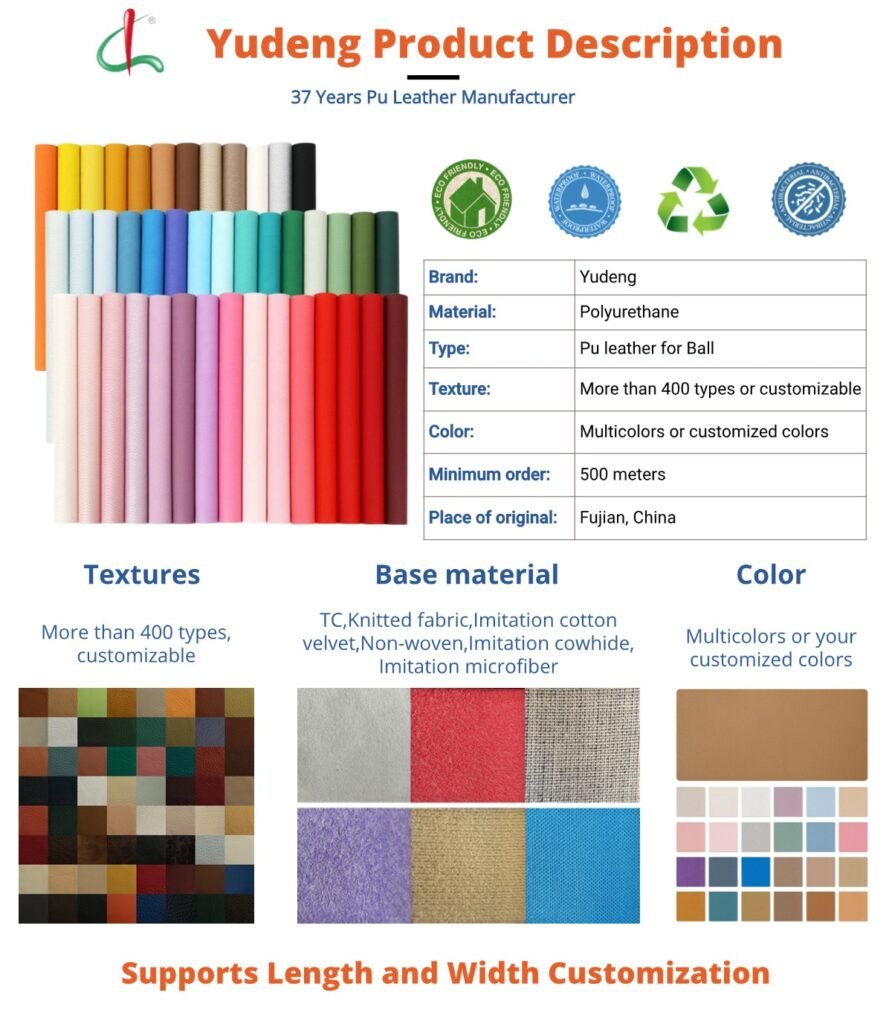

| Base Fabric Type | Main Advantages | Recommended Use Cases |

| High-Density Knitted Base Fabric | Balances softness, folding resistance, and stability | Furniture, car seats |

| Woven Base Fabric | High strength, tear resistance | Highly durable products |

| Non-woven Fiber Base Fabric | Lightweight and soft | Electronic casings, lightweight goods |

| Microfiber Reinforced Base Fabric | Premium feel | High-end handbags, appliance fabrics |

Coating System Design

PU coating is not a simple single layer, but a structural system composed of multiple functional layers stacked together, each with a specific function:

- Base Coating: Provides the basic structure and adhesion

- Middle Layer: Determines thickness, elasticity, and overall abrasion resistance

- Top Layer: Determines feel, appearance, stain resistance, and abrasion resistance

The overall performance of high-quality PU leather is not just about “looking good,” but about the targeted design of each layer. For example:

- For oil resistance: Apply a stain-resistant coating to the surface.

- For sweat resistance: The top coating must be enhanced with chemical resistance.

- For scrub resistance: Enhance the abrasion resistance structure of the middle coating.

Practical Advice: Clearly define your actual needs during the sample communication stage (e.g., stain resistance, sweat resistance, abrasion resistance, etc.), rather than simply saying “I want a pretty color.”

Surface Treatment and Texture Refinement Design

PU leather not only needs to meet structural performance requirements but also needs to satisfy the product’s aesthetic expectations.

Yudeng supports the following surface design features:

- Multiple embossed textures (matte fine lines, simulated leather textures, tech-inspired textures, etc.)

- Multiple gloss levels (high gloss, semi-matte, full matte)

- Different tactile sensations (silky, soft, dry)

- Customized logo embossing or brand identification markings

These are not simple decorations, but rather a product expression achieved through different molds, embossing depths, and coating structures.

