Table of contents

Understanding PU Leather: Materials, Types, and Applications

- Basic Structure of PU Leather

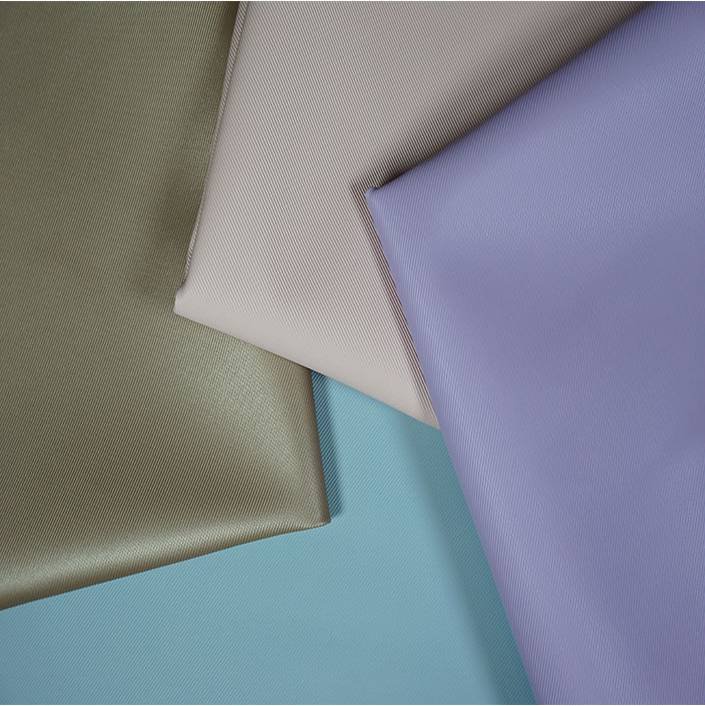

PU leather consists of a surface polyurethane layer and a substrate (base material). The polyurethane layer determines the leather’s gloss, feel, texture effect, as well as wear resistance, water resistance, and durability. The substrate provides structural support, affecting flexibility and overall stability, commonly made from non-woven fabric, cotton fabric, or polyester fabric. - Types and Textures of PU Leather

- Embossed PU: Formed under high temperature and pressure to create fixed textures, suitable for shoe uppers and furniture surfaces.

- Roll-pressed PU: Suitable for large-scale production, with uniform textures and stable visual effects.

- Micro-perforated PU: Improves breathability, commonly used in furniture and seating.

- Laser-textured PU: Simulates complex natural leather patterns, suitable for high-end automotive interiors and luxury products.

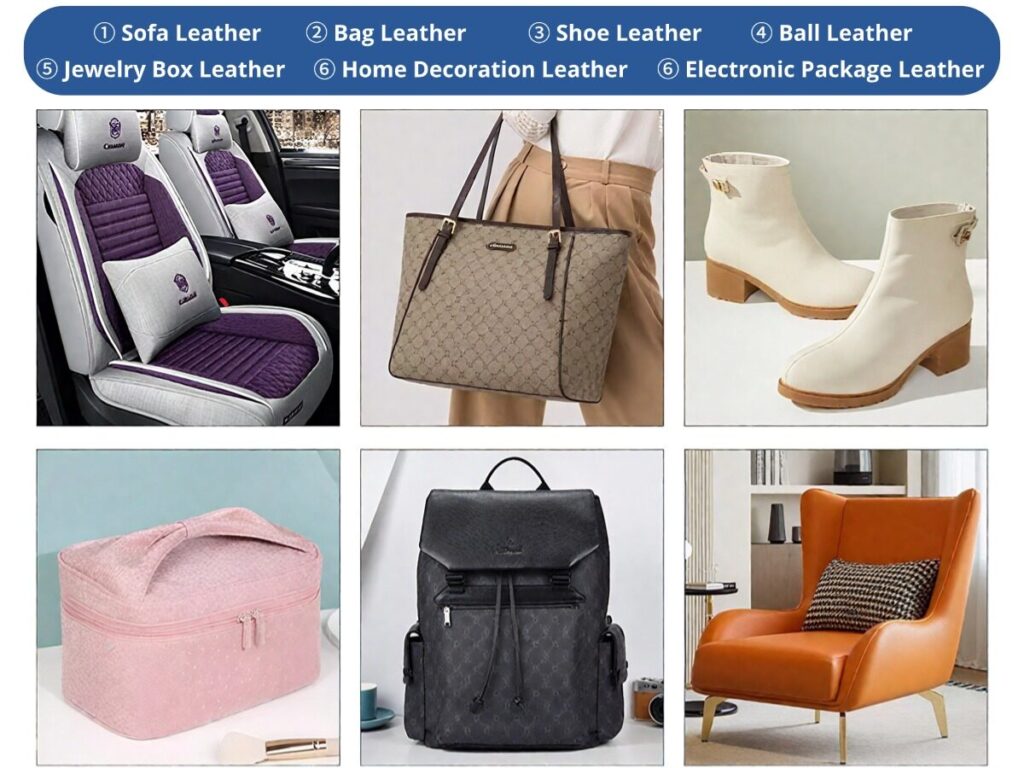

- Application Scenarios

- Footwear: Sports shoes, casual shoes, and high-end shoe uppers.

