Table of contents

Understanding Custom PU Synthetic Leather and Its Advantages

- Structure and Composition: Custom PU synthetic leather is made of a textile base layer, a polyurethane coating, and a surface treatment. The base layer provides strength and durability, the PU layer offers abrasion resistance, softness, and moderate elasticity, and the surface layer creates textures and gloss while providing waterproofing. Yudeng’s PU leather ranges from 0.3 mm to 1.6 mm in thickness, with backing usually made of fabric or a fabric blend for support.

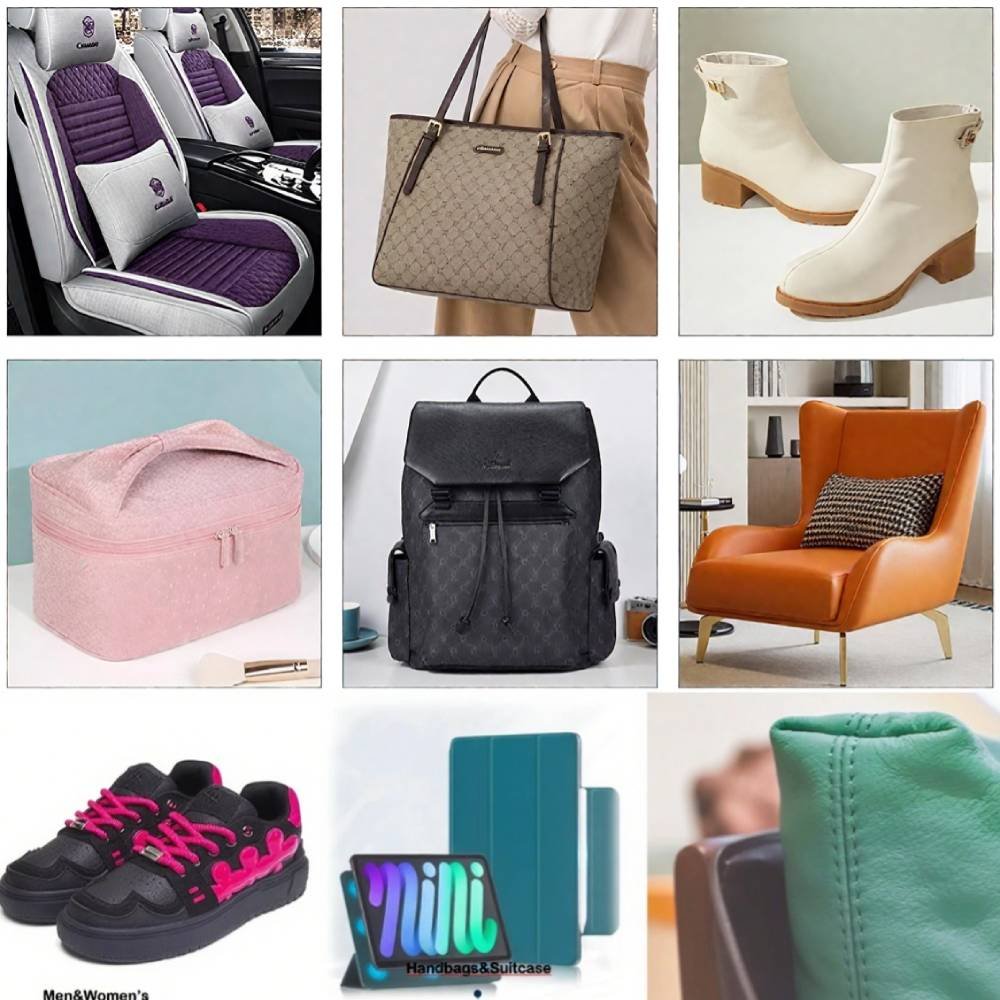

- Diverse Texture Options: Yudeng offers over 400 textures, including smooth glossy, rough matte, animal patterns, ostrich, crocodile, snake, zebra, sheep, lychee, bark, and mirror finishes. Customers can customize textures and colors for furniture, footwear, bags, and industrial products.

- Comparison with Genuine Leather and PVC Leather: PU leather is cost-effective, flexible to process, and eco-friendlier than genuine leather. Compared to PVC leather, it is closer to natural leather in feel, with better breathability and durability. It exhibits high abrasion resistance, elasticity, and weather resistance, making it suitable for mid-to-high-end furniture, automotive interiors, footwear, and bags.

- Applications: Custom PU leather is widely used in yachts, aerospace seats, car cushions, home décor, sofas, medical devices, sports equipment, and children’s playgrounds. Adjustable thickness, texture, and hardness allow products to meet high standards for aesthetics, comfort, and durability.

