Table of contents

What Is PU Leather?

PU leather, also known as polyurethane leather, is a synthetic material designed to mimic the appearance and texture of genuine leather. It has become a widely used material across multiple industries due to its versatility and performance characteristics.

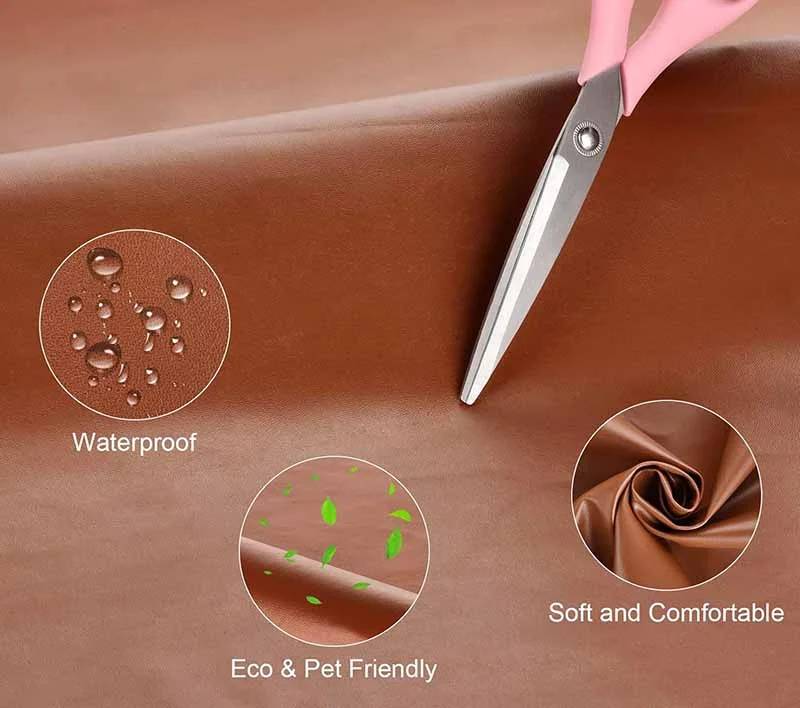

PU leather offers several key advantages:

- Softness and Flexibility: PU leather is soft and elastic, allowing it to be shaped into various forms for furniture, bags, and automotive interiors. This flexibility meets diverse design and manufacturing needs.

- Water Resistance: The surface of PU leather is coated with polyurethane, providing a degree of water resistance. It is suitable for items exposed to moisture, such as furniture and outdoor equipment. However, prolonged exposure may allow water penetration.

- Durability: PU leather resists cracking, tearing, and fading, maintaining its appearance over time. While extreme conditions may cause wear, it is generally durable for furniture and accessories under normal use.

- Fire Resistance: Certain PU leather products meet fire safety standards, enhancing safety for furniture and automotive interiors, especially in regulated commercial applications.

- Hydrolysis Resistance: PU leather maintains structural stability over time, reducing peeling and cracking even under high-stress conditions.

- Affordability and Ethical Choice: PU leather is less expensive than genuine leather and is suitable for vegan consumers, appealing to environmentally conscious and ethically minded buyers.

PU Leather Manufacturing Process

PU leather is produced using two main techniques: dry method and wet method. Both methods combine polyurethane with fabric backings to achieve the desired performance and appearance.

Dry Method

- Coating on Release Paper: Polyurethane resin is applied on release paper in one or two layers.

- Drying: The coated material is baked to remove solvents, forming a thin PU film.

- Adhesion: An adhesive layer is applied, and the PU film is bonded to the fabric backing. The release paper is then removed.

- Fabric Backing: Polyester, cotton, rayon, or nylon backings are used to provide strength and durability.

- Curing: The coated material is cured in a controlled environment to stabilize the PU layer.

- Surface Finishing: The PU leather can be embossed, printed, or treated to achieve the final texture and appearance.

Wet Method

- Coating Nonwoven Fabric: Polyurethane solution is applied onto nonwoven fabric.

- Gel Formation: Immersing the fabric in DMF (N,N-dimethylformamide) causes the PU to gel and solidify.

- Micropores: Micropores form during PU shrinkage, allowing breathability and moisture regulation.

- Washing and Drying: Residual DMF is removed, and the material is dried.

- Final Coating: A last PU layer is applied using release paper and baked to achieve the finished product.

The PU leather may undergo additional embossing or surface treatments to replicate natural leather textures, enhancing both appearance and performance.

