Table of contents

Yudeng Factory Strength and Production Capacity

Yudeng factory covers an area of 100,000 square meters, employs approximately 200 staff, and is equipped with 10 high-efficiency production lines, with a daily output of up to 150,000 meters. Since its establishment in 1988, the company has focused on the R&D and manufacturing of mid-to-high-end PU leather. With 37 years of industry experience, Yudeng has developed a complete production system and rigorous quality management process.

Core Production Equipment and Automation

The Yudeng factory has 5 dry processing lines, 3 wet processing lines, and 2 finishing lines, supporting fully automated PU leather production from base coating to texture embossing. The production process includes:

- Casting the first thin polymer layer

- Attaching the reinforced cotton-polymer layer

- Casting the second foam-like thick polymer layer

- Adding leather-like grooves and gloss

This multi-layer process ensures excellent wear resistance, softness, and resilience while supporting various thickness options (0.3–1.6mm) to meet different product durability and lifespan requirements.

Standardized Production Process and Quality Control

Yudeng implements full-process quality control from raw material procurement to finished product shipment and has obtained ISO 9001 quality management system certification, ensuring that every meter of PU leather meets customer standards. Additionally, the company holds GRS certification, practicing sustainable production. Each batch undergoes strict inspection, including thickness, wear resistance, resilience, and color consistency, guaranteeing customers receive stable and reliable products.

Yudeng’s Expertise in Custom PU Leather Manufacturing

Yudeng’s core strength lies in highly customized capabilities, meeting diverse design needs of customers.

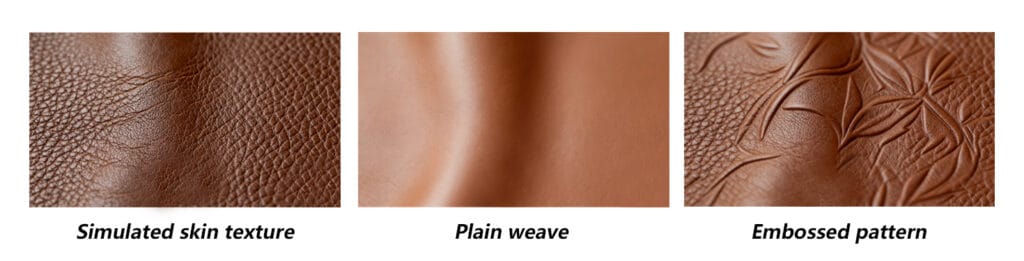

Leather Texture Customization

Yudeng offers over 400 textures, including animal prints, ostrich, giant pebble, pigskin, cantaloupe, stone, woven, crocodile, snake, zebra, sheepskin, lychee, bark, and mirror textures. Customers can customize the surface finish to be smooth and glossy or rough and matte according to their requirements.

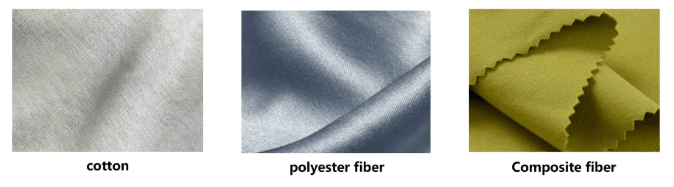

Backing Material Customization

The backing materials of PU leather vary, usually made of fabric or a mix of fabric and other materials. Yudeng provides different backing options according to usage to ensure structure and durability. For example:

- Fashion shoes and bags can use soft and breathable fabric backing

- Furniture and automotive seats can use thick, wear-resistant blended backing

Support for Small and Large Orders

Yudeng can flexibly handle orders of different scales. Samples can be completed in 2 days, and mass production can be delivered in as fast as 5 days, allowing clients to quickly validate designs and proceed to production.

Professional Workflow Example

From sample making to mass production, Yudeng follows a standardized workflow:

- Customers submit texture, color, and thickness requirements

- R&D and design teams produce samples

- Samples are confirmed and small-scale testing is conducted

- Mass production begins with full-process quality monitoring

Material Quality and Sustainability — Yudeng’s Differentiation Advantage

High-Quality Raw Materials

Yudeng selects high-quality polyurethane PU and reliable backing materials, ensuring even, stable, and durable products. High-quality raw materials directly determine the softness, wear resistance, and lifespan of PU leather.

Environmental Protection and International Certifications

Yudeng actively implements green manufacturing, using eco-friendly PU resin and solvent-free production processes. Products have passed REACH, RoHS, OEKO-TEX® certifications. The company is committed to providing safe and sustainable solutions, ensuring pollution-free, environmentally friendly PU leather for mid-to-high-end applications.

