Table of contents

Understanding PU Leather: Composition and Types

PU leather, or polyurethane synthetic leather, is a highly valuable material in modern manufacturing. It consists of a polyurethane coating layered onto a base substrate, typically cotton, polyester, or synthetic fiber fabric. The polyurethane coating provides a texture and feel similar to genuine leather. Compared to natural leather, PU leather is cost-effective, environmentally friendly, and easy to maintain, making it widely used in furniture, apparel, footwear, handbags, and automotive interiors.

Common Types:

- Glossy PU Leather: Smooth and shiny surface, commonly used for sofas, handbags, and car seats, providing a premium look.

- Embossed PU Leather: Texture is pressed onto the surface using molds, simulating natural leather or creating unique patterns, suitable for shoes and fashion accessories.

- Suede PU Leather: Matte finish with a soft touch, widely applied in apparel, sofas, and fashion items.

- Elastic PU Leather: Incorporates a flexible layer or substrate, enhancing stretchability and durability, ideal for sports shoes and bags.

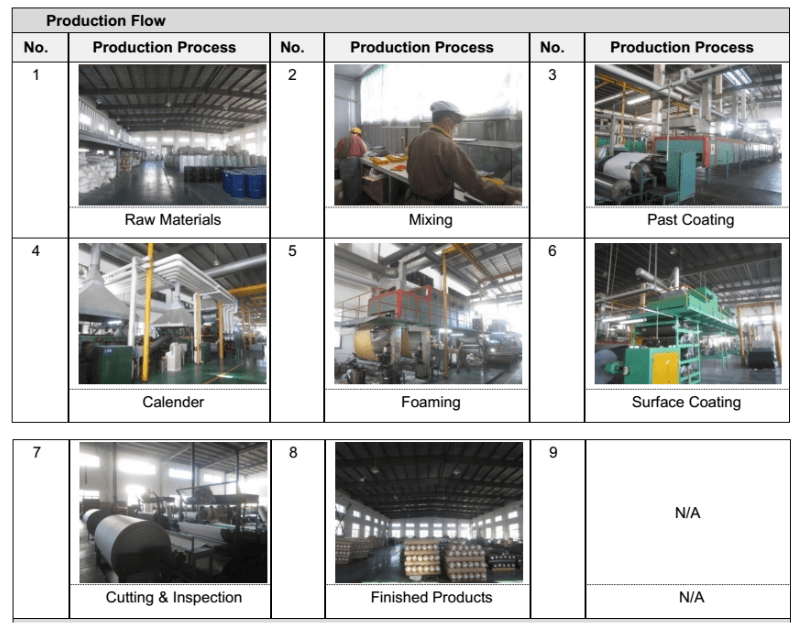

Manufacturing Process: From Raw Materials to Finished PU Leather

The manufacturing process of PU leather determines its quality and performance. The overall workflow includes raw material selection, coating preparation, lamination, and surface finishing. Yudeng, as an experienced pu leather manufacturer, with over 30 years of experience, utilizes advanced coating equipment and rigorous quality control to deliver high-quality PU leather and pu leather supplier services.

1. Raw Material Selection

- Polyurethane Liquid or Powder: Primary coating material; its chemical composition determines the leather’s flexibility, abrasion resistance, and hand feel.

- Base Substrate: Yudeng offers cotton, polyester, or non-woven polyester fabrics; substrate choice affects strength, thickness, and elasticity.

- Auxiliary Materials: Plasticizers, stabilizers, dyes, and coating aids ensure surface gloss, color consistency, and durability.

2. Coating and Lamination

- Coating: Yudeng uses precision coating machines to apply polyurethane evenly, controlling thickness typically between 0.1–0.5mm.

- Drying and Curing: Heat treatment ensures the polyurethane forms a uniform film with strong adhesion and abrasion resistance.

- Multi-Layer Coating: Yudeng applies bottom reinforcement, middle cushioning, and top decorative layers to meet high-intensity usage requirements.

3. Surface Treatment

- Embossing: Molds create textures that mimic natural leather or custom designs.

- Coloring and Printing: Yudeng achieves uniform or gradient colors using eco-friendly dyes.

- Topcoat: Anti-UV, waterproof, and anti-stain coatings enhance durability.

4. Quality Control and Testing

- Thickness Measurement: Digital gauges ensure consistent thickness per square meter.

- Abrasion Resistance: Martindale or Taber testers evaluate wear performance; Yudeng’s PU leather withstands over 50,000 cycles, suitable for heavy-duty applications.

- Tensile and Tear Tests: Guarantee resistance to cracking or splitting during use.

These processes allow Yudeng to deliver PU leather that meets ISO9001 and Oeko-Tex certifications while providing high-quality pu leather supplier services.

