Table of contents

Basics of PU Leather: Understanding This Material

PU leather, also known as Polyurethane Leather, is a synthetic leather material made by combining a polyurethane (PU) surface coating with a textile or other backing material. It is produced through coating, embossing, and impregnation processes, ensuring the PU layer bonds firmly with the backing material to create a leather-like appearance and texture. PU leather differs from PVC synthetic leather by being softer, more breathable, environmentally friendly, and highly customizable, making it widely used in furniture, apparel, footwear, automotive interiors, and various accessories.

The structure of PU leather typically includes three layers:

- Surface PU coating: Provides waterproof, stain-resistant, abrasion-resistant, and decorative properties. Different embossing techniques create various textures.

- Middle functional layer: Enhances flexibility, abrasion resistance, and tear resistance.

- Backing layer: Usually polyester fabric, cotton, or microfiber, providing support and stability.

Common PU leather types include grain, matte, smooth, and embossed animal textures. Designers can select textures according to product needs, creating diverse visual effects. Thickness, backing type, and surface finishing all affect feel and durability, so understanding these factors is essential when sourcing or customizing PU leather.

Compared to genuine leather, PU leather does not rely on animal resources and avoids natural defects, color variations, and odors. Compared with traditional PVC leather, PU leather is softer, more breathable, and environmentally friendlier.

Advantages of PU Leather

In recent years, PU leather has become a preferred material in furniture, apparel, footwear, and automotive interiors due to its advantages in cost, performance, and sustainability. Key benefits include:

- High Cost-Effectiveness: PU leather is made from polyurethane and textile backing, offering production costs far lower than genuine leather. Market data shows that pu leather price is generally only 20%–30% of real leather while still achieving a leather-like look and feel. This makes PU leather ideal for large-scale furniture coverings, shoes, bags, and accessories, providing high-quality appearance at a lower cost.

- Easy Cleaning and Maintenance: PU leather surfaces are non-porous and resistant to water and everyday stains. Unlike genuine leather, which requires oils and regular care, PU leather can be cleaned with a damp cloth to remove dust, liquids, or minor stains. This makes it highly practical for office chairs, home sofas, and automotive seating.

- Durability: While the lifespan of PU leather may not match premium real leather, it offers excellent wear resistance and is less prone to fading or deformation. Modern PU leather is treated with multi-layer coating and embossing processes, maintaining its appearance for years. For frequently used products, PU leather with thickness ≥1.0 mm improves durability further.

- High Customizability and Versatility: PU leather is highly moldable and can be customized through embossing and coloring to achieve various textures and colors, such as cowhide, crocodile, or snake patterns. Designers and brands can select the suitable texture, color, and thickness to match product positioning, enabling highly personalized designs.

- Eco-Friendliness and Sustainability: PU leather does not require animal hides, offering environmental and ethical advantages. Modern production uses low-VOC formulations and may incorporate renewable fibers or eco-friendly backings, reducing resource consumption and pollution compared with genuine leather. For companies and individuals prioritizing sustainable design, PU leather is a top choice.

Disadvantages of PU Leather

Before choosing PU leather as a genuine leather alternative, its limitations must be considered.

Firstly, PU leather is less breathable than real leather, which can cause discomfort during long periods of wear or use in hot or humid environments. Its dense structure restricts airflow and moisture evaporation, so clothing, footwear, or seating may feel warm without additional ventilation or lining.

Secondly, PU leather lacks the natural texture and feel of genuine leather. While embossing and coloring can mimic cowhide, crocodile, or other animal textures, the tactile experience remains synthetic and lacks the unique softness and character of real leather. High-end products seeking natural feel may not be fully satisfied with PU leather.

Additionally, new PU leather may emit slight plastic or chemical odors. Although these dissipate over time, they may affect initial user experience. Environmental factors such as heat, sunlight, and humidity can also accelerate aging, fading, or minor cracking, potentially reducing longevity.

In summary, PU leather offers an affordable, eco-friendly, and customizable alternative, but it does not match real leather in breathability, natural feel, or long-term durability. When selecting PU leather, users should assess actual usage conditions to choose the appropriate type and process.

PU Leather Manufacturing and Customization

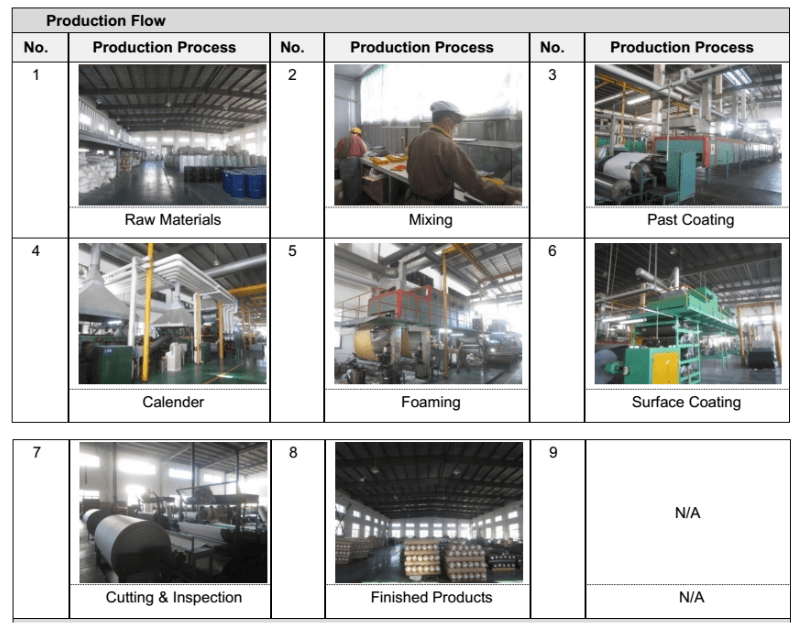

1. Production Process

The production of PU leather is precise and controlled, typically involving:

- Backing preparation: Selecting the appropriate backing such as polyester fabric, cotton, or microfiber to provide support and stability.

