Table of contents

- Yudeng PU Leather Factory and Dry Process Production Line Overview

- Principles and Advantages of Dry Production Processes

- Key Equipment and Operational Procedures for Dry Production Lines

- Quality Control and Testing Methods for Dry-Process PU Leather

- Practical Recommendations for Collaborating with PU Leather Manufacturers

Yudeng PU Leather Factory and Dry Process Production Line Overview

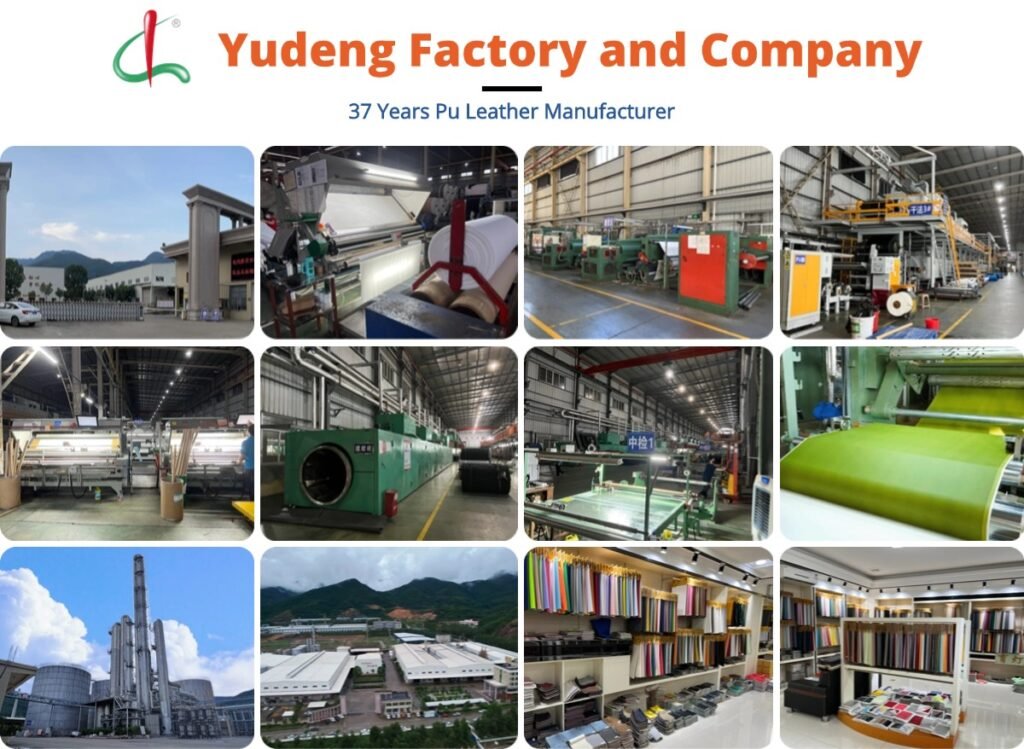

- Factory History and Development Background: Established in 1988 and located in Jinjiang City, Fujian Province, China, Yudeng PU Leather Factory specialises in the research, development, production, and sales of high-quality PU synthetic leather. Through years of development, the factory has become one of the industry’s leading manufacturers, possessing extensive experience and technological expertise.

- Factory Scale and Equipment: Occupying over 20,000 square metres, the facility houses multiple dry production lines and more than 200 advanced machines. Equipment encompasses coating machines, drying and curing apparatus, embossing presses, and post-treatment machinery, enabling fully automated production from raw material preparation to finished goods dispatch.

- Certifications and Standards: Yudeng holds ISO 9001 Quality Management System and ISO 14001 Environmental Management System certifications, ensuring every batch of PU leather meets international quality and environmental standards. Standardised management enables strict control over production processes, guaranteeing product stability and consistency.

- The Pivotal Role of Dry Production Lines: Dry production lines form Yudeng’s core competitive advantage. Compared to traditional wet processes, dry production offers energy efficiency, environmental sustainability, and high productivity. It enables precise control over coating thickness and drying temperatures, ensuring consistent leather softness, abrasion resistance, and appearance.

- Application Scenarios and Customisation Capabilities: The dry production line supports manufacturing PU leather in diverse thicknesses, textures, and functionalities. Products find extensive application in furniture upholstery, automotive interiors, footwear materials, and premium luggage sectors. The factory offers bespoke services, tailoring textures, colours, tactile qualities, and functionalities to client specifications for personalised production.

Principles and Advantages of Dry Production Processes

Core Differences Between Dry and Wet Methods

Dry production does not rely on soaking or washing. The PU coating forms a film through continuous application and hot-air drying. Compared to wet methods, dry processes reduce water consumption while shortening production cycles and lowering energy consumption and pollution emissions.

Principles of Dry Process Technology

PU liquid is uniformly applied to the substrate surface via coating equipment, then enters hot-air drying units to cure and form a film layer. Subsequent embossing and post-treatment ensure the leather exhibits a soft handfeel, abrasion resistance, and colour stability.

