In today’s highly competitive consumer goods market, the appearance of a product is not only the first factor to attract users, but also an important part of brand tone, positioning and personalized expression. PU synthetic leather, as a material widely used in shoes, bags, furniture, car interiors, electronic accessories and other fields, the design of its surface texture directly affects the visual impression and tactile experience of the terminal product. Compared with traditional general textures, customized textures can provide more recognizable and more brand-friendly solutions.

With the increasing market demand for high value-added products, more and more brands are turning to customized services. Yudeng is a leading polyurethane leather manufacturer responding to this trend. With more than 15 years of R&D and production experience in the PU synthetic leather industry, it has successfully provided texture customization solutions for many well-known brands at home and abroad. Yudeng’s texture customization service is not just a simple imprint of surface patterns, but also a complete set of system engineering from drawing development to process proofing, from mold manufacturing to mass production.

Yudeng will comprehensively analyze how to help customers achieve the goal of “customized texture is brand logo” through advanced equipment, professional process flow and profound technical background, and help products achieve differentiation, personalization and market competitive advantages.

Table of Contents

- The core advantage of Yudeng texture customization

- Detailed explanation of the five major process flows of PU synthetic leather texture customization

- How to cooperate with Yudeng for texture customization? Complete service process and suggestions

- Application example: Analysis of successful cases of customization in multiple industries

- Professional knowledge blessing: How to judge the texture quality and craftsmanship level?