PU Leather Applications Across Industries

PU leather is widely applied in many sectors due to its versatility. Key industry applications include:

- Furniture: Used for sofas, chairs, and office seating, offering durability, comfort, and easy maintenance.

- Footwear: Applied in shoes and boots where flexibility, comfort, and wear resistance are critical.

- Bags and Luggage: Provides stylish, durable surfaces for handbags, backpacks, and travel bags.

- Automotive Interiors: Seats, dashboards, and door panels benefit from PU leather’s water resistance and aesthetic appeal.

- Home Decor and Accessories: Cushions, wall panels, jewelry boxes, and decorative surfaces.

- Specialized Equipment: Medical devices, sports gear, and protective surfaces in children’s play areas or industrial applications.

Comparison with Other Synthetic Leathers

When selecting synthetic leather, PU leather is often compared with PVC leather, both of which serve as alternatives to genuine leather.

Comfort and Breathability

- PU Leather: Offers better breathability, making it suitable for clothing, shoes, and seating where comfort is crucial.

- PVC Leather: Has limited breathability, potentially causing discomfort during prolonged wear.

Appearance and Texture

- PU Leather: Feels softer and more natural, closely resembling real leather. Its uniform texture and flexibility enhance product aesthetics.

- PVC Leather: Appears glossier but less natural. Durable but may look artificial for high-end products.

Environmental Impact

- PU Leather: Generally more eco-friendly, free of harmful chlorides, and reduces carbon emissions.

- PVC Leather: Produces chlorides during manufacturing and disposal, which can harm the environment.

Durability and Wear Resistance

- PU Leather: Soft and elastic but may develop cracks or peeling over time under frequent use.

- PVC Leather: Tougher and more abrasion-resistant but less flexible than PU leather.

Cost and Affordability

- PU Leather: Higher production cost than PVC but cheaper than genuine leather, offering a balance between quality and price.

- PVC Leather: Lower cost, suitable for applications prioritizing durability over aesthetics.

PU Leather Core Advantages and Yudeng’s Manufacturing Strength

PU leather’s performance advantages make it a key material in modern furniture, footwear, bags, and automotive interiors. Yudeng, as a professional pu leather supplier and wholesale pu leather manufacturer, leverages advanced production processes and strict quality management to maximize the value of PU materials.

1. PU Leather Core Performance Advantages

- Flexibility and Comfort: Soft surface and elastic structure maintain comfort over prolonged use, ideal for furniture and automotive seating.

- Durability: Modern PU leather resists tearing and fading, suitable for high-frequency applications like shoe uppers, handbags, and commercial furniture.

- Water Resistance and Easy Cleaning: Polyurethane coating ensures easy maintenance and reduced care costs.

- Variety in Color and Texture: PU leather supports embossing, printing, gloss, and matte finishes to match diverse design styles.

- Economical and Sustainable: Lower cost than genuine leather and free from animal materials, aligning with environmental and vegan trends.

2. Yudeng’s Manufacturing Strength

As a leading pu leather supplier, Yudeng demonstrates the following core advantages:

- Advanced Processes and Equipment: Ten production lines—including 5 dry, 3 wet, and 2 finishing lines—achieve a daily output of 150,000 meters, producing PU leather in various thicknesses (0.3–1.6 mm), textures, and performance levels.

- Strict Quality Control: Products undergo wear, water, fade, and fire resistance tests, certified with ISO 9001, GRS, REACH, RoHS, and OEKO-TEX®, ensuring safe, eco-friendly, and sustainable materials.

- Extensive Industry Experience: Serving furniture, bags, footwear, and automotive interiors for decades, Yudeng applies accumulated technical know-how to optimize production for mid- and high-end markets.

- R&D and Innovation: Over 400 texture options, including animal, stone, crocodile, snake, lychee, and bark patterns, with customizable thickness, backing, and surface treatments, guaranteeing aesthetic appeal and functional versatility.

By combining the inherent performance of PU leather with Yudeng’s robust production and R&D capabilities, brands and manufacturers gain high-quality, durable, flexible, and cost-effective materials. This enhances product competitiveness and offers end-users a comfortable, durable, and eco-friendly experience.

| Start Your order | Email: hello@fjyudeng.com | Number:+86 17746077007 |

PU leather is a durable, versatile, and stylish alternative to genuine leather for furniture, footwear, bags, and automotive interiors. Yudeng, as a trusted pu leather supplier and provider of wholesale pu leather, combines experience and advanced production to deliver high-quality, eco-friendly materials that enhance both product performance and design.