Against the backdrop of the global manufacturing industry being highly segmented and the increasing trend of personalized consumption, customization has become an important development direction for the materials industry. PU (polyurethane) synthetic leather, as a material that combines environmental performance with versatility, is widely used in shoes, bags, furniture, automobiles, clothing and other fields. Compared with traditional genuine leather, PU leather is not only more cost-controlled, but also can achieve diversified textures, colors, feel and functions through processes, making it an ideal choice for all kinds of brands and processors.

As a Pu leather factory focusing on the research and development and manufacturing of PU synthetic leather, Yudeng is committed to providing customers with truly “tailor-made” solutions. From product proofing to mass production support, from environmental performance to visual design, Yudeng uses real experience and technology to create materials that combine beauty, durability and functionality for customers.

Table of Contents

- Why has PU synthetic leather become a hot material for customization?

- What are the customization options for PU synthetic leather?

- What is the process of customizing PU synthetic leather?

- What are the application scenarios of customized PU synthetic leather?

- What are the advantages of Yudeng’s customized PU synthetic leather?

Why has PU synthetic leather become a hot material for customization?

The fundamental reason why PU synthetic leather has quickly taken a dominant position in many industries and has been widely included in the customization process is its material controllability, environmental protection and appearance diversity.

Obvious performance advantages: PU leather has good wear resistance, water resistance, tear resistance, and is soft and elastic. Modern polymer blending technology can also give it special functions such as flame retardant, antibacterial, and breathable, which is very suitable for industries that require functionality.

Strong visual and tactile flexibility: Unlike natural leather, which is limited by the state of raw materials, the appearance design of PU leather is almost unrestricted. Different effects such as matte, pearlescent, metallic, printed, and embossed can be achieved through mold texture, coating process, and color paste ratio, which can better serve branded and fashionable product development.

Environmental protection trend promotion: The environmental cost and ethical controversy of traditional animal leather are increasing year by year around the world. PU synthetic leather meets the requirements of current environmental regulations, can use water-based polyurethane formulas to reduce VOCs emissions, and can pass international certifications such as REACH, ROHS, and CA65 to meet the needs of the European and American markets.

Reasonable cost control: Compared with genuine leather, PU leather has an absolute advantage in cost control per unit area, and its quality is stable and easy to process. It can effectively reduce uncertainties in mass production and facilitate supply chain optimization.

What are the customization options for PU synthetic leather?

Customizing PU synthetic leather is not as simple as “changing the color”. A professional customization solution should cover the following dimensions, so that the product can truly meet the purpose and design positioning from the inside out.

Color customization: Color is the first element of visual communication. Yudeng supports color matching in various ways such as color number, physical proofing, and specified formula, providing accurate color matching capabilities with color difference controlled within △E≤1.0.

Thickness selection: The common thickness range of PU synthetic leather is 0.4mm~2.0mm. Different thicknesses are suitable for different purposes, for example:

- 0.6~0.8mm: suitable for handbag interiors and lightweight shoe uppers

- 1.0~1.2mm: suitable for furniture, sofas, and luggage

- 1.4~1.8mm: suitable for car seats and heavy-load structural parts

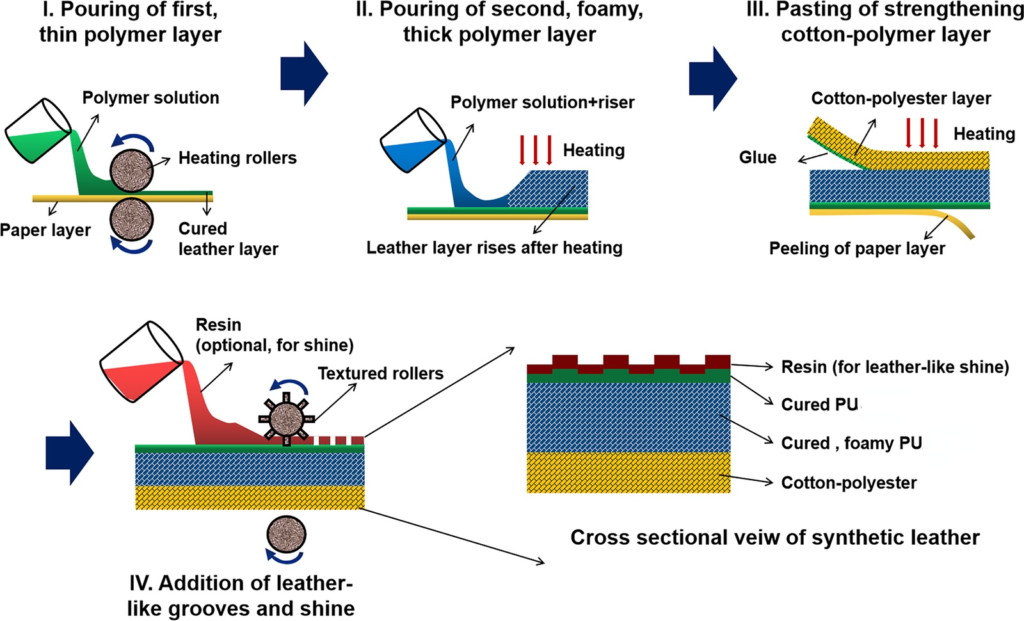

Surface texture and texture: Through mold embossing, dry foaming or wet casting process, PU leather can achieve rich texture performance: such as lychee texture, nappa texture, crocodile texture, carbon fiber texture, suede texture, etc., and the surface feel can also be adjusted, such as smoothness, softness, and resilience.

