Table of contents

Why PU Leather is the Ideal Choice Across Industries

PU leather (Polyurethane Leather) is a synthetic material primarily made of polyurethane (PU). With its outstanding performance and sustainable characteristics, it has become the preferred choice for numerous industries worldwide. It not only closely resembles genuine leather in appearance and texture but also offers advantages such as durability, flexibility, water resistance, and eco-friendliness, making it highly sought after in the market.

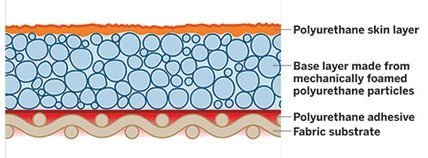

Structurally, PU leather consists of three layers: a polyurethane surface layer, a fabric or non-woven backing, and an intermediate composite layer. This multi-layer structure provides excellent elasticity and breathability. The PU surface is processed through professional embossing and coating techniques, achieving visual effects ranging from smooth glossy to fine matte. Its abrasion resistance generally exceeds 30,000 cycles, far surpassing traditional leather, ensuring a longer service life.

Compared to genuine leather, PU leather has several notable advantages:

- High consistency: Unlike natural leather, which may have flaws and color variations, PU leather offers uniform texture and stable color.

- Easy maintenance: PU surface is waterproof and stain-resistant, requiring minimal care.

- Superior environmental performance: No animal hides are used, and production processes can control emissions, aligning with modern sustainability principles.

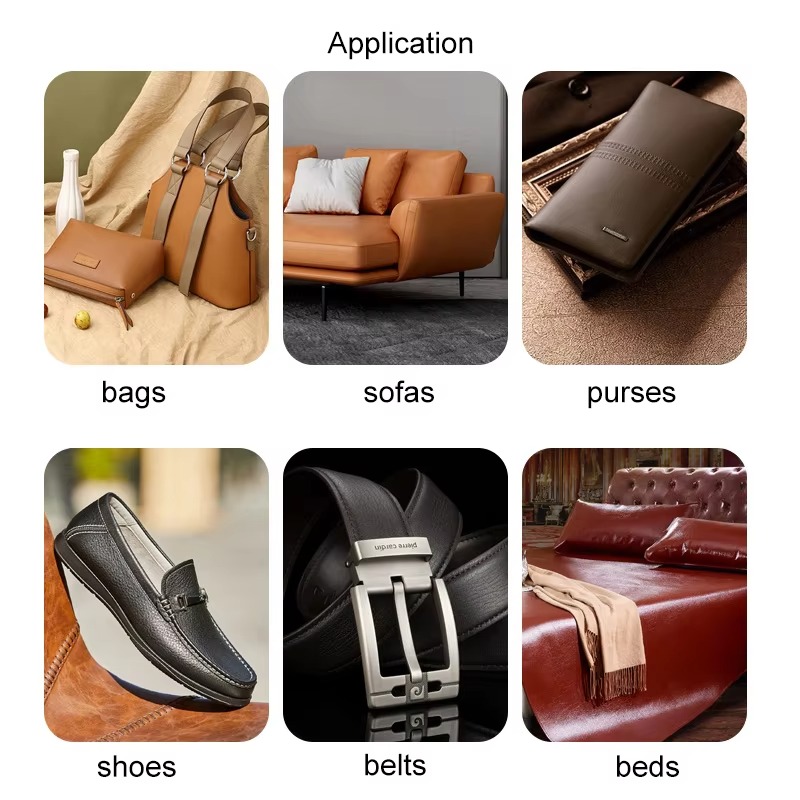

Today, PU synthetic leather is widely applied in automotive interiors, furniture decoration, footwear and bags, as well as electronic product casings and packaging design. Its soft touch, excellent durability, and eco-friendly properties make it the ideal balance for designers and manufacturers seeking quality and responsibility.

Yudeng as a Professional PU Leather Manufacturer: Technology and Strength

As a pu leather manufacturer with 37 years of experience, Yudeng Textile has been dedicated to the research, production, and sale of high-quality polyurethane PU leather since its establishment in 1988. Headquartered in Jinjiang, Fujian, the factory covers 100,000 square meters, with 10 modern production lines, over 200 employees, and a daily output of 150,000 meters, serving customers worldwide.

(1) Intelligent Production System and Core Processes

Yudeng employs internationally advanced production techniques, including dry, wet, and composite coating methods. The factory is equipped with:

- 5 dry processing lines: for producing PU materials with stable structure and uniform thickness.

- 3 wet processing lines: suitable for products requiring high breathability and softness.

- 2 finishing lines: for embossing, printing, dyeing, glossy finishes, and post-processing.

The production workflow includes polymer layer casting → backing lamination → embossing and shaping → surface coating → quality inspection and packaging. Every step is monitored by automated equipment and intelligent detection systems, ensuring consistent, high-quality products.

(2) Strict Quality Control and Certification System

Yudeng has obtained ISO9001 quality management certification, REACH, RoHS, and OEKO-TEX® Standard 100 certifications, complying with EU and North American environmental regulations. The factory is also GRS certified, using eco-friendly PU resin and solvent-free production processes, actively responding to green manufacturing principles.

(3) Strong R&D Capability and International Cooperation

Yudeng has an independent R&D laboratory and testing center, capable of abrasion testing, colorfastness testing, weather resistance experiments, and surface tension analysis. Through proprietary formula optimization, the company develops specialized PU leather for various applications, such as automotive-grade high-temperature leather, antibacterial and mold-resistant leather, flame-retardant leather, and scratch-resistant packaging leather.