Applications in Balls and Sporting Goods: Advantages of Pu Leather

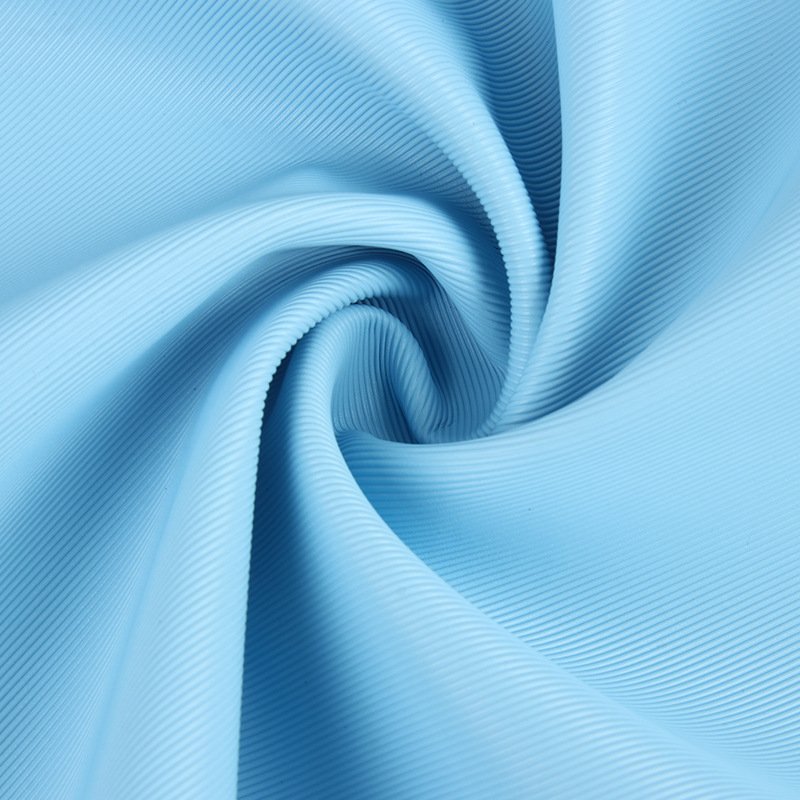

Sporting goods, especially balls like soccer, basketball, and volleyball, place extremely high demands on materials. They must withstand prolonged friction and impact while maintaining excellent feel and control. This is precisely where Pu synthetic leather shines.

Why is Pu synthetic leather so popular in balls?

- Excellent wear resistance: Training and match balls endure thousands of kicks and abrasions daily, and Pu leather maintains its surface integrity.

- Comfortable feel: Its soft touch and ergonomic design make it easier for athletes to display their skills.

- Weather resistance: Pu leather is more stable than PVC in rainy, humid, and high-temperature conditions.

- High-end positioning: Official balls for international tournaments are mostly made of Pu synthetic leather to ensure fair and professional competition.

Pu leather is widely used not only in balls but also in sports shoes, boxing gloves, fitness equipment, and other products due to its combination of softness, durability, and aesthetics. For manufacturers, Pu synthetic leather provides a stable material base, ensuring products maintain performance in harsh environments.

Yudeng’s Expertise and Customization Advantages in Pu leather Manufacturing for Balls

As a Pu leather factory specializing in Pu leather manufacturing for balls, Yudeng has accumulated years of experience and technical advantages in the industry. Unlike general leather suppliers, Yudeng not only offers standardized products but also offers in-depth customization based on customer needs.

Yudeng’s advantages are primarily reflected in the following aspects:

- Diverse Material Options: We offer Pu leather in varying thicknesses, hardnesses, and surface textures to meet the needs of various balls, such as soccer, basketball, and volleyball.

- Strong Customization: Customers can select color, finish (matte, glossy, textured), and environmental standards (such as REACH and ROHS certification).

- Stable Quality Control: Yudeng utilizes advanced testing equipment to rigorously control wear resistance, tear resistance, and aging resistance.

- Environmental Protection and Compliance: Our factory’s production processes meet international environmental standards, helping customers’ products successfully enter markets such as the EU and North America. OEM/ODM Services: Yudeng goes beyond simply providing materials and offers complete solutions for ball brands.

Thanks to these advantages, Yudeng has become a long-term partner of numerous international sports brands. For buyers seeking high-quality Pu synthetic leather, Yudeng is undoubtedly a reliable choice.

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

Amid the global manufacturing transformation and upgrading, Pu synthetic and artificial leather continue to hold an irreplaceable position due to their price advantages, performance advantages, and environmental potential.

For buyers, understanding the differences between Pu and other artificial leathers can help them more accurately position their products in the market.

For Pu leather manufacturers, choosing the right supplier, such as Yudeng, ensures product quality and brand credibility.

For consumers, the increasing popularity of Pu synthetic and artificial leather means they can enjoy products with exquisite appearance and superior performance at more reasonable prices.

In the future, with the increasing application of water-based PU and biodegradable materials, these synthetic leathers will continue to evolve towards a more environmentally friendly and intelligent direction. In high-performance applications such as balls and sporting goods, the application of Pu synthetic leather will only expand.