The core advantage of Yudeng texture customization

With more than 100 texture templates and OEM/ODM capabilities

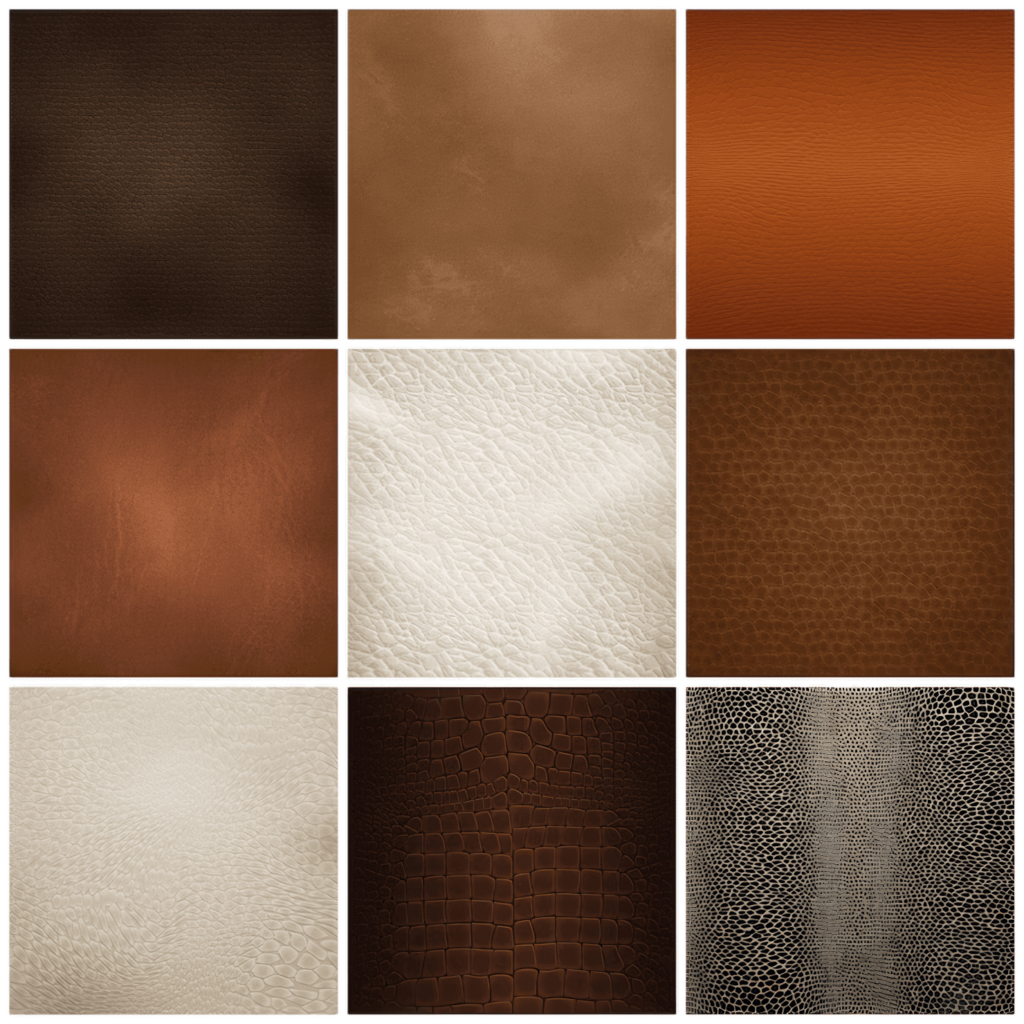

Yudeng has accumulated more than 100 mature PU synthetic leather texture samples, from classic lychee, cross, and nappa patterns to popular volcanic rock patterns, water ripples, and carbon fiber patterns in recent years, covering high-end, retro, technology, minimalist and other styles. Customers can create secondary creations or directly customize new patterns in basic textures. Yudeng not only provides ODM services, but also supports OEM texture development from 0 to 1, that is, texture reproduction based on design sketches or reference objects provided by customers.

Self-developed texture mold and embossing roller system

Many small factories on the market rely on purchased molds and rollers, resulting in long customization cycles, large errors, and poor repeatability. Yudeng is equipped with its own mold development center, using CNC precision engraving technology to manufacture texture molds and rollers. Through micron-level engraving precision, the texture is clear and the depth is consistent, and it can cope with complex curved surfaces and multi-layer embossing requirements.

Full process control from raw materials to surface treatment

The presentation of texture depends not only on the mold, but also on multiple variables such as the substrate, coating thickness, chemical ratio, and dry and wet processes of PU leather. Yudeng has the ability to independently regulate the formula in the synthesis of PU raw materials, and can match the most suitable foaming ratio, primer material and coating thickness according to different texture requirements. For example, soft textures require low-density and high-elasticity foaming structures, while technological textures rely more on high-hardness glossy layer coating.

Ensure batch consistency and texture stability

The key issue faced by most texture customization is the consistency guarantee from samples to batch products. Yudeng has a digital monitoring system and an infrared texture deviation monitor in the production of each PU synthetic leather to ensure that the texture depth error is within ±0.03mm and the embossing positioning deviation is controlled within ±1mm, which greatly improves the yield rate and customer satisfaction.

Detailed explanation of the five major process flows of PU synthetic leather texture customization

Process 1: Texture design and development

The first step of customized service starts with design. Yudeng has an internal texture design team equipped with professional design software (such as AutoCAD, SolidWorks, Photoshop, etc.) and a texture generation modeling system, which can scan customers’ drawings, reference pictures or physical objects to generate high-precision texture patterns. Customers can choose single-layer texture or multi-layer superimposed texture design at this stage.

Process 2: Mold making and embossing principle

After the design is confirmed, Yudeng will start the mold engraving process. The roller mold material is made of high-strength alloy steel or chrome-plated alloy aluminum. The CNC five-axis linkage engraving machine is used to complete the pattern concave and convex structure, and it is heat-treated and surface-plated to improve wear resistance and cleanliness. After the mold is completed, hot pressing or cold pressing tests are carried out to evaluate whether the texture details can be perfectly transferred.

Process 3: Substrate and coating process control

The texture is not only beautiful on the surface, but also involves the precise regulation of the base foaming structure and surface coating system of PU synthetic leather. For example, the wet process is suitable for complex textures and gives stronger adhesion, while the dry process is sharper in the presentation of embossed details. In addition, TPU coating can bring excellent stretching and rebound performance, while PVC surface is more conducive to the performance of high-gloss layers.

Process 4: Embossing and texture composite process

After completing the substrate preparation, the texture pressing stage will be entered. Yudeng uses fully automatic high-temperature embossing equipment (150~220℃), combined with air pressure and rolling adjustment, to achieve high-precision texture transfer. For textures that require multi-layered textures (such as 3D leather textures, three-dimensional engraved textures, etc.), composite embossing can be used, that is, the basic texture is first formed, and then the second texture pattern is superimposed to achieve a three-dimensional texture.