Yudeng’s History and Industry Experience

- Company Establishment and Development

Yudeng Textile was established in 1988, focusing on the research, production, and sales of high-quality PU synthetic leather. Since its founding, the company has continuously accumulated production experience and technical expertise, evolving from a small-scale manufacturer into an international enterprise with modern production facilities and an R&D system. Key milestones include the expansion of leather production lines in 2004, the construction and commissioning of the Datuan Yudeng Industrial Park in 2013–2014, and the implementation of a lean production line in 2018. By 2025, the company operates 10 production lines with a daily output of 150,000 meters. - Factory Scale and Production Capacity

Yudeng Textile occupies an area of 100,000 square meters, employs 200 staff, and has 10 production lines, including 5 dry-process, 3 wet-process, and 2 finishing lines, with a daily production capacity of 150,000 meters. The warehouse space is ample, capable of meeting large-scale custom orders. - International Certifications and Quality Management

Yudeng implements comprehensive quality control from raw material procurement to finished product delivery. The company is certified under ISO9001 quality management system and holds GRS certification, ensuring sustainable and responsible production practices. Its products also comply with REACH, RoHS, and OEKO-TEX® international environmental standards, providing safe and eco-friendly high-quality PU leather. - Industry Experience and Professional Reputation

With 37 years of industry experience and long-term international partnerships, Yudeng demonstrates professional advantages in PU leather R&D, production management, and application promotion. Clients can evaluate reliability through company history, export cases, and certification credentials, establishing long-term collaboration.

Yudeng’s Production and Technical Advantages

- Advanced Production Equipment: Yudeng has introduced internationally advanced production equipment to achieve highly efficient automated manufacturing, ensuring uniform thickness and smooth surface in every batch. The factory operates 10 production lines, including dry-process, wet-process, and finishing lines, capable of meeting diverse custom needs.

- Professional Manufacturing Processes: The PU leather production process includes pouring the first thin polymer layer, bonding an enhanced cotton-polymer layer, pouring a second thick foam-like polymer layer, and forming embossed textures and gloss through pressing. This process ensures PU leather is soft, abrasion-resistant, highly elastic, and weather-resistant.

- Independent R&D and Innovative Formulas: Yudeng maintains an in-house laboratory to develop new PU formulas and perform performance tests. Adjustments can be made to coating thickness, hardness, texture, and color according to customer requirements, along with testing for lightfastness, abrasion resistance, and chemical resistance, ensuring mass-produced products meet high standards.

- Eco-Friendly Production: Yudeng uses environmentally friendly PU resins and solvent-free production processes, actively responding to green manufacturing principles, while ensuring product performance in softness, durability, weather resistance, and environmental protection meets industry standards.

Global Application Cases of Custom PU Leather

- Furniture and Automotive Interiors: Yudeng PU leather is widely used in sofas, office chairs, and home decoration, with moderate thickness and natural textures that are both aesthetically pleasing and durable. In car seats and dashboards, the products exhibit lightfastness, abrasion resistance, and wrinkle resistance, meeting long-term use requirements.

- Footwear and Bags: In footwear, PU leather can be adjusted for softness and elasticity to ensure comfort and durability. In bags, Yudeng provides diverse textures and colors, combining excellent hand feel with high-quality appearance.

- Yachts, Aerospace, and Industrial Components: Yacht and aerospace seats require high durability and weather resistance, which Yudeng meets through precise processing and high-performance coatings. In industrial components, sports equipment, and children’s playgrounds, PU leather provides waterproofing, scratch resistance, and chemical resistance, suitable for demanding environments.

- Medical and Specialized Applications: Yudeng PU leather is also applied in medical device surfaces, rehabilitation equipment, and protective facilities, balancing safety, durability, and comfort to support high-standard industries.

Best Practices for Working with Yudeng

- Sample Evaluation and Confirmation

After submitting custom requirements, Yudeng provides small batch samples for evaluation, including color, texture, thickness, and hand feel, ensuring mass production meets design expectations. - Pre-Production Quality Control

Following sample confirmation, small batch trial production ensures consistency. Tests for abrasion resistance, lightfastness, and chemical resistance guarantee final products meet international standards. - Long-Term Collaboration and Delivery Management

Yudeng supports a minimum order of 300 meters, with mass production delivery within 5 days. Clients can establish long-term partnerships, with regular quality checks and feedback to ensure continuous optimization and supply stability.

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

With 37 years of experience in PU synthetic leather R&D and manufacturing, modern production equipment, innovative formulas, and extensive custom experience, Yudeng has become a leading synthetic leather manufacturer and pu leather manufacturer in the world. Whether for furniture, automotive interiors, footwear, bags, industrial, medical, or specialized applications, Yudeng provides high-quality, customizable, eco-friendly, and durable PU leather.

Choosing Yudeng as a partner offers enterprises reliable material assurance, efficient custom services, and professional technical support to enhance product value and market competitiveness.