Table of contents

PU Leather Basics and Application Areas

1. Definition and Composition of PU Leather

- Definition: PU leather (polyurethane synthetic leather) is a type of artificial leather made by coating a substrate with a layer of polyurethane. It is soft, lightweight, highly versatile, and cost-effective, widely used in mid-to-high-end products.

- Composition Structure:

- Base Material: Commonly polyester fabric, cotton fabric, or knitted fabric. Different base materials affect PU leather’s softness, strength, and breathability.

- Polyurethane Coating: Determines leather’s wear resistance, water resistance, and feel.

- Surface Texture Processing: Can mimic natural leather textures or create unique patterns such as crocodile, embossing, and mirror textures.

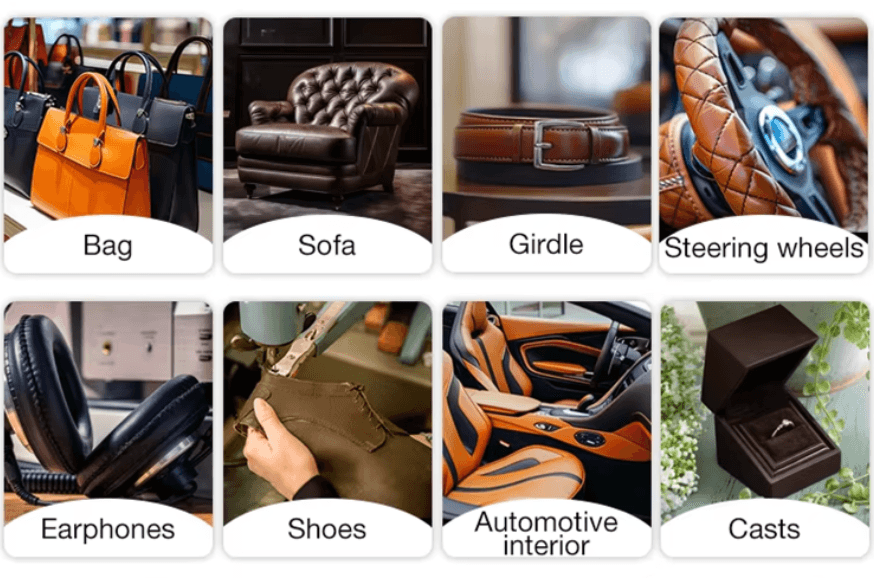

2. Main Application Areas of PU Leather

- Apparel Industry: Jackets, gloves, bags, and accessories, providing a similar feel to genuine leather while reducing animal resource usage.

- Footwear Industry: Sports shoes, casual shoes, and high-end shoes, balancing aesthetics, durability, and comfort.

- Furniture Industry: Sofas, chairs, and cushions, easy to clean, wear-resistant, and high-end in appearance.

- Automotive Interiors: Seats, armrests, and dashboards, with adjustable properties making PU leather an ideal choice.

3. Advantages of PU Leather Over Genuine Leather

- Eco-friendly: No animal skins required, reducing environmental and animal resource burdens.

- Customizable: Texture, color, thickness, and feel can be adjusted for personalized designs.

- Easy Maintenance: Stain-resistant, water-resistant, and easy to clean.

- Cost and Stability: Lower production costs, controlled color and quality, suitable for large-scale production.

International Certification Overview: CE, REACH, and Other Standards

With the continuous improvement of global trade and product safety regulations, PU leather manufacturers must pay attention to various international certifications. The main certifications include CE, REACH, and other related international standards such as ISO, Oeko-Tex, and EN71.

CE Certification

The CE mark is a mandatory certification for the European market, indicating that the product meets EU safety, health, and environmental requirements. For PU leather products, especially those related to children’s products, furniture, and automotive interiors, CE certification involves testing for chemical substance limits, fire resistance, and physical performance. For example, the EU strictly limits the content of phthalates, and PU leather production must ensure that both the coating and substrate comply with the requirements.

REACH Regulation

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is an EU regulation on the registration, evaluation, authorization, and restriction of chemicals, focusing on the impact of chemical substances on human health and the environment. Additives, flame retardants, and pigments used in PU leather must comply with the REACH restriction list (SVHC). Before exporting to the EU, companies should ensure that products pass testing by authoritative laboratories and provide a REACH compliance declaration.

Other International Standards

- ISO Standards: Such as ISO 9001 quality management system, ensuring standardized and traceable production processes.