Functional addition: According to industry needs, PU leather can be added with various functional additives, such as flame retardant, antibacterial, mildew-proof, scratch-resistant, UV-resistant, etc.

Base fabric structure selection: PU synthetic leather is usually composed of PU resin and base fabric, and the base fabric determines the overall tensile strength and ductility. Common base fabrics are:

- Non-woven fabric (light, economical)

- Polyester knitted fabric (high ductility, comfortable)

- Cotton/blended fabric (skin-friendly, natural style)

- Microfiber base fabric (higher strength and durability)

Through the above multi-dimensional combination, the customizability of PU synthetic leather has reached a highly flexible state.

What is the process of customizing PU synthetic leather?

An efficient and rigorous customization process is the key to ensuring quality and delivery cycle. Yudeng has summarized a set of standardized and transparent customization processes to help customers clearly control from concept to implementation.

Demand communication stage: Salesmen and engineers participate together to deeply understand the customer’s purpose, usage environment, target price and appearance requirements.

Sample development and confirmation: After confirming parameters such as color, thickness, and texture, Yudeng provides free proofing services with test reports attached.

Material preparation and trial production: After the sample is confirmed, the factory optimizes the resin formula and base fabric according to the confirmed parameters, and starts small-batch trial production for customer trials or inspections.

Customer confirmation and mass production: After the customer feedback is correct, formal production is started, and the ERP system is used to control each batch of raw materials and outbound codes to ensure traceability of the entire process.

Delivery and after-sales support: Provide complete COA and third-party test data at the time of delivery, and follow up and feedback to customers regularly.

What are the application scenarios of customized PU synthetic leather?

The customization capability of PU synthetic leather has enabled it to penetrate widely into multiple industrial chains. The following are several industry application directions that Yudeng currently serves:

Footwear manufacturing: sports shoe uppers, sandal linings, boot uppers, insole backings, etc. There are high requirements for breathability, bending resistance, and appearance texture.

Luggage and leather goods: backpacks, handbags, wallets, business card holders. They must be scratch-resistant, wear-resistant, stylish, and lightweight.

Home furniture: sofa fabrics, soft-covered wall panels, office chairs. They usually focus on comfort, flame retardancy, and large-area color difference control.

Automotive interiors: dashboards, seat coverings, door linings. They are required to be resistant to high temperatures, UV-resistant, and not easy to volatilize.

Clothing and wearable devices: leather jackets, leather skirts, gloves, hats, earphone covers, watch straps, etc. The focus is on skin-friendly comfort, lightness, softness, and fashionable expression.

Consumer electronics packaging: such as PU earphone bags, mobile phone leather cases, tablet protective cases, etc. They must take into account protection, brand tone, and high-end visual style.

Yudeng has equipped corresponding process development teams and quality control standards for the above different fields to ensure that customers in each industry can obtain the most matching PU material solutions.

What are the advantages of Yudeng’s customized PU synthetic leather?

With many years of experience in the PU leather industry, Yudeng has built a strong customized service capability in multiple dimensions.

Professional team: The company has a complete team from formula engineers, colorists, proofing masters to quality inspection engineers. All processes are developed internally without outsourcing to ensure delivery and quality control.

Advanced equipment: Equipped with multiple sets of dry and wet production lines at home and abroad, fully automatic color matching system, texture drum customization system, constant temperature and humidity storage warehouse, etc., which can realize the rapid switching of different textures and surface processes.

Rigorous testing system: It has its own testing laboratory, covering more than ten standard tests: including wear resistance, peeling, VOC release, yellowing resistance, flame retardant grade, etc., to meet the standards of European, American and Southeast Asian markets.

Flexible service mode: Support OEM and ODM dual modes, the minimum order quantity is as low as 300 meters, the fastest delivery of proofing is 3 days, and small batch trial production is flexible and convenient, suitable for start-up brands and big brands to develop and use simultaneously.

Customer collaborative development capabilities: Yudeng cooperates with many international brands to develop exclusive textures and functional leathers. For example, a European luggage brand cooperated with Yudeng to develop a mid-to-high-end environmentally friendly PU leather with both natural leather feel and high scratch resistance, which has received good market response.

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

In today’s increasingly competitive manufacturing industry, standardized products can no longer meet the needs of brand personalization and high quality. As a highly adjustable and high-performance material, PU synthetic leather is naturally suitable for customized development. Whether you are a startup brand exploring differentiated design or a mature enterprise seeking high-performance environmentally friendly material solutions, Yudeng can provide you with a one-stop service from “demand insight” to “material landing” with a professional perspective, flexible capabilities and rigorous processes.

Through Yudeng’s in-depth analysis, I believe you have a systematic understanding of the customization options, application areas, development processes and Yudeng’s service system of PU synthetic leather. If you are looking for a partner who can understand your needs and provide you with truly competitive material solutions, Yudeng PU leather manufacturer will be a trustworthy choice. Contact us now to make every piece of PU leather truly meet your brand vision and product requirements.