Process 5: Post-processing and surface effect enhancement

In order to make the texture more realistic and tactile, surface treatments such as waxing, oil spraying, laminating, cold stamping, etc. can also be performed. For example, furniture PU leather often uses matte coating to simulate the texture of genuine leather, while high-end footwear PU prefers bright anti-scratch spraying. Yudeng can customize the post-processing process combination according to the customer’s terminal needs.

How to cooperate with Yudeng for texture customization? Complete service process and suggestions

Step 1: Demand research and design communication

The customer provides the target texture sample, physical object or text description, and the Yudeng team will conduct a preliminary technical feasibility assessment and solution proposal within 48 hours, including design cycle, proofing suggestions, cost budget and other contents.

Step 2: Proofing and technical evaluation

After confirming the plan, enter the small batch sample production stage. Yudeng generally completes the sample production within 7 to 10 working days, and the customer can make corrections after receiving it. This stage focuses on evaluating the texture transfer accuracy, feel, color matching and structural compatibility.

Step 3: Small batch testing and process verification

After the customer confirms the sample, he can choose a small batch trial production (500~1000 meters) for terminal testing, including sewing adaptation, wear resistance, bending resistance test, etc. Yudeng simultaneously optimizes the production process at this stage.

Step 4: Production of bulk goods and quality assurance

After entering the formal bulk stage, Yudeng implements the ISO9001 quality management system, and conducts texture consistency testing, color comparison and surface strength testing on each batch of materials to ensure that the factory quality is controllable and reliable.

Step 5: Logistics delivery and after-sales service

Yudeng has its own warehousing system and long-term cooperative logistics channels, supporting sea transportation, air transportation and multi-country express services, and also provides technical consulting services, such as customized texture PU material usage suggestions, supporting structure design solutions, etc.

Application example: Analysis of successful cases of customization in multiple industries

Footwear brand: Customized “rock crack” texture upper PU

A European and American outdoor shoe brand is looking for wear-resistant and natural upper materials. Yudeng has developed a series of “rock crack” textures through 3 rounds of proofing, with scratch resistance ≥ 2000 times and washable performance. It has been cooperating for more than 3 consecutive years.

Furniture industry: Customized solution for simulated leather embossing

An Italian furniture brand cooperated to customize the “retro leather texture” texture, using dry micro-embossing technology + cold-ironing matte spraying, while retaining the visual impact, achieving skin-friendly feel. Customer feedback shows that high-end customer satisfaction has been significantly improved.

Automotive interior: Matte technology texture instrument PU leather

An electric car brand customized PU leather for interior instrument panel covering, which needs to have flame retardant, aging resistance, and technological texture effects. Yudeng developed a nano-dot matte texture, with a TPU coating layer, to meet the EN 45545-2 fire protection standard requirements.

Professional knowledge blessing: How to judge the texture quality and craftsmanship level?

Three core evaluation indicators:

- Texture accuracy: Use a magnifying glass to check the clarity of the texture edge, with a standard error of <±0.05mm; Abrasion resistance: Using TABER 5135 friction tester, the number of abrasions >1500 times is excellent;

- Consistency: Multi-segment sampling to compare the depth of the texture, the error is controlled within ±5%.

Recommended testing tools:

- Laser displacement meter: measure texture depth and concave-convex consistency;

- Friction tester: test scratch resistance and wear resistance;

- UV accelerated aging box: test surface weather resistance.

Authoritative standard reference:

- REACH (EU Chemical Substance Registration Certification)

- ROHS (Electronic Environmental Protection Material Requirements)

- ISO9001 (Quality Management System)

- SGS Texture Uniformity Third-Party Report

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

Today, with the increasingly obvious trend of consumption upgrading, brands are not only logos and design languages, but also the expression of materials and details. Texture is the most intuitive part of these expressions. With its industry-leading mold development capabilities, sophisticated process control systems, and perfect customization service processes, Yudeng provides brand customers with not only synthetic leather textures, but also an “extension of brand texture”.

If you are looking for a reliable, professional polyurethane synthetic leather partner with extensive texture development experience, Yudeng is undoubtedly a trustworthy choice. Contact us now to create a PU texture customization solution that belongs to your brand’s exclusive language!