Table of contents

- Yudeng: Pioneer in PU Synthetic Leather Manufacturing in China

- Analysis of the Core Ingredients of Yudeng PU Synthetic Leather

- Customization Capabilities: Comprehensive Selection from Material to Function

- Yudeng: High Production Efficiency and Strict Process Control

- Advantages of Collaborating with Yudeng and Success Cases

Yudeng: Pioneer in PU Synthetic Leather Manufacturing in China

Company History and Industry Experience

Established: Yudeng Textile has been focusing on high-quality PU synthetic leather research, production, and sales since 1988, with 37 years of industry experience.

Development timeline:

- 1988: Yudeng Textile founded in Jinjiang

- 2004: Leather production lines completed

- 2013–2014: Datuan Yudeng Industrial Park constructed and put into operation

- 2018: Datuan Lean Production Line started operation

- 2025: Factory equipped with 10 production lines, daily output reaching 150,000 meters

Factory Scale and Production Capacity

- Factory area: Total 100,000 m², including 50,000 m² production area and 20,000 m² warehouse

- Employees: 200, covering R&D, production, quality control, and customer service

- Production lines: 5 dry processing lines, 3 wet processing lines, 2 finishing lines

- Daily output: Up to 150,000 meters, capable of handling large orders while supporting small batch customization

Certifications and Environmental Commitment

- ISO9001 Quality Management System certification

- OEKO-TEX Standard 100, REACH, and RoHS environmental certifications

- GRS certification ensures sustainable production and green manufacturing

Industry Position and Market Coverage

- Yudeng is one of the leading pu synthetic leather manufacturers in china

- Products are exported to over 50 countries and regions including Europe, America, Southeast Asia, and the Middle East

- Clients include domestic and international mid-to-high-end brands, covering footwear, bags, furniture, apparel, and home decor

Corporate Culture and Competitive Advantages

- Corporate culture: Innovation, quality, customer-first

- Core competitiveness: High production capacity, flexible customization, strict quality control, and fast market response

- Features: Can handle large-scale orders while supporting small batch and personalized customization for diverse client needs

Analysis of the Core Ingredients of Yudeng PU Synthetic Leather

PU synthetic leather is not a single layer, but rather a multi-layered structure. Yudeng has systematic R&D and production experience in this area, enabling it to adjust its formula to suit different application scenarios.

Base Fabric Layer

The base fabric layer, typically made of polyester fiber or non-woven fabric, serves as the “skeleton” of PU leather, determining its overall strength and toughness. Yudeng prioritizes fiber uniformity and density when selecting the base fabric, ensuring it maintains lightweight while also possessing sufficient tensile strength.

Coating Layer

The coating layer, made of polyurethane resin, is the core component of PU leather. Yudeng utilizes a solvent-free PU formula, significantly reducing VOC (volatile organic compound) emissions during production. This not only complies with international environmental standards such as REACH and RoHS, but also makes the finished product safer and more environmentally friendly.

The performance of the coating layer directly impacts the lifespan of a ball product. Yudeng’s optimized formula significantly improves:

- Abrasion resistance: According to TABER abrasion resistance testing, Yudeng’s PU leather can withstand over 100,000 friction cycles, significantly exceeding that of ordinary materials.

- Flexibility: Even in low-temperature environments, it remains resistant to cracking. Waterproof and

- Breathable: A special formula makes the leather waterproof while retaining a certain degree of breathability, ensuring the ball retains its feel even in wet conditions.

Surface Treatment Layer

This is the outermost layer of the PU leather and the layer that comes into most contact with the user. Yudeng’s surface treatments include anti-slip particles, a scratch-resistant coating, and a UV-resistant coating. This combination of processes ensures that the PU leather is more durable in actual use, retains its color longer, and resists fading.

In summary, the advantages of Yudeng’s PU synthetic leather composition lie not only in performance but also in environmental and sustainability considerations. These factors make it highly competitive in the international market.

Customization Capabilities: Comprehensive Selection from Material to Function

Buyers often require more than just a roll of leather; they require materials tailored to the needs of specific markets and user groups. Yudeng’s customization capabilities allow each brand to find the solution that best suits their needs.

Thickness and Feel Customization

Different balls require significantly different leather thickness and feel requirements. For example:

- A soccer ball requires a tough yet lightweight outer layer to ensure speed and durability. Basketballs prioritize grip and abrasion resistance.

- Yudeng can adjust the thickness between 0.8mm and 2.0mm based on customer needs, and control the softness through a foaming process.