- Furniture: Sofas, seats, and office furniture.

- Automotive Interiors: Seat covers, armrests, and dashboard coverings.

- Fashion Accessories: Handbags, luggage, jewelry boxes, and small accessories.

Why Choose Yudeng: Advantages of a Top PU Leather Manufacturer

Yudeng, established in 1988, has 37 years of high-quality PU leather production experience and is one of China’s leading pu leather factory. Its advantages are mainly reflected in the following aspects:

- Factory Qualifications and Certifications: Yudeng has passed ISO9001 quality management system certification and obtained OEKO-TEX, REACH, and RoHS environmental certifications. Additionally, the factory holds GRS certification to ensure sustainable and environmentally responsible production. These certifications reflect Yudeng’s adherence to international standards in product quality, raw material selection, and eco-friendly manufacturing.

- Production Capacity and Equipment: Yudeng’s textile factory covers 100,000 square meters, employs 200 staff, and operates 10 production lines, including dry processing, wet processing, and finishing lines. Daily output reaches up to 150,000 meters, reliably meeting the needs of both small brands and large-scale orders. Advanced equipment such as coating machines, embossing machines, texture rollers, and precision testing instruments ensure production efficiency and product consistency.

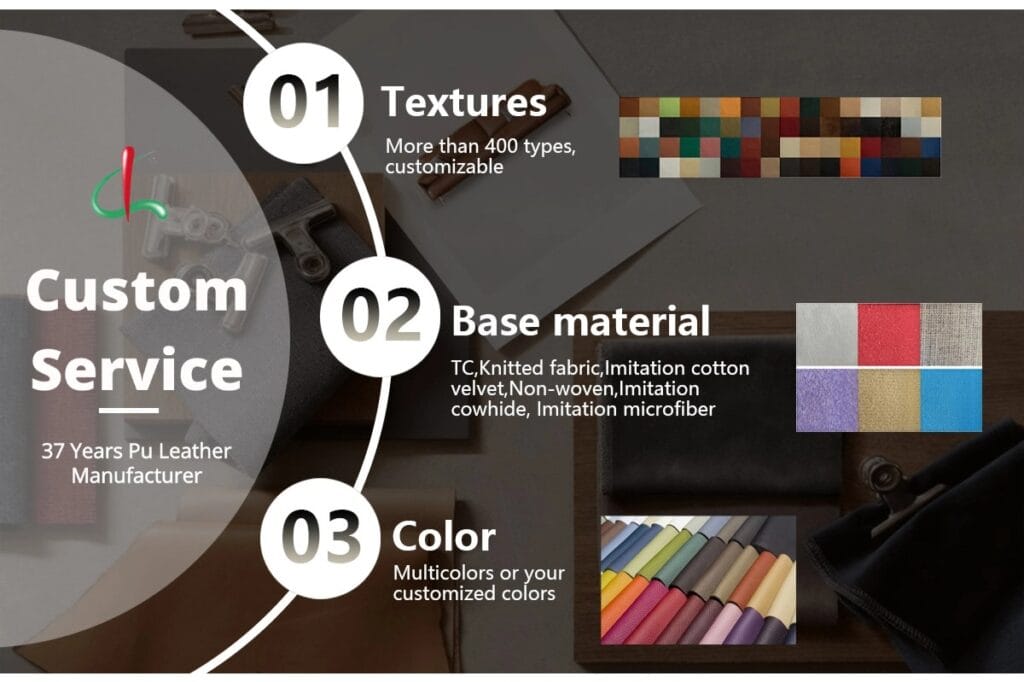

- Extensive Texture Selection and Customization: Yudeng offers over 400 PU leather textures, including animal patterns, ostrich patterns, crocodile patterns, snake patterns, zebra patterns, and lychee textures. Customers can customize texture, color, and thickness (0.3–1.6mm) according to requirements, making the leather suitable for footwear, luggage, furniture, and automotive seats.

- Fast Production and Flexible Delivery: Yudeng can complete samples within 2 days and start mass production in 5 days. The minimum order quantity is only 300 meters, accommodating both small trial runs and large-scale production. This flexibility ensures efficient supply chain operations and reliable support for urgent projects.

