Table of contents

- Understanding PU Leather and Its Core Applications

- Key PU Leather Textures: Embossed, Matte, and Glossy

- Custom PU Leather Finishes: From Design Concept to Mass Production

- How to Choose the Right PU Leather Texture for Different Projects

- Yudeng’s Expertise in Custom PU Leather Texture and Base Material Design

Understanding PU Leather and Its Core Applications

Basic Definition and Structure of PU Leather

PU leather (Polyurethane Leather) is a type of synthetic leather material made by coating a fabric substrate with polyurethane resin. The typical structure consists of two parts:

- Top coating: Functional PU layer that determines appearance, touch, and wear resistance

- Bottom substrate: Fabric base that directly affects overall strength, flexibility, and durability

Key Differences Between PU Leather and Genuine Leather

- Color stability: PU leather achieves batch consistency, whereas genuine leather varies depending on source and treatment methods

- Controllability: PU leather allows precise control of texture, thickness, and surface effects through engineering processes

- Reason for brand choice: Many brands select professional pu leather manufacturer to ensure stable product appearance and performance

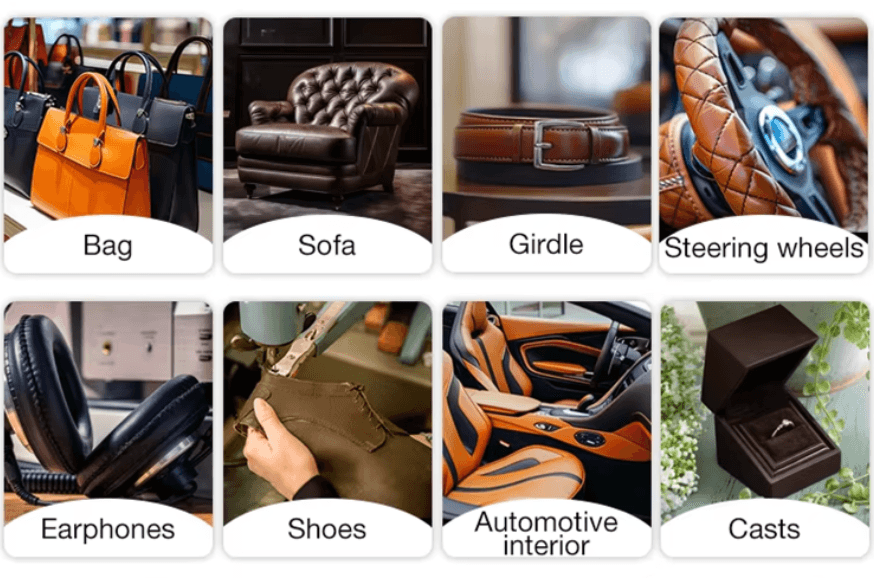

Primary Application Areas of PU Leather

PU leather is widely used in furniture, footwear, bags, apparel, and automotive interiors.

- In furniture, it is wear-resistant and easy to clean, suitable for sofas and chairs.

- In footwear and bags, rich textures and colors meet diverse design requirements.

- In apparel, it is lightweight and easy to process, commonly used for jackets, gloves, and outerwear.

- In automotive interiors, PU leather provides durability and premium touch for seats and dashboards.

In all cases, PU leather emphasizes consistent appearance, durability, and long-term performance.

Key PU Leather Textures: Embossed, Matte, and Glossy

The texture of PU leather determines its visual effect and tactile feel. Different textures are formed through distinct manufacturing processes. Below is a detailed analysis of the three main textures:

Embossed PU Leather: Texture and Production Technology

- Concept and Usage: Embossed PU leather creates a tactile surface, enhancing visual layers and touch experience. It can mimic natural leather textures such as crocodile or snake skin and is widely used in footwear, handbags, furniture, and automotive interiors.