Advantages of the Dry Process

Dry production offers the following benefits:

- Energy-efficient and environmentally friendly: Reduces energy consumption and solvent emissions by 30–50%.

- High efficiency: Achieves output of 500–800 square metres per hour in a single shift, suitable for large-scale production.

- High controllability: Precise regulation of coating thickness and drying temperature ensures consistent leather performance.

- Consistent Quality: Eliminates coating irregularities or bubbling caused by moisture re-penetration inherent in wet processes.

Quality Impact

The dry process optimises PU polymer ratios and plasticiser formulations, enabling PU leather with varied hardness, elasticity, and abrasion resistance. This meets diverse requirements across furniture, footwear materials, and automotive interiors.

Key Equipment and Operational Procedures for Dry Production Lines

- Raw Material Preparation and Pre-treatment: Select high-quality fabric or synthetic leather substrates. Perform cleaning, surface activation, and primer coating to enhance coating adhesion. Tension control ensures substrate flatness and wrinkle-free application during coating.

- Coating Operation and Uniformity Control: Employ high-precision coating equipment to uniformly apply PU liquid material onto substrate surfaces. Adjust blade height and speed to achieve coating thicknesses of 0.3–1.2 millimetres. Monitor coating quality in real-time during production to prevent uneven thickness or air bubbles.

- Drying and Curing: Post-coating, materials enter hot-air drying equipment for curing. Employ segmented temperature control: low-temperature pre-drying followed by high-temperature curing to enhance abrasion resistance. Regulate humidity and air velocity to ensure smooth, crack-free film formation.

- Post-Processing and Embossing: The dried PU leather undergoes embossing, finishing, and surface treatment. Embossing imparts natural or creative textures, while finishing enhances abrasion resistance and water repellency. Final quality assurance is conducted through manual or automated inspection.

- Common Issues and Solutions: Coating Blistering: Adjust thickness and drying temperature; increase degassing treatment. Film Cracking: Optimise PU formulation and plasticiser ratio. Colour Variation: Standardise coating formulations and environmental conditions; utilise a colour difference meter for inspection.

Quality Control and Testing Methods for Dry-Process PU Leather

Laboratory Testing Procedures

- Abrasion Resistance: The Martindale abrasion tester simulates usage environments to ensure surface durability without delamination.

- Fold Resistance: The flexing tester assesses resistance to creasing, guaranteeing crack-free performance during prolonged use.

- Colour Fastness: Standardised testing for light exposure, friction, perspiration, etc., verifies colour stability in compliance with international standards.

- Thickness and Density: Precision instruments measure coating thickness and density to guarantee uniformity.

Application of ISO and Industry Standards

Strict adherence to ISO9001 and ISO14001 systems, alongside reference to GB/T, ASTM and other standards for production and testing, ensures artificial leather factory products maintain competitiveness in international markets.

Data Analysis and Production Optimisation

Data on coating thickness, drying temperatures, and production speeds are collected to establish a production database. This enables quality issue tracking and process optimisation, achieving stable and efficient production.

High-Quality Output Assurance

Automated equipment guarantees precise operational repeatability. Process monitoring promptly detects anomalies, while a highly skilled technical team conducts regular maintenance and calibration of equipment. This ensures stable, high-quality output in dry production processes.

Practical Recommendations for Collaborating with PU Leather Manufacturers

- Selecting Reliable Suppliers: Prioritise factories holding ISO certification and possessing established dry production lines. Conduct on-site inspections of equipment, production environments, and process flows. Review case studies and client testimonials to ensure proven expertise.

- Sample Testing and Customisation Communication: Prior to mass production, obtain samples for texture, abrasion resistance, and colourfastness testing. Provide detailed customisation requirements—such as thickness, texture, colour, and functional specifications—and confirm these in writing or via electronic documentation.

- Considerations for Small-Scale and Mass Production: For small batches, focus on minimum order quantities, lead times, and production flexibility. For large-scale production, ensure equipment capacity, process stability, and batch consistency.

- Cost Control and Efficiency Optimisation: Leverage the high efficiency of dry production methods to reduce energy and labour costs. Optimise logistics and inventory management to minimise raw material wastage. Coordinate with factories to adjust production schedules, enabling on-demand manufacturing.

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

Yudeng PU Leather Factory has established itself as a benchmark for professionalism and reliability within the PU leather factory / artificial leather factory sector through its advanced dry production lines. The dry process not only enhances production efficiency but also ensures the softness, abrasion resistance, and colour stability of PU leather. Through a rigorous quality control system and data-driven optimisation methods, Yudeng guarantees that every batch of leather meets stringent custom requirements.

Whether for furniture, footwear materials, or automotive interiors, dry-process PU leather delivers exceptional performance and aesthetic appeal. Understanding the dry production process and partnering with specialist manufacturers provides robust support for product quality and market competitiveness. Leveraging experience, technology, and professional services, Yudeng offers globally sourced, high-quality, customisable PU leather solutions, exemplifying industry excellence as a PU leather factory and artificial leather factory.