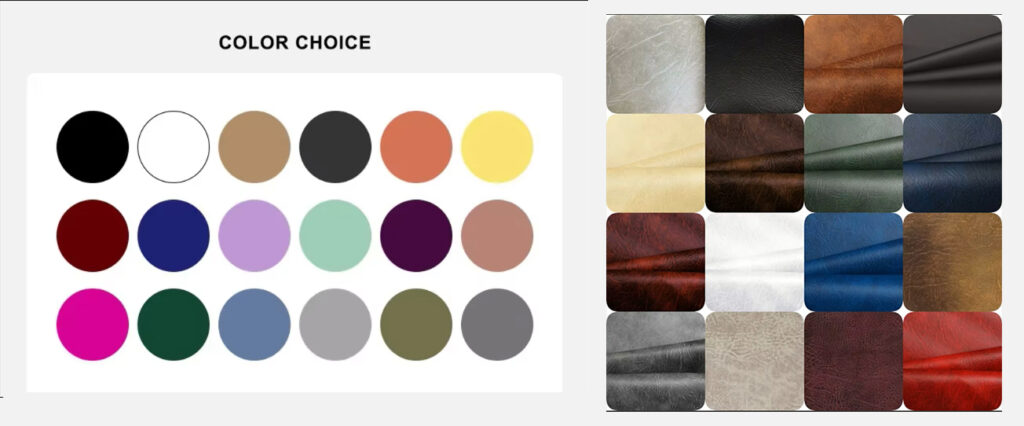

Customization Options: Texture, Color, and Substrate

Modern PU leather manufacturing emphasizes both functionality and aesthetics. Yudeng, as a professional pu leather manufacturer, offers extensive customization options, tailoring PU leather texture, color, and substrate to meet diverse client needs, while also providing pu leather supplier services.

Texture Customization

- Embossed Patterns: Yudeng can replicate natural leather, crocodile skin, or scale textures.

- Printing: Screen or digital printing allows personalized patterns for unique designs.

- Suede/Velvet Surfaces: Adjusts surface feel for softness or premium texture.

Color Customization

- Single colors, gradients, or metallic finishes are available to meet fashion, home, or industrial needs.

- Eco-friendly dyes ensure color fastness and light resistance; clients can approve samples to guarantee consistency in bulk production.

Base Substrate Customization

- Cotton Fabric: Soft and comfortable, suitable for apparel and lightweight furniture.

- Polyester Fabric: High strength and wear resistance, ideal for shoes, bags, and heavy-use products.

- Non-Woven Polyester: Lightweight and elastic, suitable for tech product cases or soft furnishings.

Yudeng’s professional team provides small-batch sampling and rapid production, allowing clients to verify texture, color, and feel, ensuring high-quality pu leather supplier bulk delivery.

Practical Applications: Versatile Uses of PU Leather

PU leather’s excellent performance and customizability make it widely applicable across industries. Different applications demand varying levels of durability, flexibility, and aesthetics.

1. Home Furnishings

- Sofas and Chairs: Medium-thickness, wear-resistant PU leather with embossed or glossy surfaces enhances visual appeal.

- Wall Panels: Suede or embossed textures add dimension while remaining easy to clean.

2. Fashion Apparel and Accessories

- Footwear: Lightweight, elastic, and durable PU leather is ideal for sneakers and casual shoes.

- Bags: Custom textures and colors create personalized designs with wear and stain resistance.

3. Automotive Interiors

- Seats and panels use high-abrasion, UV-resistant PU leather, preventing fading or cracking.

4. Tech Product Cases

- Suitable for phone cases, laptop sleeves, and headphone cases, offering comfort, protection, and easy cleaning.

PU Leather Advantages and Limitations

Although PU leather offers many benefits, it has some limitations. Understanding both is key to selecting the right material.

Advantages

- Cost-Effective: PU leather is 30–50% cheaper than genuine leather, suitable for mass production.

- Environmentally Friendly: No animal hides are required, supporting sustainable practices.

- Durable: Proper coating allows daily wear resistance exceeding 50,000 cycles.

- Easy Maintenance: Water and stain-resistant; cleanable with a damp cloth.

- Highly Customizable: Texture, color, and substrate can be tailored for individual needs.

Limitations

- Limited Breathability: Less breathable than genuine leather, may be less comfortable for prolonged skin contact.

- Low Heat Resistance: Can soften or deform under high temperatures.

- Shorter Lifespan: Typically 3–5 years, high-quality PU leather may last up to 7 years but still less than premium natural leather.

- Prone to Cracking: Low-quality PU leather can crack when dry or frequently folded.

| Start Your order | Email: hello@fjyudeng.com | Number:+86 17746077007 |

PU leather, with its low cost, customizability, easy maintenance, and eco-friendliness, has become an indispensable material in modern manufacturing and design. By understanding its composition, manufacturing process, customization options, and applications, users can select the right PU leather for their projects, achieving high cost-performance and premium visual appeal.

With professional pu leather manufacturer expertise and reliable pu leather supplier services, businesses and designers can fully utilize PU leather’s potential, delivering materials that meet functional needs while enhancing overall project quality and user experience.