- Common Embossed Types:

- Animal patterns: Crocodile, snake, commonly used in premium shoes and bags

- Geometric patterns: Lines, diamonds, squares, offering modern aesthetics

- Checkered/Woven patterns: Rich textures suitable for bags and accessories

- Production Methods:

- Roller embossing: Imprinting patterns on semi-cured surface using textured rollers, ideal for mass production

- Heat transfer film: Transferring patterned film via heat press, allowing complex designs

- Laser embossing: Laser ablation or engraving for fine patterns, suitable for small batch customization

Matte PU Leather: Features and Advantages

- Definition and Visual Effect: Matte PU leather has low gloss and weak reflection, giving a soft and modern visual feel that emphasizes material texture

- Characteristics:

- Light is diffusely reflected, providing uniform appearance

- Easy to dye and adjust color, presenting rich hues

- Surface resists fingerprints and minor scratches

- Production Methods:

- Use of matte polyurethane resin to control gloss

- Spray or multi-layer thin coating to create microstructure for diffuse reflection

- Typical Applications: High-end furniture (sofas, chairs), handbags and bags, automotive seats and dashboards

Glossy PU Leather: Gloss Finish and Care

- Visual Impact: Glossy PU leather provides a high-gloss surface that creates a strong visual effect, emphasizing fashion and decorative appeal

- Characteristics:

- Smooth surface with high gloss

- Saturated colors with noticeable visual layers

- Easy to clean surface stains

- Production Methods:

- Precise control of coating thickness to achieve uniform gloss

- High-transparency PU resin combined with polishing process

- Optional transparent protective layer to improve durability

- Typical Applications: Footwear, handbags, and small accessories emphasizing visual effect and decoration

Custom PU Leather Finishes: From Design Concept to Mass Production

Value of Customization in PU Leather

With increasing demand for brand differentiation and uniqueness, standardized PU leather can no longer meet market requirements. Customization applies not only to appearance design but also to performance, structure, and long-term stability. By customizing PU leather, brands can achieve exclusive textures, colors, and tactile experiences while ensuring consistent quality over time.

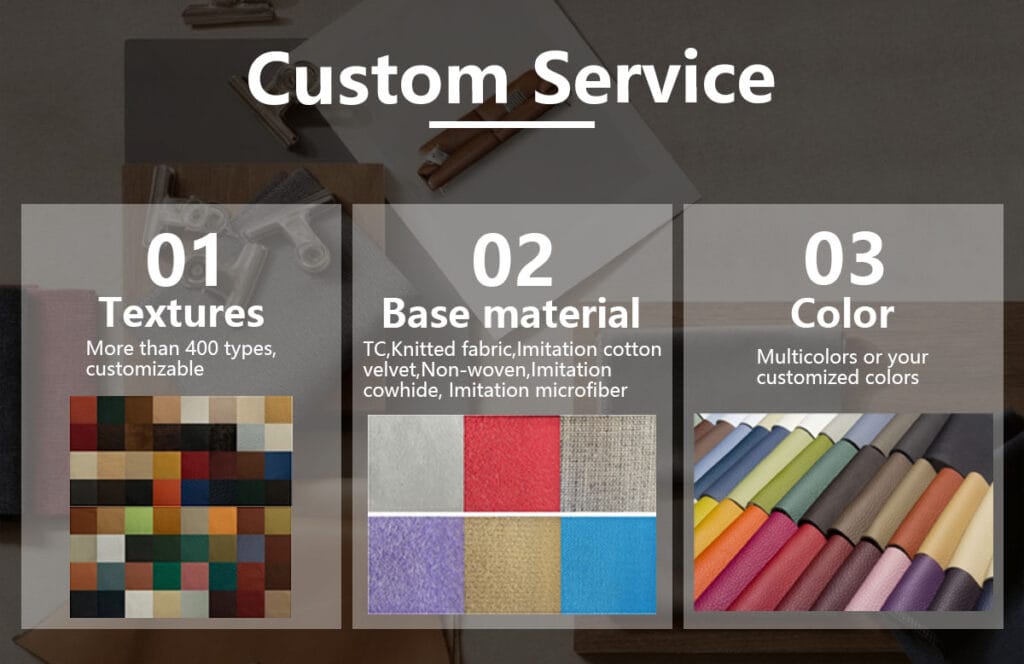

Core Elements That Can Be Customized

Key customizable elements of PU leather include:

- Texture style: Embossed, plain, or innovative patterns

- Surface finish: Matte or glossy, adjusting gloss according to design style

- Substrate structure: Different fabric bases affect flexibility, wear resistance, and touch

Each element directly affects the final product’s visual appeal, tactile feel, and performance, requiring careful consideration during the design stage.