- Oeko-Tex Standard 100: Safety testing for textiles and leather products, including harmful chemical detection, especially suitable for furniture and apparel PU leather.

- EN71: Mainly applicable to children’s toys and products, involving mechanical and chemical safety.

Through these certifications, companies can not only enhance their competitiveness in the international market but also increase brand credibility, allowing customers to purchase with confidence.

The Necessity of PU Leather Certification

Different certifications play unique roles in product safety, environmental compliance, and market competitiveness:

1. Importance of CE Certification

- It is a mandatory requirement for entering the European market, especially for PU leather products used in children’s items, furniture, and automotive interiors.

- Demonstrates that the product meets EU standards in mechanical performance, fire resistance, and harmful substance control, increasing buyer confidence.

2. Importance of REACH Regulation

- Controls chemical substances, especially plasticizers, dyes, and flame retardants in polyurethane coatings.

- Compliance reduces the risk of return or fines and proves to customers that products are environmentally safe.

3. Importance of Oeko-Tex Standard 100

- Mainly for products in direct contact with the skin, ensuring that formaldehyde, heavy metals, and other harmful substances are within safe limits.

- Enhances competitiveness in North American and European markets, meeting consumer demands for safety and health.

4. Importance of ISO Certification

- Ensures standardized, traceable production processes, improving product consistency and reliability.

- Combined with other certifications (CE, REACH, Oeko-Tex), forms a complete quality and compliance system.

Choosing a reliable pu leather manufacturer, such as Yudeng, can help ensure compliance with all certifications and maintain market competitiveness.

Yudeng: Choosing a Trusted PU Leather Supplier

When sourcing high-quality PU leather, experience, advanced technology, and reliability are crucial. Yudeng, established in 1988, has 38 years of experience in PU leather manufacturing and is a leading pu leather manufacturer and pu leather supplier in China.

1. Extensive Industry Experience and Professional Strength

- Focused on R&D, production, and sales of high-quality polyurethane PU leather, with a complete process system.

- Factory area of 100,000 m², 200 employees, equipped with 10 production lines (5 dry, 3 wet, 2 finishing), daily output up to 150,000 meters.

- Independently developed innovative formulas, ensuring PU leather is soft, wear-resistant, resilient, weather-resistant, and eco-friendly.

2. Diverse Customization Capabilities

- Texture Customization: Offers 400+ ready-made textures including animal, crocodile, snake, zebra, and mirror textures, with the option for unique client designs.

- Substrate and Thickness Customization: Polyurethane bonded to various backing materials, thickness 0.3–1.6 mm, adjustable for wear resistance and feel.

- Fast Sample and Mass Production: Urgent orders: samples in 2 days, mass production in 5 days, meeting flexible needs.

3. Comprehensive Quality Control and International Certification

- Strict quality management system ensures every meter of PU leather meets client standards.

- Factory certified with ISO 9001, products comply with REACH, RoHS, OEKO-TEX®, and hold GRS certification, ensuring environmentally friendly and sustainable production.

By partnering with Yudeng, customers gain high-quality, eco-friendly, and durable PU leather products with professional customization services and complete international certification support.

Frequently Asked Questions

During PU leather procurement and certification, customers often have some common questions:

1. Certification FAQs

- Q: Is it necessary to obtain both CE and REACH certifications?

A: For exporting to the EU, both CE and REACH compliance is usually required, especially for PU leather used in children’s items and furniture. - Q: Does Oeko-Tex Standard 100 apply to all PU leather?

A: Mainly for products in contact with skin, such as apparel, sofas, and automotive seats, ensuring chemical safety.

2. Customization FAQs

- Texture or color mismatch: Use standard samples to confirm the process and strictly control coating thickness and embossing parameters during mass production.

- Improper substrate causing poor feel: Choose appropriate polyester or knitted base material based on application, combined with coating adjustments to achieve desired softness and wear resistance.

| Start Your order | Email: hello@fjyudeng.com | Number:+86 17746077007 |

This article introduces PU leather basics, international certification standards, and their necessity, highlighting Yudeng as an experienced pu leather manufacturer and pu leather supplier. With 38 years of industry experience, abundant texture options, customization capabilities, and international certifications, Yudeng provides high-quality, eco-friendly, and reliable PU leather products.

Whether for apparel, footwear, bags, home décor, or automotive interiors, choosing Yudeng ensures compliance with international standards and enhances market competitiveness. Contact Yudeng to learn more or request customized samples for a professional, fast, and trustworthy PU leather solution.