- Production Stability and Process Advantages: Yudeng strictly controls process parameters to ensure each batch of PU leather has consistent texture, thickness, color, and feel. Through advanced coating, embossing, and curing processes, the products offer excellent wear resistance, elasticity, and eco-friendliness. Yudeng also provides one-stop customization services from texture design and substrate selection to finished product processing, ensuring high-efficiency and reliable production.

Yudeng PU Leather Customization

Yudeng offers comprehensive PU leather customization services, catering to customer needs in texture, color, thickness, and substrate. Whether for small sample orders or large-scale production, Yudeng’s standardized and flexible approach helps clients achieve their ideal product.

- Customization Content

- Texture Selection: Yudeng offers over 400 existing textures, including animal patterns, crocodile, snake, zebra, and lychee textures. Customers can select existing textures or provide design drafts for exclusive customization.

- Color Customization: Multiple standard colors are available, with support for custom brand colors to ensure consistency with brand identity.

- Thickness and Substrate: Appropriate thickness (0.3–1.6mm) and base materials, such as non-woven fabric, cotton, or polyester, are chosen according to application requirements to achieve desired softness and support.

- Finished Appearance: Options include glossy, matte, embossed, or mirror-like finishes to suit footwear, luggage, furniture, automotive seats, and more.

- Customization Process

- Requirement Communication: Clients clarify product purpose, texture, color, and thickness.

- Sample Production: Small batches are produced according to customer specifications for approval.

- Client Approval: Once the sample is confirmed, mass production parameters are finalized.

- Mass Production: Bulk production is carried out based on approved samples and parameters to ensure consistency.

- Quality Inspection and Delivery: Completed products undergo strict quality control before packaging and shipment to ensure compliance with client requirements.

- Customization Advantages

- Fast Response: Samples can be completed within 2 days, mass production within 5 days.

- Flexible Adjustments: Texture and color can be modified based on client feedback to meet final expectations.

- High Reliability: Each batch undergoes strict quality inspection to guarantee stable results and minimize waste.

Applications and Multi-Industry Advantages of PU Leather

Yudeng’s PU leather is widely used across multiple industries due to its quality, durability, and customization capabilities:

- Footwear: Suitable for sports shoes, casual shoes, and high-end uppers, providing wear resistance, softness, and high elasticity while meeting design-specific texture and color requirements.

- Luggage and Accessories: Used in handbags, wallets, jewelry boxes, and small accessories, offering diverse textures and fine surface treatment that balance aesthetics and practicality.

- Furniture and Home Decoration: Ideal for sofas, chairs, and office furniture, delivering soft and comfortable feel, easy maintenance, and wear resistance suitable for daily use.

- Automotive Interiors: Applicable to seats, armrests, and dashboards, providing durability, stain resistance, and easy cleaning, while supporting high-end texture and color customization.

- Special Industry Applications: PU leather is also used in medical equipment, child playground safety pads, and aerospace seating, demonstrating durability, safety, and eco-friendly characteristics.

Common Issues in PU Leather Manufacturing and Yudeng’s Solutions

During PU leather production, certain challenges may affect product quality and consistency. Yudeng, with 37 years of manufacturing experience and mature production systems, effectively addresses the following:

- Uneven or Defective Textures: Texture inconsistencies or defects may occur in some PU leather production. Yudeng ensures clear, uniform textures for each batch through strict process control and equipment adjustment.

- Color Deviation: Color differences between batches can occur. Yudeng uses advanced color management systems and standardized color-matching processes to maintain consistent colors that meet brand requirements.

- Thickness or Flexibility Instability: Variations in thickness or flexibility may affect product usability. Yudeng ensures consistent thickness and flexibility through careful material selection and production monitoring, suitable for footwear, luggage, furniture, and automotive seats.

- Environmental and Safety Concerns: PU leather may carry risks of solvent residue or non-eco-friendly materials. Yudeng uses eco-friendly PU resins and solvent-free processes, complying with REACH, RoHS, and OEKO-TEX standards to ensure safe and sustainable products.

- Consistency in Mass Production: Maintaining uniform quality in large-scale production is challenging. Yudeng uses automated production equipment, standardized processes, and strict quality inspections to ensure stability and reliability across batches.

| Start Your order | Email: hello@fjyudeng.com | Number:+86 17746077007 |

As a pu leather manufacturer with 37 years of experience, Yudeng not only leads the industry in production scale, equipment, texture customization, and environmental certification but also accumulates rich expertise in PU leather manufacturing, customization, and supply chain management. Whether for footwear, luggage, furniture, automotive interiors, or specialized applications, Yudeng provides high-quality, eco-friendly, and sustainable PU leather products. Choosing Yudeng means partnering with a reliable, flexible, and efficient supplier, ensuring stable, premium materials for your brand.