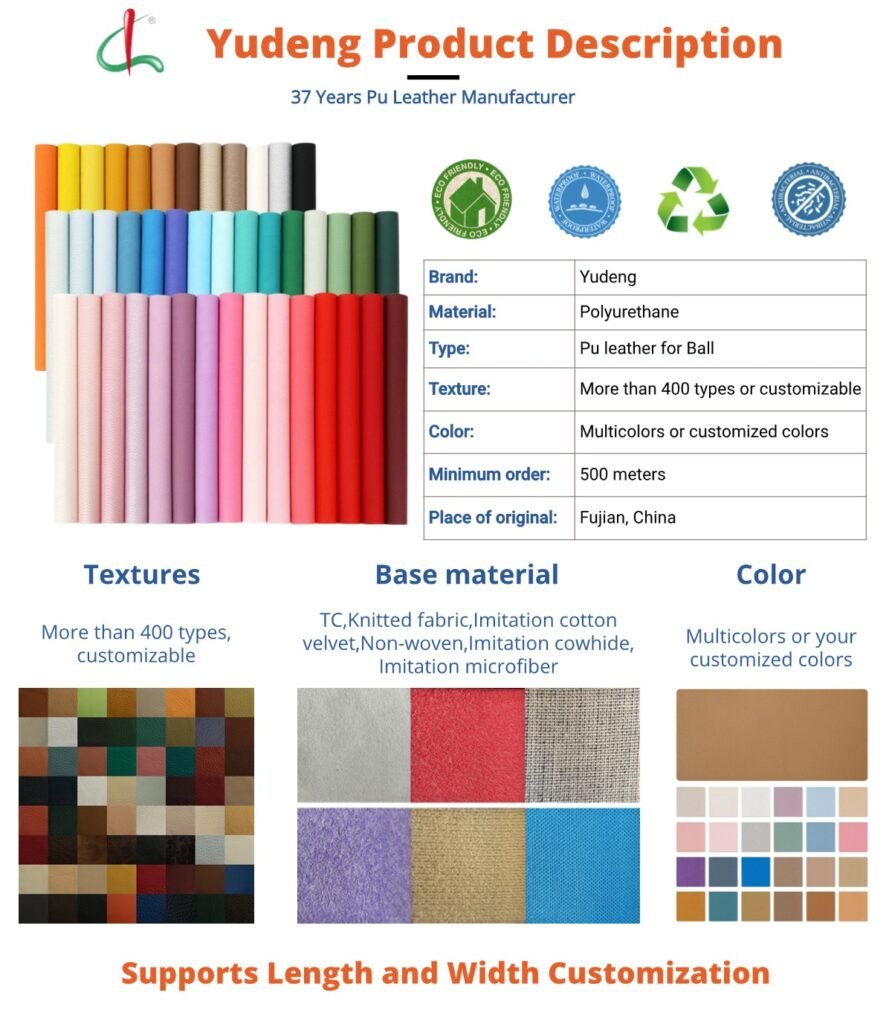

Color and Texture Customization

Sports brands prioritize the unique appearance of their products. Yudeng can customize a variety of colors, textures, and embossing techniques based on customer designs, such as lychee grain, cowhide grain, and a smooth finish.

Functional Craftsmanship

Yudeng also offers additional functional craftsmanship, such as:

- Anti-slip surface: Enhances ball control during play.

- Scratch-resistant treatment: Suitable for extended use.

- UV-resistant treatment: Ensures color retention during outdoor use.

OEM/ODM Customization Services

Yudeng goes beyond simply providing raw leather materials and participates in the customer’s product development process. The OEM/ODM model provides support from concept design to finished product. This capability is particularly suitable for sports brands seeking to create differentiated products.

Through these customized options, buyers can closely integrate their brand philosophy with the material’s properties, creating balls that truly meet market demand.

Yudeng: High Production Efficiency and Strict Process Control

Yudeng has a systematic production management system covering every step from raw material procurement to finished products, with strict process control to ensure consistent product quality.

Production Process

- Raw material procurement: Strict selection of high-quality polyurethane, base materials, and eco-friendly dyes, all tested before entering the factory

- Dry/Wet processing: 5 dry lines, 3 wet lines to ensure efficient production for different processes

- Finishing process: 2 finishing lines for surface embossing, hot stamping, and backing lamination

- Testing and packaging: Each batch undergoes tensile strength, wear resistance, color fastness, and thickness tests to meet customer standards

Production Capacity

Daily output up to 150,000 meters, capable of handling large orders, while small batch rapid sampling can also be executed flexibly.

Quality Control Methods

- Tensile strength test: ensures leather does not easily tear

- Wear resistance test: simulates long-term friction for durability

- Color fastness test: includes rubbing and light fastness to ensure lasting color

- Thickness and flexibility measurement: precise instruments monitor each batch

Technology and Equipment Advantages

Yudeng introduces international advanced equipment combined with proprietary formulas to achieve high standards in softness, wear resistance, durability, and environmental performance.

This systematic production and strict quality control allow Yudeng to maintain excellent performance and consistency in every meter of PU leather, even at high production volumes.

Advantages of Collaborating with Yudeng and Success Cases

Collaboration Advantages

- Flexible production: supports rapid small batch sampling and stable large-scale production

- Customization services: texture, color, thickness, and function fully customizable

- Technical support: professional guidance from material selection to finished product performance

- International certifications: ISO9001, OEKO-TEX, REACH, RoHS, and GRS

Success Cases

- Footwear brands: supplied high wear-resistant PU leather to domestic sports shoe brands, annual purchase exceeding 50,000 m²

- Bag brands: customized high-end textures for handbags and backpacks exported to Europe and America

- Furniture industry: provided soft and durable PU leather for sofas and chairs, meeting international brand standards

- Home decor and other applications: jewelry packaging, children’s play facilities, protective padding, and medical equipment materials

These cases demonstrate Yudeng’s comprehensive strengths in production capacity, customization service, and customer satisfaction.

| Start Your Order | Email: hello@fjyudeng.com | Number: +86 17746077007 |

With 37 years of industry experience, a complete production system, rich customization capabilities, and strict quality management, Yudeng has become a benchmark in China’s PU synthetic leather manufacturing sector. Whether for high-end footwear, bags, furniture, or apparel, Yudeng can provide full solutions from material selection to functional customization.

For brands and buyers looking for a pu leather manufacturer or pu synthetic leather manufacturers in china, Yudeng is undoubtedly a reliable partner. Contact Yudeng now to obtain samples or inquire about customization services, and experience professional, efficient, and reliable PU synthetic leather solutions.