- Coating/impregnation: Evenly applying PU solution to the backing using coating or immersion techniques to ensure strong adhesion.

- Embossing/texture processing: Using molds to create various textures, including grain, smooth, or animal patterns, for versatile designs.

- Drying and curing: Controlling temperature and time to ensure PU layer fully bonds to the backing, enhancing durability.

- Surface finishing: Applying gloss, waterproofing, or scratch-resistant treatments based on product requirements.

2. Customization Process

The customization workflow includes:

- Defining usage and design needs: Determining thickness, texture, color, and softness based on product type.

- Selecting backing and process: Choosing the optimal backing and coating process to achieve the desired effect.

- Sample approval: Creating prototypes for texture, color, and feel confirmation before mass production.

- Mass production and quality control: Conducting strict testing including abrasion, tensile, and lightfastness tests to ensure product consistency.

Why Choose Yudeng PU Leather?

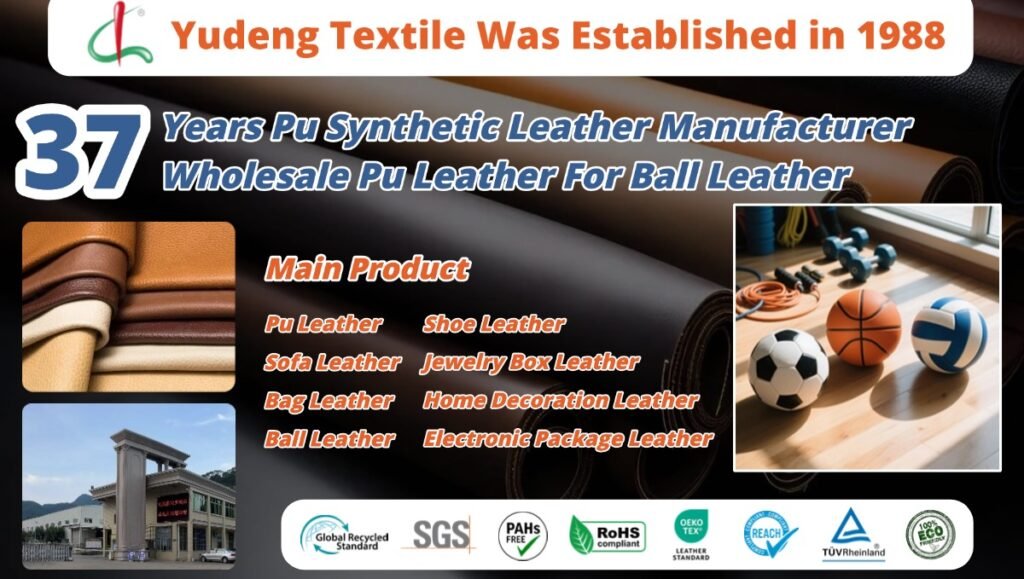

As a leading high-quality PU leather manufacturer in China, Yudeng (Yudeng Textile) has 37 years of R&D and production experience, offering environmentally friendly, durable, and highly customizable PU leather for global clients.

Core Advantages:

- Robust Production Capacity & Advanced Equipment: Yudeng operates a 100,000 m² factory with 200 employees and 10 production lines (5 dry processing, 3 wet processing, 2 finishing lines), achieving a daily output of 150,000 meters. Proprietary formulations ensure each meter meets high standards for softness, abrasion resistance, and weather durability.

- Strict Quality & Environmental Certifications: Products are ISO 9001 certified and comply with REACH, RoHS, and OEKO-TEX® standards, ensuring international environmental and safety compliance.

- Highly Customizable Textures & Thickness: Over 400 textures are available, including smooth, matte, grain, animal patterns, crocodile, snake, zebra, and more. Thickness ranges from 0.3–1.6 mm, with backing options of fabric or fabric composites to provide support and stability.

- Efficient Production & Flexible Delivery: Urgent sample orders can be completed in 2 days, with mass production ready in 5 days. Minimum order quantity is 300 meters, supporting both small and large-scale projects.

- Wide Application & Client Recognition: Yudeng PU leather is widely used in home decor, sofas, yachts, aircraft seating, automotive interiors, footwear, bags, and children’s playground equipment. With rigorous quality control and client-oriented service, Yudeng has served hundreds of domestic and international brands, maintaining over 95% customer satisfaction.

Applications of PU Leather

- Furniture: Used for sofas, chairs, and office seating; waterproof, stain-resistant, and easy to clean. Thickness ≥1.0 mm suitable for high-frequency use.

- Apparel: Suited for jackets, pants, and bags; embossing and dyeing can mimic real leather while remaining cost-effective.

- Footwear: Common in sports, casual, and boots; flexible and finely embossed PU leather ensures comfort and durability.

- Automotive Interiors: Seats, steering wheels, and door panels; low VOC, lightfast, and heat-resistant PU leather balances aesthetics with practicality.

- Accessories: Wallets, handbags, phone cases; customizable textures and colors enable attractive and economical designs.

| Start Your order | Email: hello@fjyudeng.com | Number:+86 17746077007 |

PU leather combines cost-effectiveness, customizability, and eco-friendliness, making it widely used in furniture, apparel, footwear, automotive interiors, and accessories. Although its durability and natural feel are lower than genuine leather, selecting high-quality PU leather from an experienced pu leather factory, especially a professional manufacturer like Yudeng, ensures long-lasting performance. Understanding PU leather’s advantages, disadvantages, and applications allows designers and consumers to make informed decisions, achieving both affordability and aesthetic appeal.