Performance Advantages

- High wear resistance and excellent resilience

- Water-resistant, scratch-resistant, and weather-resistant

- Wide thickness options (0.3–1.6mm) to meet different usage needs

Sustainable Development Initiatives

The company reduces carbon footprint by recycling and reusing production waste, optimizing energy use, and developing low-carbon PU formulas, balancing environmental friendliness and high performance.

Yudeng Custom PU Leather Applications and Industry Solutions

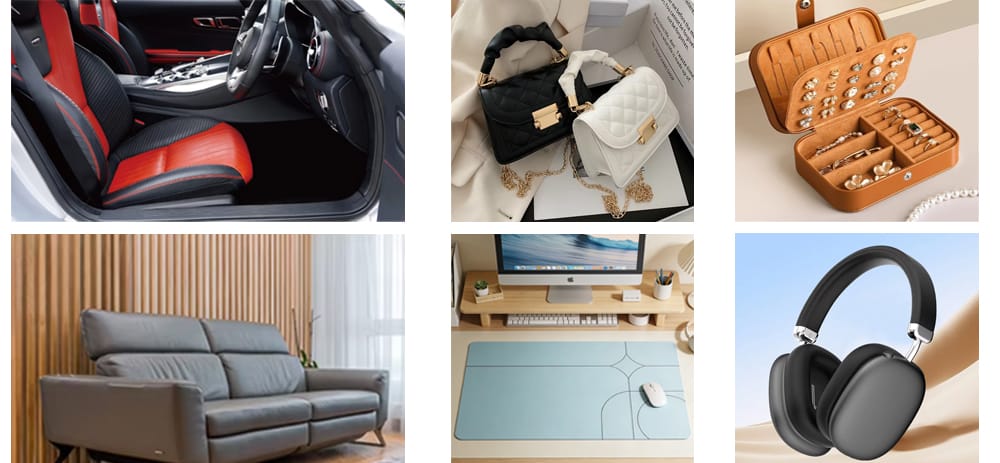

- Fashion and Accessories

PU leather is widely used in shoes, bags, and apparel. Yudeng offers multiple texture and color options, allowing designers to achieve personalized creativity while ensuring durability and comfortable touch, suitable for high-end fashion products. - Furniture and Automotive Interiors

In sofas, chairs, automotive seats, and dashboards, Yudeng PU leather balances aesthetics and durability. Its thick backing and wear-resistant, UV-resistant surface treatment ensure long-term use with stable performance. - Creative Products and Electronics Accessories

PU leather is widely used in jewelry box leather, bracelets, and notebook covers. Yudeng products provide fine textures and premium hand-feel, enhancing product quality while meeting protection and durability needs.

Industry Customization Solutions

For different applications, Yudeng provides professional advice:

- High-wear scenarios should choose reinforced backing and thickness

- Fashion accessories prioritize thin and soft backing

- Grooves, gloss, and surface textures can be adjusted according to customer requirements

Yudeng’s PU Leather Customization Advantages and Purchasing Guide

As an experienced pu leather supplier and pu leather company, Yudeng offers significant advantages in PU leather customization:

- Texture customization: supports simulated leather, embossed, special patterns, and personalized designs, meeting the needs of luxury furniture, bags, automotive, and apparel industries.

- Substrate customization: allows selection of polyester, cotton, blended, or non-woven substrates, balancing wear resistance, softness, and cost-effectiveness.

- Flexible production capability: offers small-batch samples for testing performance and appearance, while supporting large-scale production to ensure timely delivery.

Practical steps:

- Define requirements: determine application scenario, usage frequency, durability, and aesthetic needs.

- Select surface and substrate combination: choose PU coating thickness, texture, and substrate type according to usage and touch requirements.

- Sample production and performance testing: evaluate wear resistance, waterproofing, and softness to ensure compliance with project standards.

- Mass production and delivery: after sample confirmation, proceed with production, Yudeng ensures consistent quality and stable output.

Advantages of choosing Yudeng:

- Years of PU leather manufacturing experience, mature and reliable technology

- Strict quality control system, ensuring stability and consistency of each batch

- Flexible customization capabilities to meet diverse industry needs

Collaborating with a professional pu material supplier and pu leather company enables users to obtain high-quality PU leather, reduce design testing and procurement costs, and improve project efficiency.

| Start Your order | Email: hello@fjyudeng.com | Number:+86 17746077007 |

As a professional factory with 37 years of PU leather manufacturing experience, Yudeng, with advanced equipment, rich craftsmanship, excellent quality management, and flexible customization services, has become a leading supplier in the mid-to-high-end PU leather market in 2025. Whether for shoes, bags, home sofas, automotive interiors, or creative electronics accessories, Yudeng provides safe, durable, eco-friendly, and high-quality PU leather solutions.

Choosing Yudeng means selecting not only premium products but also a reliable long-term partner. Contact Yudeng today to obtain samples or custom solutions, making your products more competitive.