Yudeng artificial leather manufacturer has been focusing on PU synthetic leather manufacturing for 37 years. It manufactures high-gloss mirror PU leather, which is specially designed for the field of luggage. It takes into account visual impact, environmental protection performance and industrial stability, and provides material upgrade solutions for many brands.

Surface coating technology: UV curing + multi-stage thermal transfer

First, a high-density polyurethane film is coated on the PU surface. After UV light source curing, an extremely smooth micro-mirror layer is formed on the surface. Then the high-gloss film layer is bonded using thermal transfer technology to ensure that the reflectivity reaches 90%±2%, and the gloss is stable, not easy to turn yellow or fog.

Middle layer foaming control: high-density micro-closed-cell foam structure

The foaming core layer adopts a polymer closed-cell structure to ensure that the leather maintains the mirror stiffness while not losing flexibility. It can be directly used for hot pressing and die-cutting of structural packages without breaking or collapsing.

Various backing composite methods: multi-material customization support

Depending on the purpose, we provide a variety of backing options such as non-woven fabrics (150g/m²~250g/m²), knitted fabrics, microfibers, TC fabrics, 3D foam, etc. All backings are processed by a special film layer heat bonding process to ensure that the peel strength is >4.5N/cm, meeting the industry’s high-quality standards

Yudeng adheres to the “material + creativity” dual-engine service concept, providing customers with a one-stop customized service system from design concept to batch implementation, ensuring that the product achieves the best balance between functionality, aesthetics and supply chain efficiency.

We provide the following customization options:

Color customization: support full Pantone color number + special effect customization

The mirror series can be processed with a variety of special effects such as solid color, gradient color, metal reflection, pearl layer, rainbow laser, etc. Some colors support transparent bottom design to enhance the backlight display effect.

Thickness range: 0.6mm~2.0mm freely adjustable

The thickness can be adjusted according to the type of luggage, such as:

Embossed texture selection: In addition to the high-gloss mirror effect, we also provide a variety of embossed versions (such as ice cracks, fantasy carbon fiber, dragon scales, embossed fine lines), taking into account anti-slip, scratch resistance and design aesthetics.

Functional additional processing: Supports additional processes such as antibacterial treatment, UV protection, anti-yellowing, flame retardant treatment (in accordance with EN ISO 6940), empowering the brand with more differentiated selling points.

As the global consumer market’s requirements for environmental protection and sustainability increase, Yudeng has always adhered to the raw material procurement and manufacturing system with environmental protection as the core. All of our glossy mirror PU leather products have obtained the following international certifications to ensure compliance and credibility from “purchasing decision” to “end-use”:

TÜV Rheinland certification: represents that the product has passed independent testing by the German Rhine laboratory in terms of physical performance, stability and environmental indicators;

REACH (EC No. 1907/2006) certification: ensures that the product does not contain more than 190 substances of very high concern (SVHC) and complies with EU chemical regulations;

RoHS directive: strictly controls harmful elements such as lead, mercury, cadmium, and polybrominated biphenyls to meet the standards for export electronic packaging or accessory bags;

OEKO-TEX® Standard 100 Class II certification: suitable for products that are close to the skin, especially suitable for high-end linings and maternal and child products.

Mirror PU leather looks delicate, but it is actually tough. Thanks to Yudeng’s many years of experience in PU material performance adjustment, our products have been widely used in various mid-to-high-end luggage manufacturing projects around the world, including:

Fashion handbags: fast fashion and luxury design that pursue visual impact and brand recognition;

Travel luggage: The mirror layer has good scratch resistance, and B2B customers have successfully applied it to the PC+PU mixed box structure;

Makeup box and beauty tool bag: waterproof and corrosion-resistant, suitable for high-frequency cleaning use scenarios;

Trendy shoulder bags, coin purses, key bags: show youthful and futuristic design language through bright mirrors;

Gift packaging boxes, display bags: give high-end packaging products stronger visual guidance, suitable for brand flash and display purposes.

Yudeng faux leather wholesale suppliers has more than 35 years of experience in PU synthetic leather manufacturing. Its core competitiveness lies not only in “mass production”, but also in “material design capabilities and process reproduction stability”. Our main advantages include:

Complete industrial chain layout: from polyurethane raw material modification, base fabric weaving, coating foaming, mirror transfer, embossing and shaping to post-processing edge banding, all are completed independently in our own workshops;

Monthly production capacity exceeds 5 million meters, and the average daily delivery capacity reaches 20 HQ containers, supporting OEM/ODM order bulk production;

Rich experience in collaboration with international brands: participated in the development of mirror leather luggage projects for many well-known brands in Europe, America and Southeast Asia, and understands the differences in market demand;

Fast sample delivery: conventional sample board making is completed within 3 days, and small batch test materials can be customized within 7 days;

Support third-party factory inspection and quality inspection: long-term cooperation with SGS, ITS, BV and other institutions, supporting the inspection process of customer export project materials.