Over the years, Yudeng has maintained stable cooperation with multiple international brands, providing customized PU leather solutions that meet design and environmental standards, establishing itself as a reliable pu leather factory in the industry.

Detailed Customization Options: From Texture to Backing

Yudeng’s greatest advantage in PU leather customization lies in its high flexibility and wide selection. The company offers over 400 texture templates and supports customers’ custom textures. Key customization options include:

(1) Texture Customization

Yudeng provides textures based on customer design requirements:

- Litchi grain (common in furniture and footwear, delicate texture)

- Nappa grain (soft like genuine leather, suitable for high-end sofas and interiors)

- Snake, crocodile, zebra textures (used for fashion bags and shoes)

- Carbon fiber, woven, bark textures (used in automotive and electronics packaging)

Precision embossing rollers and laser engraving molds allow for faithful reproduction from natural textures to unique patterns.

(2) Backing and Base Material Customization

Yudeng offers various backings, including non-woven, knitted, microfiber, and elastic fabrics. Different base materials directly affect PU leather’s tensile strength, thickness stability, and hand feel:

- Non-woven backing → cost-effective, suitable for packaging and low-load applications.

- Microfiber backing → high-end, offering excellent wear resistance and softness.

- Elastic fabric backing → often used in automotive and aerospace seats, combining stretch and resilience.

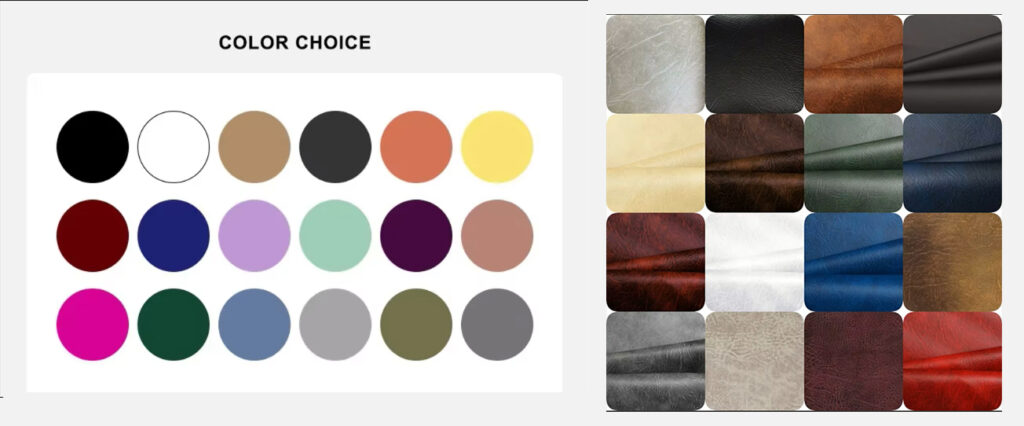

(3) Color, Thickness, and Surface Effects

Yudeng supports multi-dimensional customization:

- Thickness: 0.3mm–1.6mm

- Surface: matte, glossy, pearlescent, metallic

- Color: based on PANTONE standard with computer color matching, ensuring ΔE ≤ 1.0

Applications and Industry Trends of Custom PU Leather

PU leather applications have long surpassed traditional apparel and bag fields, showing remarkable potential in home furnishing, automotive, medical, and electronics industries.

- Furniture and Interior Decoration: PU leather is widely used in sofas, wall panels, headboards, and table surfaces. Its wear-resistant and waterproof properties ensure durability in high-use environments. With UV and stain-resistant treatment, Yudeng’s home furnishing PU leather can last over 10 years.

- Automotive and Transportation Seats: Automotive PU leather requires high heat resistance, flame retardancy, and mold prevention. Yudeng’s automotive-grade PU leather passes FMVSS 302 flame retardancy testing and is adopted by various bus and yacht manufacturers.

- Footwear and Bag Industry: Lightweight and flexible PU leather, with multi-color texture options, has become mainstream for shoes and handbags. Yudeng offers high-elasticity, fold-resistant PU leather that withstands 100,000 folds without cracking.

- Electronics and Luxury Packaging: High-end electronics and jewelry brands prefer high-gloss, mirror-finish PU leather for packaging. Yudeng’s customized formulas provide scratch resistance and pressure texture, enhancing both aesthetics and durability.

- Industry Trends: The future of PU leather will focus on eco-friendly PU with solvent-free processes to reduce VOC emissions, the use of recycled materials to promote circular economy, digital customization via AI-generated textures and automated color matching, and functional PU with antibacterial, breathable, and temperature-regulating properties. Yudeng is actively integrating AI texture recognition and 3D prototyping technology, advancing PU leather customization into a smart, innovative era.

Why Choose Yudeng as Your Custom PU Leather Partner

Choosing Yudeng means selecting not only an experienced pu leather manufacturer but also a reliable, innovative partner:

- 37 years of experience and technical expertise, with a rich formula database

- Fast prototyping and small-batch production: 2 days for samples, 5 days for mass production

- Strict quality and supply chain management: full tracking from raw material to finished product

- Trusted by global clients: products exported to over 50 countries, including Europe, the U.S., and Southeast Asia

- Brand value enhancement: Yudeng’s custom PU leather increases design recognition and competitiveness

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

In an era emphasizing sustainability and innovation, PU leather has become a key material for modern industries due to its eco-friendliness, durability, and versatility. With 37 years of professional experience, a comprehensive customization system, and an international perspective, Yudeng has established itself as a leading pu leather manufacturer and a trusted pu leather factory worldwide.

Whether you are in furniture, automotive, fashion, or packaging, Yudeng provides professional expertise, abundant textures, and customized services to help realize unlimited product design possibilities, letting material details extend your brand value.