Standard Process for Custom PU Leather

Professional pu leather fabric manufacturers usually follow this process:

- Application requirement analysis: Develop customization plan based on product use and design requirements

- Texture design and substrate matching: Select the most suitable surface texture and base structure

- Sample testing: Produce samples and perform performance tests including wear resistance, color fastness, and touch

- Mass production confirmation: Ensure production process is stable and the final product meets design objectives

Importance of Sample and Testing

Sample evaluation not only confirms the visual design but also verifies wear resistance, colorfastness, and structural stability. Skipping this step can result in cracks, color deviation, or inconsistent texture in mass production, affecting brand reputation and user experience.

Yudeng’s Custom Services

Yudeng, as a professional pu leather manufacturer, provides comprehensive PU leather customization services, including:

- Texture customization: Supports embossed, plain, matte, glossy, and special textures, simulating natural leather or innovative designs

- Substrate customization: Offers polyester, cotton, or blended fabrics to match flexibility, durability, and tactile feel requirements

- Thickness and coating adjustment: Customize PU leather thickness and coating ratio based on product application

- Color and finish: Supports solid color, gradient, metallic, or pearlescent effects, ensuring minimal batch color variation

- Special functionality customization: Such as waterproof, stain-resistant, flame-retardant, or scratch-resistant coatings

Yudeng’s custom services cover the entire process from design, sample production, to mass production control, ensuring clients receive PU leather products that meet visual, tactile, and performance standards.

How to Choose the Right PU Leather Texture for Different Projects

Choosing PU leather texture requires comprehensive consideration of project type, functional needs, and visual effects:

- Furniture projects: Choose wear-resistant, fine-textured matte PU leather to reduce reflection and enhance comfort; proper thickness increases durability

- Footwear and bags: Embossed and glossy PU leather enhances visual layers and brand design sense

- Apparel and accessories: Lightweight plain or matte PU leather suits jackets, gloves, and small accessories

- Automotive interiors: Matte PU leather for seats and dashboards, glossy PU leather for decorative small parts

- Custom creative products: Select special textures and functional coatings like waterproof, stain-resistant, or pearlescent effects to achieve differentiated designs

Yudeng’s Expertise in Custom PU Leather Texture and Base Material Design

As a pu leather manufacturer with 38 years of experience, Yudeng, established in 1988, has focused on high-quality polyurethane PU leather R&D, production, and sales. Leveraging extensive industry experience, advanced production equipment, and self-developed innovative formulations, Yudeng meets diverse customer demands for PU leather textures, substrates, and performance.

Comprehensive Production Capability

- Factory scale: Yudeng Textile Factory occupies 100,000 m² with 200 employees and advanced equipment

- Production lines: 10 lines (5 dry, 3 wet, 2 finishing), supporting large-scale and customized production

- Daily output: 150,000 meters, sample ready in 2 days, mass production in 5 days

Rich Texture Selection and Customization

- Over 400 standard textures including animal, woven, and stone patterns

- Custom textures: matte, glossy, or innovative designs

- Surface finishes: matte, glossy, pearlescent, metallic, mirror effects

Diverse Substrate Options and Thickness Adjustment

- Substrate types: fabric or blended materials, balancing flexibility, wear resistance, and tactile feel

- Thickness range: 0.3–1.6 mm

- Structural support: substrate provides stability combined with PU coating for comfort and durability

Strict Quality Control and Environmental Standards

- ISO 9001 quality management system certification

- REACH, RoHS, OEKO-TEX® international environmental certifications

- Full-process quality control ensures every meter of PU leather meets client standards

With 38 years of experience, professional expertise, and full customization capability, Yudeng is a leading domestic pu leather manufacturer and a trusted partner for brands and designers.

| Start Your order | Email: hello@fjyudeng.com | Number:+86 17746077007 |

PU leather, as a high-performance synthetic leather material, offers rich textures, diverse surface effects, and customizable substrates to meet design and functional requirements across projects. From embossed, matte to glossy finishes, each texture provides unique visual appeal and tactile experience, while customization further helps brands create exclusive products.

With 38 years of industry experience, Yudeng has extensive professional capability in PU leather texture, substrate, and performance customization, offering end-to-end support from design samples and testing to mass production. Every product achieves high standards in appearance, touch, and functionality. Whether for furniture, footwear, bags, or creative products, choosing a professional pu leather manufacturer ensures designs are realized efficiently and reliably.

Explore the diversity and customization potential of PU leather, creating products that combine beauty and durability while meeting brand vision and user experience standards.