If you are looking for a “powerful” core material for the upcoming luggage series, welcome to contact Yudeng to start exclusive customization cooperation and work together to create a hot-selling product that is both eye-catching and popular.

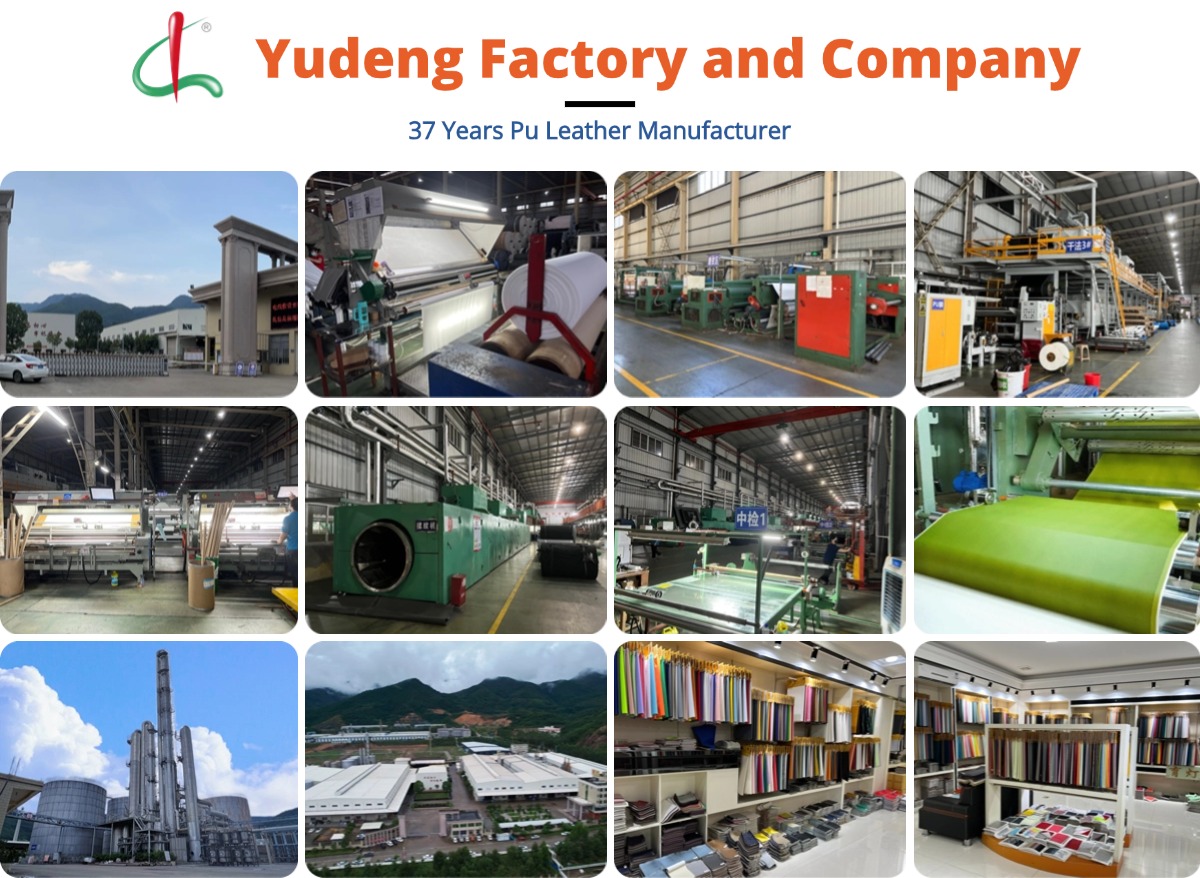

Yudeng Textile is a company focused on the research, development, production, and sales of high-quality polyurethane PU synthetic leather.

With 37 years of industry experience, the introduction of internationally leading production equipment and process technologies, and independently developed innovative formulas, we ensure that our products meet high industry standards in softness, abrasion resistance, weather resistance, and environmental performance.

We are committed to providing customers with eco-friendly, durable, and stylish PU synthetic leather products, widely used in jewelry packaging, footwear materials

Yudeng Textile Factory covers an area of 100,000 square meters, employs 200 staff, and is equipped with 10 production lines, with a daily output of up to 150,000 meters.

We are a 37 years factory manufacturer specializing in the production of mid-to-high-end PU leather

We specialize in the production of high-end PU leather. Our products are green, environmentally friendly and pollution-free, and are suitable for mid-to-high-end products in daily life.

We have 5 lines of dry processing, 3 lines of wet processing, 2 lines of finishing.

And daily output: 150,000 M

Of course, welcome to visit the yudeng pu leather production base

We have about more than 400 textures are avalilable,leather texture can be customized.

For urgent orders, samples can be finished in the fastest 2 days, and Mass production can be produced in 5 days.

Our minimum order quantity is: 300 meters

Yachts and ships, aerospace seats, car seat cushions, home decoration, sofas, medical equipment, sports equipment, children’s amusement park anti-collision bag facilities, etc.